Introduction

Ethyl acetate production line is one of the most profitable chemical production lines, which has different stages for its construction and operation. Among them, we can mention the review of the justification plan, the review of the market situation. the review of the relevant licenses, the selection of technical knowledge, etc. This substance is colorless and has a fruity smell with the chemical formula C4H8O2.

The molar mass of this compound is 88.106 g/mol with water solubility of 33.0 grams per 100 ml of water. The boiling point of ethyl acetate is 77.1 and its melting point is -83.6 degrees Celsius. This substance is flammable and explosive, and MSDS studies of the substance and HSE of the process should be done in the ethyl acetate production line before working with this substance.

In general, chemical industries are profitable industries. But to reduce the investment risk factor and ensure profitability the ethyl acetate production line is more suitable for economic operators in the following areas:

Ethanol Producers

Since the ethanol production line equipment has many points in common with the ethyl acetate production line. high quality ethyl acetate can be produced with few changes in the ethanol production line.

Owners of Factories With Steel Distillation Towers

Since the main investment cost of the ethyl acetate production unit is related to the distillation tower and its thermal system. the owners of factories with steel distillation towers will be able to produce high quality ethyl acetate with a small cost.

Consumers of Ethyl Acetate

The market is one of the important pillars of the profitability of chemical factories. Consumers of ethyl acetate will be profitable for this industry due to having a guaranteed market.

Businessmen Who Have Experience in This Field or Have Good Knowledge of This Industry

Due to the experience they have had in this field. the businessmen of this field are in contact with various people who can be the profitable links of the ethyl acetate industry.

Description of The Process

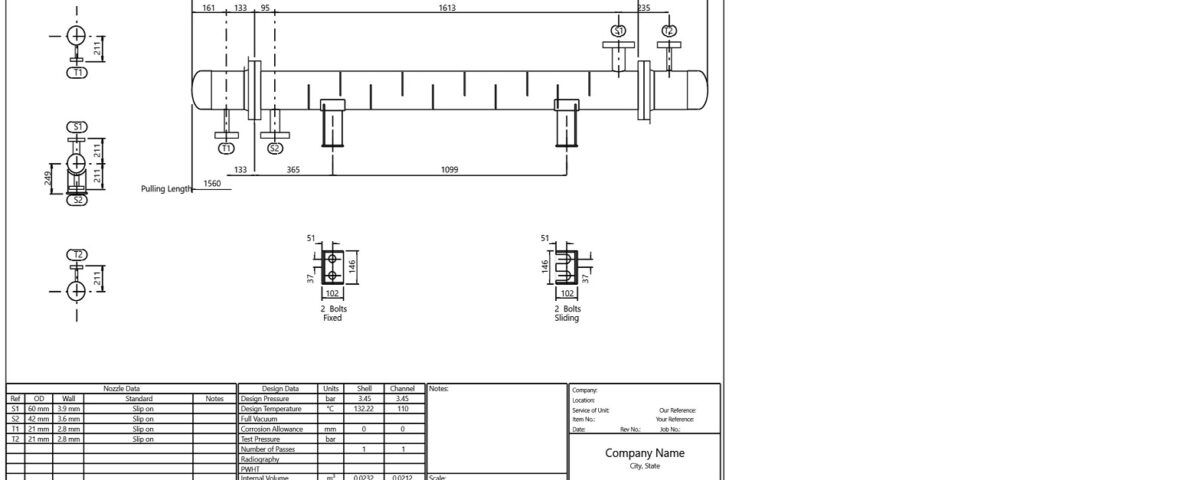

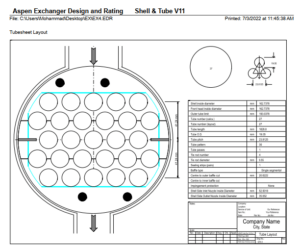

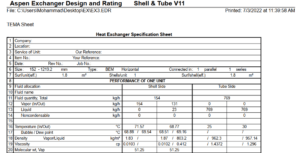

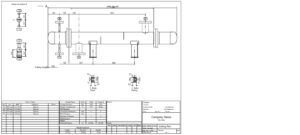

The following pictures are related to the converters of the ethyl acetate production unit with a capacity of 2400 tons per year.

Conclusion

Designing and building an ethyl acetate production line requires careful consideration of process needs, equipment selection, safety measures, and regulatory compliance. Below is an overview of the equipment:

1. Reactors:

Ethyl acetate or ethyl ester is usually produced via esterification, where the alcohol ethanol reacts with acetic acid in the presence of a catalyst. The main equipment required depending on how the reaction is carried out may be a batch reactor or CSTR. The reactor should be made of corrosion-resistant materials such as stainless steel and equipped with a suitable stirrer and temperature control mechanism.

2. Distillation tower:

After the esterification reaction, the mixture is separated using distillation operation. Distillation towers such as packed or tray towers are used to separate and purify ethyl ester from other materials. These towers contain several trays or packings to facilitate the separation process.

3. Condensers:

The vapor of this substance needs to be converted into a liquid state during the distillation process. Shell-tube condensers or plate heat exchangers are usually used for this purpose. Cooling water is used to reduce the temperature and convert the vapor into liquid phase.

4. Separation and purification units:

sometimes more separation units are needed to remove impurities and further purification and higher purity. These units can include techniques such as liquid-liquid extraction, molecular sieves or membrane filtration.

5. Storage tanks:

After purification, this material is stored in tanks. These tanks should be made of suitable materials such as carbon steel or stainless steel and attention should be paid to safety features such as pressure relief valve and level indicator.

6. Tools and infrastructure:

The production line requires tools such as steam boilers, pumps and measuring systems to control the process. Adequate infrastructure including plumbing, electrical and air conditioning systems must be designed to ensure safe and efficient operation of the production line.

Designing Converters for Ethyl Acetate Production Unit

In this project, the design of the converters of the ethyl acetate production unit with a capacity of 2400 tons per year has been done.