Description

Pressure Filters in Industry: A Gateway to Clean Fluids

Pressure filters are indispensable equipment in various industries, employed to separate solid particles from fluids. By applying pressure to the fluid, these filters trap the particles within a porous medium, allowing the purified fluid to pass through. This article delves into the types, operation, advantages, and applications of pressure filters in diverse industries.

Types of Pressure Filters

Pressure filters can be categorized based on the filter media, material of construction, and specific application. Some common types include:

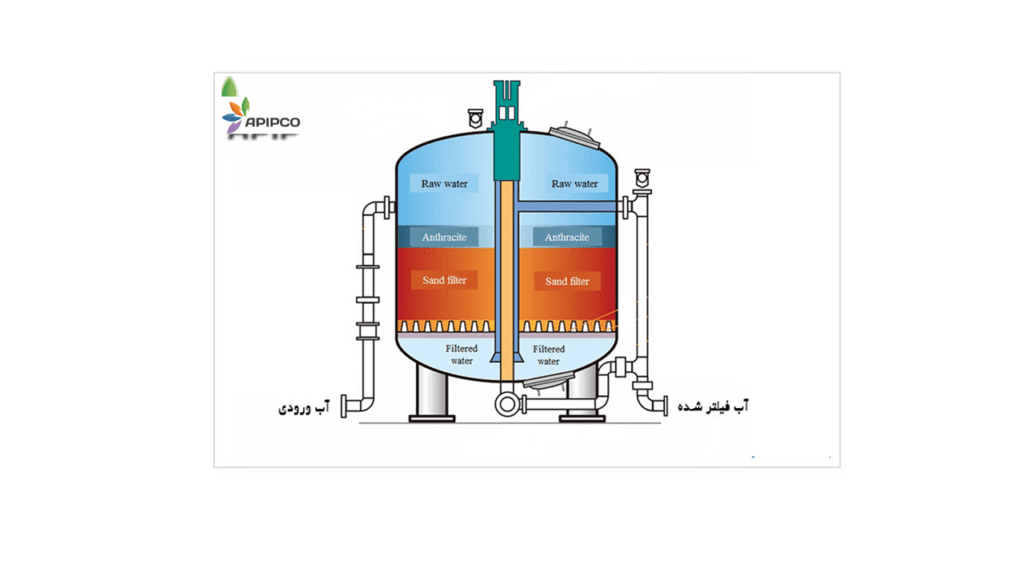

- Sand filters: The most prevalent type of pressure filter, utilizing a bed of sand to capture particles.

- Multi-media filter: A combination of several types of filter media (such as sand, anthracite, and activated carbon) to remove a wide range of contaminants.

- Microfiber filter: Used to remove very fine particles and bacteria.

- Membrane filter: Uses very fine membranes to separate molecules and very small particles.

- Carbon filter: Used to remove organic matter, odor, and unpleasant taste from water and other fluids.

Designing Industrial Filters with SolidWorks: A Step Towards Precise Fluid Filtration

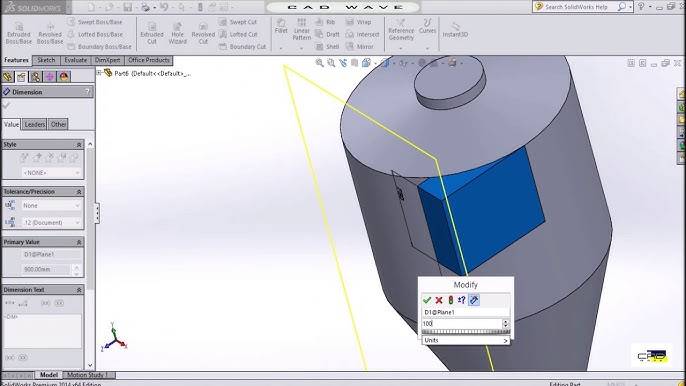

SolidWorks, a powerful 3D CAD software, is a valuable tool for mechanical and chemical engineers designing industrial filters. Using this software, highly accurate and realistic models of various filter types can be created, allowing for the simulation of filtration processes.

Why SolidWorks is suitable for filter design:

- High accuracy: Creating highly detailed 3D models.

- Flexibility: Easily making design changes.

- Facilitation of manufacturing: Producing accurate manufacturing drawings.

- Cost reduction: Reducing manufacturing and testing costs through simulation.

- Performance improvement: Optimizing filter design for increased efficiency and reduced pressure drop.

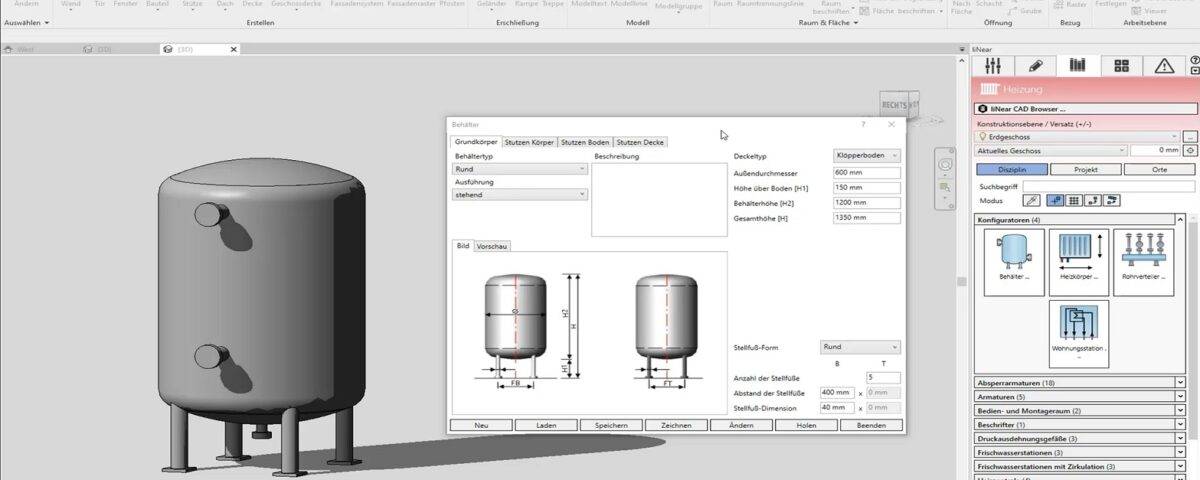

Drafting and Fabrication of a Pressure Filter

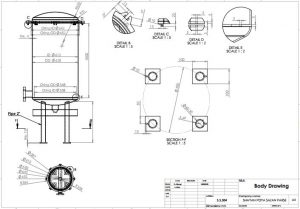

This project involved the design of a pressure filter using SolidWorks software. The accompanying figure provides a visual representation of a portion of the design , The design was focused on the development of a pressure filtration system, a critical component in many chemical engineering processes.

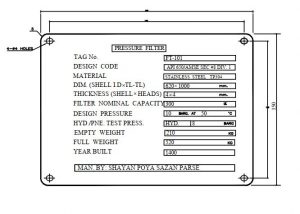

The figure below shows the tag plate on the filter.

Conclusion

Designing industrial filters with Solidwork software is an accurate, efficient and flexible method for creating 3D models of different types of filters. This software allows engineers to design filters in full detail that can meet the needs of various industries.