Introduction

Biogas, as a renewable and sustainable energy source, has increasingly gained attention in industrial and agricultural communities. This biofuel is primarily produced from the fermentation of organic and biological materials and consists of gases such as methane, carbon dioxide, and trace amounts of other gases. Given the rising demand for clean energy and the need to reduce environmental impacts associated with fossil fuels, optimizing biogas utilization has become one of the significant challenges.

Biogas reforming is a key process in converting this fuel into hydrogen, methane, and other valuable products. One effective method in this regard is the use of Pressure Swing Adsorption (PSA) technology. This method is introduced as a suitable solution due to its high capability in separating hydrogen from other gases, particularly in reforming processes. Additionally, combustion units play a crucial role in optimizing energy consumption and reducing pollutants. These units can achieve better performance in energy production when using reformed biogas while simultaneously minimizing negative environmental impacts.

Process Description

Biogas reforming using Pressure Swing Adsorption (PSA) and combustion units is an advanced process aimed at optimizing the quality of biogas and converting it into energy or hydrogen. This process includes several key stages, which are detailed below:

Biogas Production

Biogas is typically produced from the anaerobic decomposition of organic materials such as animal manure, agricultural waste, and other organic matter. This process is facilitated by microorganisms and generally yields methane (CH₄) and carbon dioxide (CO₂) as the main products.

Biogas Purification Using PSA

a) Principles of PSA Operation

Adsorption

The produced biogas is fed into a PSA unit. At this stage, the gas passes through an adsorbent bed, which typically consists of zeolites or activated carbon. These materials selectively adsorb carbon dioxide and other impurities while retaining methane as the output gas.

Desorption

In the next stage, the pressure in the adsorbent bed is reduced. This action causes the release of the adsorbed gases and their recovery. During this phase, carbon dioxide and other impurities are removed from the bed, resulting in the production of purified methane.

b) Advantages of PSA

Increased Methane Purity: The use of PSA enhances the purity of methane to over 90%.

Reduced Energy Costs: This process generally requires less energy compared to other purification methods.

High Recovery Rate: PSA can optimize methane recovery and prevent its loss.

Combustion Unit

a) Operation of The Combustion Unit

Combustion of Purified Gas: The purified biogas (rich in methane) is fed into the combustion unit. At this stage, the gas is burned to produce thermal energy. This energy can be used directly for heating or converted into electricity.

Electricity and Heat Generation: The energy obtained from combustion can be converted into electricity through turbines or generators. Additionally, the heat produced from combustion can be utilized for industrial applications or residential heating.

b) Advantages of Biogas Combustion

Reduction of Pollutants: Burning biogas instead of fossil fuels can help reduce greenhouse gas emissions and air pollutants.

Utilization of Renewable Resources: This process contributes to the use of sustainable and renewable energy sources.

Waste Management: By converting organic waste into energy, this process also aids in waste management.

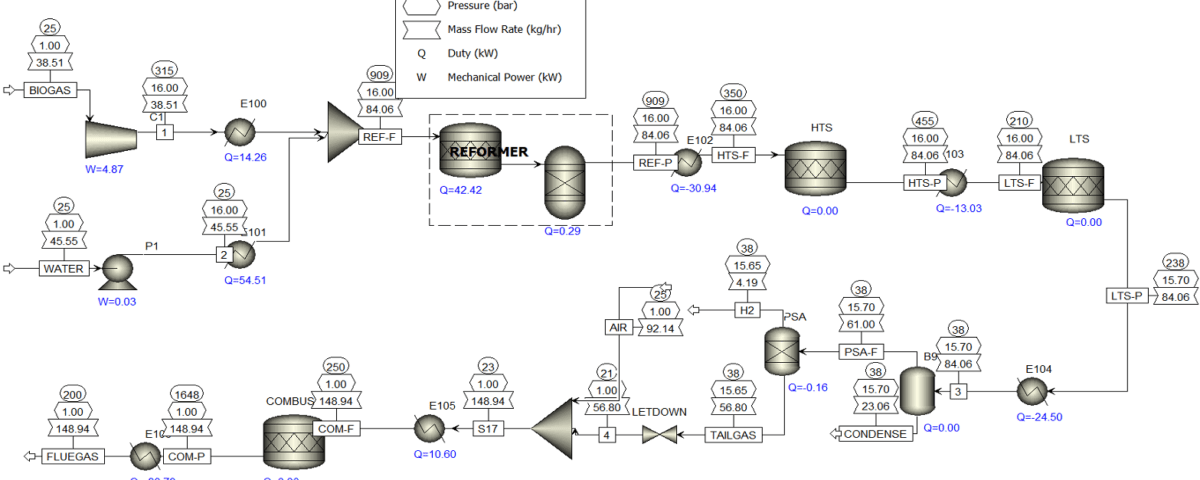

Process Simulation

Simulating the biogas reforming process using Pressure Swing Adsorption (PSA) and the combustion unit is a powerful tool for better understanding and optimizing this complex process, conducted with Aspen Plus. This simulation can assist engineers in predicting system performance, identifying strengths and weaknesses, and developing improvement strategies. Below are the various stages and aspects of simulating this process in detail.

Definition of The Process and Objectives of Simulation

The simulation of the biogas reforming process is typically aimed at:

Performance Analysis: Assessing the system’s performance under various conditions.

Design Optimization: Identifying optimal dimensions for the PSA and combustion units.

Energy Production Forecasting: Evaluating the potential energy production from purified biogas.

Cost Reduction: Identifying and minimizing operational and capital costs.

Modeling System Components

a) Biogas Modeling

Chemical Composition: Determining the ratios of methane, carbon dioxide, hydrogen, and other components present.

Physical Properties: Establishing the density, vapor pressure, and other physical characteristics of biogas.

b) PSA Unit Modeling

Adsorption: Utilizing adsorption models such as Langmuir or Freundlich to describe adsorption behavior and temperature effects.

Temperature and Pressure Model: Defining operational conditions (pressure and temperature) and their impact on adsorption efficiency.

Pressure Cycle Model: Simulating the various stages of the pressure swing cycle (high pressure, low pressure, and recovery phase).

c) Combustion Unit Modeling

Combustion Model: Applying combustion models, such as kinetic models, to describe the gas burning process.

Energy Calculation: Evaluating the amount of energy produced from combustion based on gas composition and operational conditions.

Pollutant Emission: Simulating the production levels of greenhouse gases and pollutants such as NOx and CO.

Results Analysis

After conducting the simulation, the results must be carefully analyzed:

PSA Efficiency: Evaluating the purity and recovery rate of methane.

Combustion Performance: Assessing the efficiency of the combustion process and energy production.

Pollutant Emission: Examining environmental impacts and the levels of pollutant emissions.

Optimization and Development

Following the analysis of the results, optimization of the system can be undertaken:

Parameter Adjustment: Modifying operational parameters such as temperature and pressure to enhance performance.

Redesign: Implementing changes in the design of the PSA and combustion units to increase efficiency.

Cost Management: Identifying methods to reduce operational and capital costs.

Examples of Completed Projects

Simulation of the Hydrogen Production Line with Reforming of Methane with Aspen Plus and Hysys

Simulating and Optimizing of The Reforming and Methanol Unit of FANAVARAN Pet. Co. With Aspen Plus

Simulation of Hydrogen Separation in PSA Tower with Aspen Adsim

Simulation of TEHRAN Refinery PSA Process: Hydrogen Purification With ADSIM

Conclusion

The biogas reforming process using PSA and combustion units is an effective solution for enhancing the quality of biogas and generating energy from renewable sources. This process not only aids in reducing pollutants and greenhouse gases but also leads to the production of clean and sustainable energy. Given the economic and environmental benefits, this technology can play a significant role in the future of energy supply.

Simulating the biogas reforming process with PSA and combustion units serves as a valuable tool for understanding and optimizing renewable energy processes. This simulation, carried out in Aspen Plus software, can assist engineers and researchers in designing more efficient and sustainable systems, thereby improving the overall performance of energy production processes from biogas. Considering the growing importance of renewable energy, such simulations can play a crucial role in the future of energy supply.