Introduction

Ethanol, also known as ethyl alcohol, is a versatile chemical compound with widespread applications in various industries, including biofuels, food, and pharmaceuticals. However, producing high-purity ethanol presents significant challenges. One of the primary obstacles in ethanol production is its separation from water due to the formation of an azeotrope.

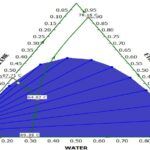

An azeotrope is a mixture with a constant boiling point, making it difficult to separate its components through simple distillation. In the case of ethanol, the ethanol-water azeotrope typically contains around 95.63% ethanol by weight, rendering traditional distillation methods ineffective for further purification. To address this issue, several methods have been developed, one of which is heterogeneous dehydration of ethanol. This method involves using a third component, or solvent, to break the azeotrope and facilitate separation. The selection and use of an appropriate solvent can significantly impact process efficiency, operating costs, and energy consumption.

Process Description

Ethanol dehydration is a process aimed at separating ethanol from water to produce a higher purity ethanol product. Due to the formation of an azeotrope between water and ethanol (typically around 95.63% ethanol by weight), conventional separation methods such as simple distillation become ineffective. To overcome this limitation, heterogeneous dehydration is employed. This technique involves introducing a third component, or solvent, into the mixture to break the azeotrope and facilitate the separation process.

Process Steps

The heterogeneous dehydration process generally consists of the following stages:

-

Pre-concentration: In this initial stage, the aqueous ethanol mixture is fed into a primary distillation column. The purpose of this column is to increase the concentration of ethanol in the feed stream.

-

Azeotropic Distillation: To disrupt the azeotrope and enhance separation, an solvent is introduced into the distillation system. The solvent forms a new azeotrope with one of the original components (either ethanol or water), allowing for the separation of the desired product.

-

Solvent Recovery: In this final stage, the solvent is recovered from the process streams and recycled back to the azeotropic distillation column. This step is essential to ensure efficient utilization of the solvent and minimize process costs.

Aspen Plus Simulation

In this project, Aspen Plus, versions 10 and 12, was utilized to simulate the heterogeneous dehydration of ethanol. The following sections provide a detailed account of the simulation process, including the selection of thermodynamic models, the adjustment of operational parameters, and a comprehensive analysis of the results.

Initial Simulation Steps:

Component Definition: The primary constituents of the mixture, namely ethanol, water, and the chosen solvent(such as benzene), were defined within the simulation software.

Thermodynamic Model Selection: The Non-Random Two-Liquid (NRTL) model was selected for its demonstrated accuracy in predicting the phase behavior of azeotropic mixtures. This model is particularly well-suited for systems exhibiting non-ideal behavior, which is characteristic of azeotropic mixtures.

Physical Property Input: Essential thermodynamic data, including enthalpy of vaporization, activity coefficients, and parameters specific to the NRTL model, were input for each component. These data are crucial for accurately representing the thermodynamic behavior of the system.

Operating Condition Specification: The operational temperature and pressure were defined for each process section. These parameters significantly influence the phase equilibrium and separation efficiency within the system.

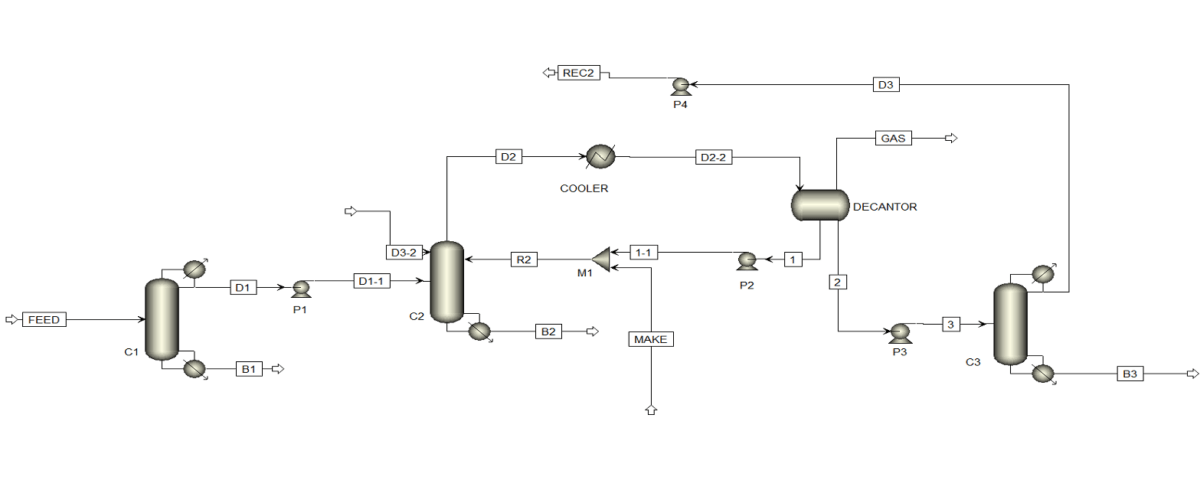

Simulation Description

The heterogeneous dehydration of ethanol involves multiple stages, each of which was individually simulated using the software. The most critical components of this process include the pre-concentration column, the azeotropic distillation column, and the solvent recovery column.

Pre-concentration Column Modeling The pre-concentration column is responsible for increasing the ethanol concentration. In this stage:

- Column Definition: The number of trays, column height, diameter, and type of flow distribution (liquid and vapor phases) were defined.

- Inlets and Outlets: The inlet stream consisted of an aqueous ethanol mixture with a specified initial concentration, while the outlet stream was set to produce concentrated ethanol and wastewater.

- Output Analysis: The purity of ethanol in the product and its recovery percentage were calculated and analyzed.

Azeotropic Distillation Column Modeling In this stage, a solvent is introduced into the column to break the water-ethanol azeotrope.

- Column Definition: The azeotropic column was configured with a larger number of trays compared to the pre-concentration column to ensure efficient phase contact.

- Solvent Introduction: The location and flow rate of the solvent entering the column were optimized to maximize separation.

- Performance Simulation: Simulation results included the ethanol purity in both the vapor and liquid phases at each tray, as well as the impact of solvent quantity on these purities.

Solvent Recovery Column Modeling

The primary objective of this section is to separate the solvent from water and recover it for reuse in the process.

- Column Definition: This column was configured with fewer trays and a lower operating temperature compared to the azeotropic column.

- Recovery Simulation: The percentage of solvent recovered and the energy consumption required for separation were the primary evaluation criteria.

Conclusion

This project has demonstrated that simulating the ethanol dehydration process using Aspen Plus can provide valuable insights into system behavior and facilitate the selection of optimal operating conditions for efficient separation. The use of benzene as an solvent yielded promising technical results. It is recommended that…

Related Projects

SANILCO Company has successfully executed numerous projects in the field of heterogeneous ethanol dehydration, including:

-

Improving Heterogeneous Ethanol Dehydration Simulation Using Data Regression in Aspen Plus

This project enhanced the simulation of heterogeneous ethanol dehydration by employing data regression to increase simulation accuracy and achieve optimal results in Aspen Plus. It involved analyzing and optimizing operational parameters. -

Simulating Ethanol Dehydration Process Using the UNIQUAC Model in Aspen Plus

After examining and simulating the ethanol dehydration process using the NRTL model, this project explored the process using the UNIQUAC thermodynamic model. By considering non-ideal interactions between mixture components, this model exhibits higher accuracy in predicting phase behavior and mixture separation, especially in more complex conditions. -

Simulation and Optimization of Ethanol Separation from Water in Aspen Plus

In this research, the heterogeneous ethanol dehydration process was simulated and optimized using Aspen Plus with the aim of generalizing it to an industrial unit. The primary objective was to reduce operational costs and increase energy efficiency while considering the actual conditions of the industrial unit. -

Dynamic Simulation of Heterogeneous Ethanol Dehydration Process with Aspen Plus

This project described the dynamic simulation of the heterogeneous ethanol dehydration process using Aspen Plus Dynamics. The report aimed to analyze the dynamic behavior of the process and optimize operating conditions and control systems.

Simulation of Heterogeneous Ethanol Dehydration Process with Aspen Plus

In this project, the simulation of the heterogeneous ethanol dehydration process was carried out using Aspen Plus versions 10 and 12 based on the methods and data from the article. Operational parameters were analyzed and optimized.