Introduction

The detailed engineering, procurement, and installation of Process Tower 42T-15005B and auxiliary equipment are crucial steps in the development and enhancement of efficiency in petrochemical and chemical processing units. Today, the petrochemical industry faces increasing challenges, including the need for energy optimization, increased production efficiency, and improved product quality. Process towers play a significant role in the separation and purification of raw materials.

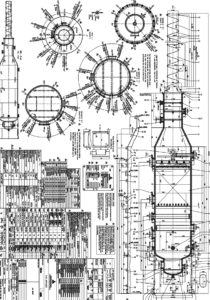

Process Tower 42T-15005B, serving as a distillation unit, features a unique design and capabilities that contribute significantly to the optimization of separation processes. Equipped with advanced temperature, pressure, and flow control systems, this tower is designed to meet specific production needs. The detailed engineering process includes precise technical analyses, material selection, mechanical and electrical design, and necessary simulations to predict the tower’s performance under real conditions.

The procurement and provision of auxiliary equipment and services are also vital stages of this project. Auxiliary equipment includes pumps, valves, controllers, and safety systems, directly related to the tower’s performance. Moreover, installing and commissioning this equipment require meticulous planning and coordination among various technical teams to ensure all systems operate correctly and efficiently.

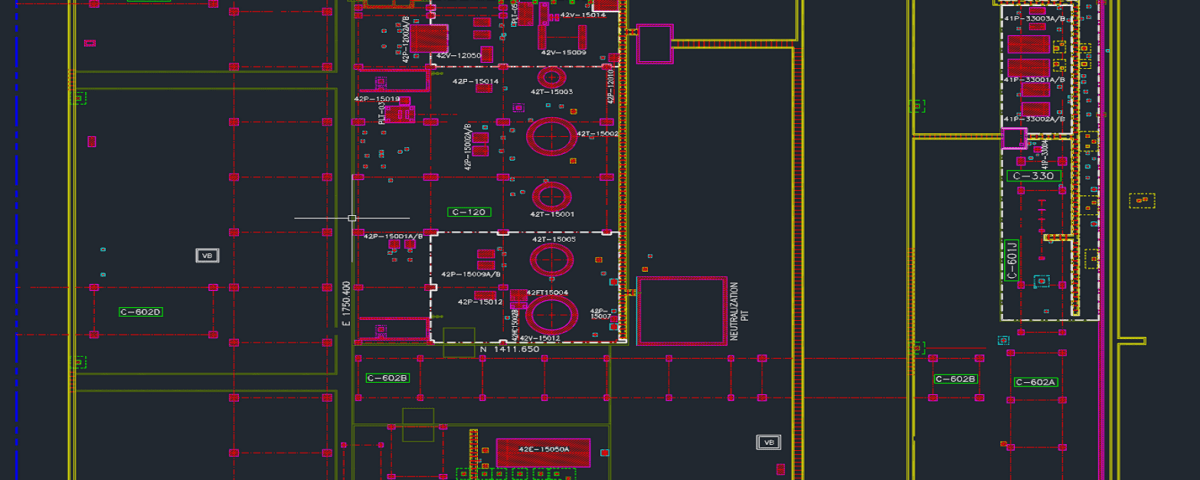

Input Feed to Unit 150

The feed for this unit consists of a mixture of liquid gas VCM/HCl/EDC from the EDC cracking system (Unit 140) and VCM recovery from the top of the stripper tower (42T-15003).

Introduction to Unit 150 Towers

HCl Tower:

This tower features valve tray trays with two-pass trays on the lower section and one-pass trays on the upper section. Its condenser supplies the refrigerant fluid from the refrigeration section (refrigerant fluid is propylene). The Reflux drum of this tower has sufficient capacity to store HCl produced in Unit 140 (cracking) when the unit Oxy reactor (unit 120) is temporarily out of service.

VCM Stripper Tower:

These two towers have sieve type trays and use Reboilers and reflux systems.

Reactor Type:

The reactor of this unit is located in the Recycle EDC Chlorination section. Additionally, a safety scrubber system exists in this unit.

Process Description

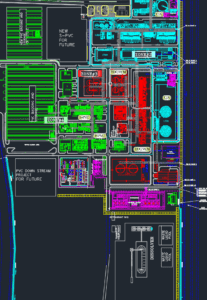

Unit 150, also known as the VCM Purification Unit, includes the following equipment for purifying WCM from the cracking product in the furnaces of Unit 140:

– HEL column 42T-15001

– VCM column 42T-15002

– VCM Stripper 42T-15003

– Recycle EDC Chlorination System (consisting of chloroform chlorination 42U-15010 and benzene chlorination 42R-15001)

HCl Tower:

HCl Tower (42T-15001) is designed to separate high-purity HCl from the output of the furnaces. High-purity HCl vapor exits from the top of the tower and is partially condensed in the condenser.

Liquid HCl is stored in an insulated tank and used as a reflux source for the tower. The portion of the HCl product that is unconverted is sent as feed to Unit Oxy 120.

The feed for this tower comes from the outflows from the top and bottom of the quencher in Unit 150, as well as the VCM containing HCl from within Unit 150 (VCM recovery from the top of the stripper).

VCM Tower:

In this tower, the VCM product exits from the top, while the bottom product includes unconverted EDC and by-products, which are sent to the chlorination section for EDC recycling.

In the EDC Recycle Chlorination section, by-products with low boiling points like gasoline and chloroprene are converted to higher boiling point materials.

Conclusion

The detailed engineering project for the procurement and installation of the process tower and ancillary equipment was executed with the active participation of Process Industry Anil Pars. Our company participated in the project tender, leveraging our technical and engineering expertise to fully implement the project. The precise selection of equipment and adherence to quality standards during the procurement and installation phases maximized the tower’s performance and efficiency, consequently leading to reduced operational costs. This project not only contributed to achieving technical and economic objectives but also laid the groundwork for continuous improvements in future operational processes.

Engineering and Procurement of Process Tower 42T-15005B

Process Industry Anil Pars proudly announces its participation in the tender for a project with a reputable company. We have fully implemented the technical proposal, preliminary design, and EPC execution engineering for this project, which was defined in a comprehensive framework for the client. For more information, please contact us.