Introduction

The capture of carbon dioxide (CO2) from industrial flue gases has gained significant importance due to its detrimental effects on the environment. One effective method for CO2 separation is the use of solvent-impregnated membranes. In this process, a membrane impregnated with a specific solvent acts as a selective barrier, allowing the selective passage of CO2 molecules.

Advantages of Solvent-Impregnated Membranes

- High selectivity: Solvent-impregnated membranes can selectively separate CO2 molecules from gas mixtures.

- Low energy consumption: Compared to traditional methods such as chemical absorption, this process consumes less energy.

- Ability to operate at low temperature and pressure: This method can be operated at low temperatures and pressures.

- Modular design: Membrane units are designed modularly, allowing for easy capacity expansion

This MATLAB-based project, comprising approximately 450 lines of specialized code, was developed based on the following article and The project has been extensively analyzed under various conditions. The code can accommodate a wide range of feedstock specifications.

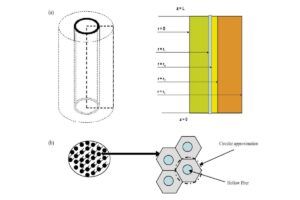

The attached schematic provides a simplified overview of the project. A hollow fiber membrane capable of compatibility with various solutions is employed. A range of solutions can be tested, including amine solutions and ionic liquids. Kinetic models and assumed parameters can be adjusted.

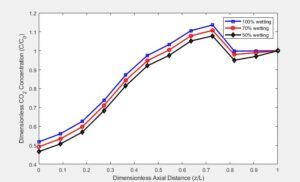

Various results have been obtained from this modeling, which in a specific case of carbon dioxide concentration inside the membrane is shown below.

Conclusion

Solvent-impregnated membranes are a promising technology for CO2 separation. Given the advantages of this method and recent advancements in this field, it is expected that we will witness a wider application of this technology in various industries in the future.