Introduction

Pollution from gasoline and diesel engines in various industries and transportation represents the most significant environmental challenge facing humanity today. With the increasing global demand for energy and the limitations of fossil fuels, there is a pressing need for recycling and optimal utilization of resources, employing various materials and techniques. Various feedstocks, such as straw, corn, sugarcane, grasses, leaves, household organic waste, and food waste, can potentially be converted into valuable biofuels.

One partial solution to issues related to petroleum is the conversion of agricultural biomass to ethanol, which is noteworthy for several reasons:

– Cheap and accessible raw materials

– Value-added processes

– Reduction of air pollution and global warming

– Advantages of biofuels

Biofuels, in general, are considered a clean fuel with advantages over fuels derived from crude oil, including:

– Absence of heavy compounds and sulfur oxides

– Approximately 50% lower nitrogen oxide emissions compared to other fuels

– Easier handling, pumping, and storage

– Prevention of environmental pollution

Based on these advantages, large-scale production of bioethanol using cellulase enzymes presents both economic and environmental benefits.

Background on Cellulose Production

The primary step in producing ethanol from biomass is converting complex carbohydrates in plants into simple sugars through a process known as saccharification, which can then be fermented by microorganisms. When using fibrous biomass, the saccharification process is predominantly carried out by cellulase enzymes.

Enzyme Production Methods

The enzymes used in commercial applications are produced through submerged fermentation (SmF), where microorganisms are cultivated in a nutrient-rich aqueous medium. An alternative to the traditional SmF method is solid-state cultivation (SSC), where microorganisms grow on solid substrates in the absence of free liquid. Given that SSC uses less liquid than SmF, the downstream processing of SSC is theoretically simpler and cheaper.

Comparison Between SmF and SSC Methods

From an economic perspective, the SSC method offers at least three advantages over the traditional SmF method for enzyme production:

1. Lower water and energy consumption

2. Reduced waste generation

3. Higher product concentration

The SSC method requires less reactor capacity and lower operating costs compared to the old SmF method. Although there are intrinsic advantages in the SSC method, technical issues limit its large-scale implementation. For instance, due to restricted diffusion in the solid substrate, mass and heat transfer are more challenging in SSC than in SmF. Heat accumulation and decreased oxygen availability, if uncontrolled, can lead to the cessation of activity in mesophilic aerobic microorganisms, subsequently halting enzyme production.

One approach to overcoming the mass and heat transfer issues is to use organisms that can withstand higher temperatures and anaerobic conditions. Studies have shown that certain thermophilic anaerobic bacteria can grow using SSC. Notably, Clostridium thermosaccharolyticum appears promising due to its substantial cellulase production.

Biofuel Production Process Simulation

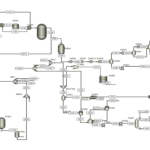

The production process using both SSC and SmF methods has been simulated. The equipment considered for the economic calculations is specified in the figure below.

Economic Analysis

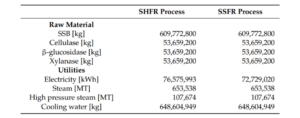

The economic costs calculated for raw materials and utilities are referenced in the table below:

The economic analysis examines fermentation in three segments: input (cellulosic feedstock), growth medium (media), and output (new bacteria, final cellulase product, and fermentation end products (FEP)), where the mass balance equation is observed:

Cellulosic feedstock (500,000 kg) → New bacteria (50,000 kg) + Final cellulase product (10,000 kg) + FEP (440,000 kg)

Based on conducted experiments, a cellulose-to-bacteria conversion ratio of 1 to 10 has been assumed, meaning that for the growth of 50,000 kg of new bacteria, 500,000 kg of cellulose must be consumed.

Conclusion

Utilizing alternative fuels in various energy-intensive industries not only enhances resource efficiency but also contributes to the optimal allocation of these resources, energy security, and environmental sustainability. Additionally, the raw materials used are inexpensive and widely available, facilitating the process. This study investigated a process for biofuel production using two methods: SSC and SmF.

Economic Analysis and Simulation of Biofuel Production Unit in Aspen Plus

In this project, economic analysis and simulation of biofuel production processes have been conducted using Aspen Plus version 11.