Introduction

In this project, computational fluid dynamics (CFD) is employed to simulate the behavior of carbon dioxide gas during the absorption process using two different absorption models: amine solution absorption and alumina nanoparticle absorption. A brief definition of CFD is provided below.

Assumptions:

- Gas flow is assumed to be steady-state.

- The model implemented for the primary modeling (alumina nanoparticles) follows Knudsen diffusion equations.

- The process operates under isothermal conditions.

- The membrane pores and cavities are uniform, and their density is constant across the entire membrane surface.

- Fick’s law is used to model the diffusion and permeation of carbon dioxide through the membrane.

- The behavior of the gas mixture entering the membrane module is assumed to be ideal.

- For the comparative model using alumina nanoparticle solution, the gas entering the membrane consists of only carbon dioxide.

- The operating conditions in both systems are dry in the primary modeling.

- Gas flow is laminar.

- For the alumina nanoparticle absorption modeling, membrane characteristics are obtained from experimental data in the reference article.

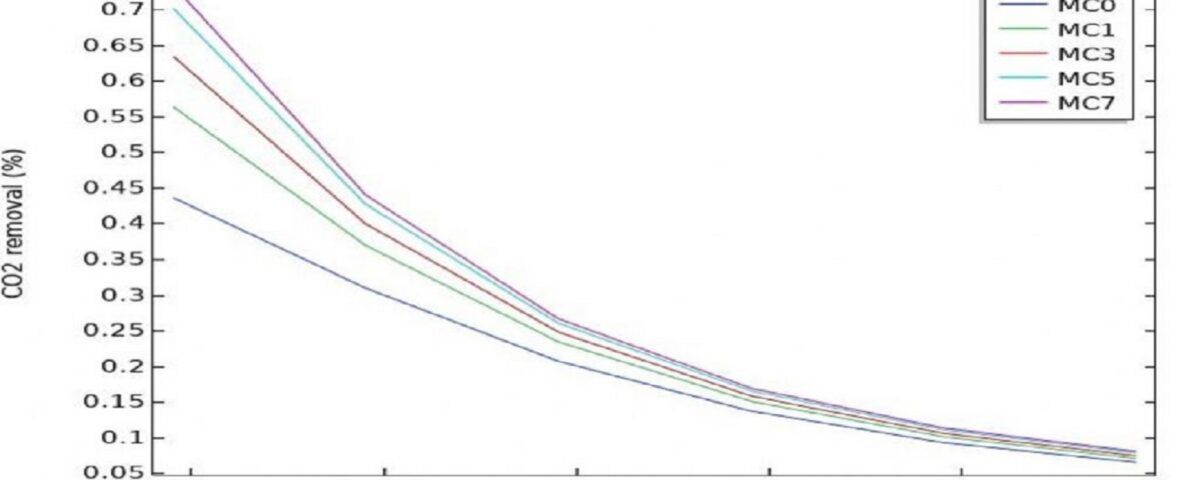

Modeling with Alumina Nanoparticle Solvent

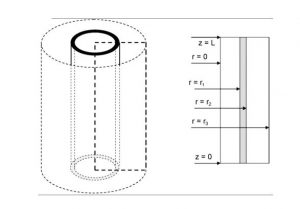

In this project (see figure below), a 2D model is developed for separating carbon dioxide from the gas stream using an alumina nanoparticle solvent in a hollow fiber membrane contactor. Axial and radial diffusion within the shell, shell section, and membrane are considered.

The membrane contactor consists of three parts: shell, membrane, and shell. A CO2 gas stream flows (inside the shell), while the solvent flows in the opposite direction inside the shell. The steady-state two-dimensional mass conservation equation is written for all three parts. The gas stream enters the shell at z = L, while the solvent enters the shell at z = 0.

Carbon dioxide is separated as a result of diffusion through the membrane and subsequent absorption reaction with the solvent. The model is developed for a section of the hollow fiber, as shown in the figure above, where the solvent flow is fully developed with a parabolic velocity profile. The fibers are surrounded by a laminar gas flow in the direction opposite to the liquid flow, The figure below shows the cross-section of the membrane contactor.

Modeling of CO2 Absorption Using Alumina Nanoparticles with Comsol

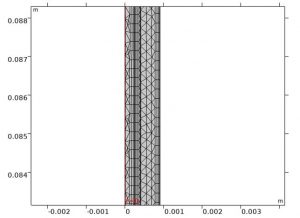

In this project, CO2 absorption process is modeled with the help of aluminum oxide nanofluid in Comsol software. The figure below shows the meshed module schematic for modeling and simulating the module.

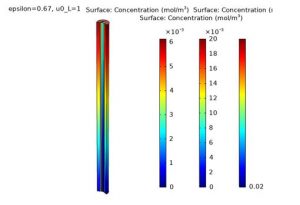

Contours of CO2 Concentration Distribution, from Right to Left: Shell, Membrane, Tube

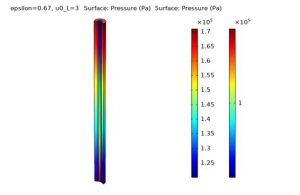

Contour of Pressure Changes Along the Membrane on Both Sides of the Shell and Tube

It should be noted that the main source of modeling is the following article:

Preparation and characterization of PVDF-filled MWCNT hollow fiber mixed matrix membranes for gas absorption by Al2O3 nanofluid absorbent via gas–liquid membrane contactor

This project has a complete report.