Introduction

The BANDAR ABBAS Refinery is one of the most important and largest industrial projects in IRAN’s oil and gas sector, established in Hormozgan province, near Bandar Abbas, with a daily refining capacity of 300,000 barrels of crude oil. This refinery commenced operations in 1998 and plays a significant role in supplying fuel and petroleum products for the country. Due to its strategic geographical location next to the Persian Gulf, it has easy access to international waters and commercial ports, making it a key center for the export and import of petroleum products.

The BANDAR ABBAS Refinery pursues multiple objectives, including meeting the domestic demands for refinery products and fossil fuels. Equipped with various units, such as gasoline, diesel, fuel oil, and other primary products, it plays a crucial role in supplying fuel for industries and transportation across the country.

Moreover, in light of environmental requirements and international standards, the BANDAR ABBAS Refinery is particularly committed to optimizing production processes and reducing pollution. Modern technologies, along with the implementation of advanced monitoring and control systems, enable the refinery to maintain product quality while minimizing negative environmental impacts.

Leveraging these features and capabilities, the Bandar Abbas Refinery is recognized as one of the most successful and pioneering oil refining units in the country, significantly contributing to Iran’s economic and industrial development.

Benzene Assessment

The benzene recovery unit at the Bandar Abbas Refinery operates efficiently, recovering benzene with the highest efficiency and minimal energy consumption. Utilizing advanced processes and modern technologies, it can continuously supply the benzene required by various industries under different operational conditions. By reducing emissions of pollutants into the environment, this unit contributes to environmental preservation and sustainable development goals.

Additionally, the strategic location of the Bandar Abbas Refinery allows for the export of recovered products, including benzene, to global markets. This not only aids in increasing the country’s foreign exchange revenues but can also pave the way for attracting foreign investments and transferring new technologies to Iran.

The Bandar Abbas Refinery continually conducts research and planning to enhance the quality and efficiency of its units. This approach ensures that the refinery is recognized as one of the leaders in the industry in Iran and the region, playing an essential role in meeting domestic needs and reducing dependency on imported raw materials. Ultimately, the Bandar Abbas Refinery and its benzene recovery unit exemplify the synergy between technology, environment, and economy in Iran’s refining industry, and it is hoped that these sustainable approaches will continue in the future.

Advantages

The economic recovery of benzene at the Bandar Abbas Refinery using Comfar software encompasses several key advantages. Firstly, comprehensive financial analysis capabilities enable decision-makers to evaluate project costs and revenues more knowledgeably, thereby minimizing financial risks. Secondly, utilizing this software facilitates clarity regarding the payback period and profitability of the project, which is vital for attracting investors and creditors. Additionally, Comfar aids in sensitivity analysis and assessing various economic scenarios, allowing project managers to plan better to address challenges. Moreover, focusing on environmental aspects and sustainability improves the project’s image among stakeholders and the community, ultimately leading to sustainable financing and the long-term success of the project.

Another advantage of using Comfar in the economic assessment of benzene at the Bandar Abbas Refinery is its ability to provide reports and visual analyses that assist managers and stakeholders in making better decisions. This allows all stakeholders to easily understand the necessary information and stay informed about the project’s financial conditions and performance. Furthermore, the ability to compare the project with others and similar scenarios helps analysts identify the project’s strengths and weaknesses, designing more optimal strategies based on these insights.

Ultimately, this approach leads to resource optimization and increased operational efficiency, contributing to added value for the Bandar Abbas Refinery while improving its competitive position in the market. In summary, leveraging Comfar can transform the management and economic planning of refinery projects and support the realization of strategic and economic goals.

Cost and Revenue Analysis

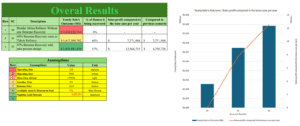

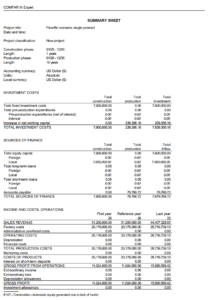

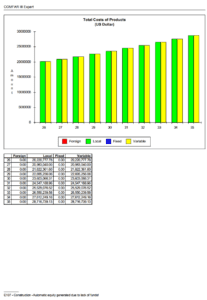

The economic assessment of benzene at the Bandar Abbas Refinery is crucial for evaluating the financial and economic viability of this project. Using Comfar software aids in the precise analysis of costs, revenues, and risks associated with benzene production, facilitating more informed decision-making for managers and investors. As an advanced analytical tool, Comfar enables managers to closely examine the financial and economic patterns of projects and evaluate them from various perspectives. Using Comfar in cost and revenue analysis reveals how the initial investment costs, operational costs, and revenue structure of the project are structured. This analysis includes estimating raw material costs, labor, maintenance, and repair costs, along with forecasting revenues from benzene sales. A thorough understanding of these factors allows managers to make better decisions regarding financing and production scheduling.

Investment Return Assessment

Comfar enables managers to accurately estimate the return on investment (ROI) for the benzene project. By examining cash flow tables and financial forecasts, it can be determined when the project will reach profitability. This information is crucial for attracting investors and creditors, as they seek projects with the quickest possible returns.

Risk Identification and Management

Risk management is a critical aspect of any economic project. Comfar helps analysts identify various risks such as raw material price fluctuations, market changes, and legal issues, enabling the development of appropriate strategies for managing and mitigating these risks. A thorough evaluation of risks allows managers to plan effectively and prevent future problems.

Sensitivity Analysis and Various Scenarios

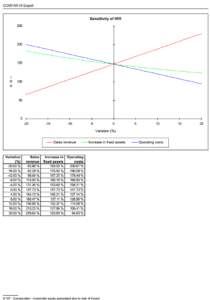

Comfar’s sensitivity analysis capability enables analysts to assess the impact of changes in key parameters such as selling prices, production costs, and market growth rates. This analysis helps managers examine different scenarios and develop the best strategies for enhancing profitability and improving project performance. Evaluating various scenarios leads to better decision-making outcomes.

Process Description

The economic assessment of benzene at the Bandar Abbas Refinery using Comfar software is conducted comprehensively and thoroughly. This software allows users to simulate refinery projects, examining costs, revenues, and various financial aspects. In the benzene recovery process, streams containing benzene are first transferred to the recovery unit. Then, advanced separation technologies are employed to isolate high-purity benzene from other compounds. Comfar assists in assessing parameters such as operational costs, initial investments, revenue from benzene sales, and maintenance costs, helping determine the economic justification and profitability of the project.

Since benzene is a vital raw material in the refining and chemical production industries, recovering and utilizing this valuable substance at the Bandar Abbas Refinery not only helps reduce resource wastage but also increases revenue generation and added value for the facility. By utilizing data from Comfar, the refinery can plan better for developing its units and optimizing production processes. Ultimately, these actions will enhance the competitiveness of the Bandar Abbas Refinery in both domestic and global markets.

Continued use of Comfar software at the Bandar Abbas Refinery, particularly in the context of benzene assessment, significantly aids these processes:

By simulating various scenarios, the software can analyze market sentiments and benzene price fluctuations. For instance, with changes in global oil prices or economic fluctuations, the Bandar Abbas Refinery can predict the impact on revenues and costs. Such in-depth analyses enable refinery management to make smarter decisions and adopt suitable strategies to maintain profitability during critical times.

Moreover, optimizing energy and raw material consumption is another benefit of executing analytical projects with Comfar. By identifying weaknesses in existing processes and implementing necessary changes, the Bandar Abbas Refinery can enhance the efficiency of its benzene recovery unit and ultimately reduce production costs.

In conclusion, this analytical approach and the use of Comfar software empower the Bandar Abbas Refinery to emerge as a regional player in the refining industry and contribute to sustainable growth and economic development in Iran. Given the significance of benzene in producing various refining products, this assessment process positively impacts the production capacity of this facility while significantly aiding in meeting market needs and reducing dependence on imports. Consequently, the Bandar Abbas Refinery can effectively contribute to the development of the country’s refining industry and play a vital role in the national economy.

Conclusion

The economic assessment of benzene at the Bandar Abbas Refinery using Comfar software demonstrates that this tool aids in accurately analyzing project costs and revenues and facilitates the estimation of the payback period. By evaluating related risks and providing comprehensive information, Comfar can attract investors and creditors and encourage them to participate in the project. Moreover, focusing on environmental sustainability and development issues in project design can create a more positive public image of it and ease social acceptance. Ultimately, deriving conclusions from these analyses can lead to key decision-making and the long-term success of the benzene project at the Bandar Abbas Refinery.

To enhance the performance and efficiency of the benzene assessment unit at the Bandar Abbas Refinery, ANILCO has conducted comprehensive simulation and optimization studies on the key equipment and processes of this unit, including:

– Feasibility Study and Benzene Recovery at the Persian Gulf Star Oil Refinery Using Comfar

– Simulation and Optimization of Benzene Recovery at the Persian Gulf Star Refinery Using Aspen HYSYS

– Optimization of the CCR Unit at the Persian Gulf Star Refinery with the Conceptual Design of a Novel Unit

Feasibility Study and Economic Assessment of Benzene at the Bandar Abbas Refinery Using Comfar

In this project, the feasibility study and economic assessment of benzene at the Bandar Abbas Refinery have been conducted using Comfar.