Introduction

The BANDAR ABBAS Refinery is one of the most significant and largest industrial projects in the oil and gas sector of Iran, located in Hormozgan Province near Bandar Abbas, with a daily crude oil processing capacity of 300,000 barrels. This refinery began operations in 1998 and plays a crucial role in supplying fuel and petroleum products for the nation. Given its strategic geographical position next to the Persian Gulf, which allows easy access to open waters and commercial ports, the refinery has become a key hub for the export and import of petroleum products.

The BANDAR ABBAS Refinery pursues several objectives, including meeting domestic needs for refined products and fossil fuels.

Additionally, in light of environmental requirements and international standards, the BANDAR ABBAS Refinery is keenly focused on optimizing production processes and reducing emissions. Innovative technologies, along with the implementation of advanced monitoring and control systems, enable the refinery to maintain product quality while minimizing negative environmental impacts.

Simulation and Optimization in the Refinery Industry

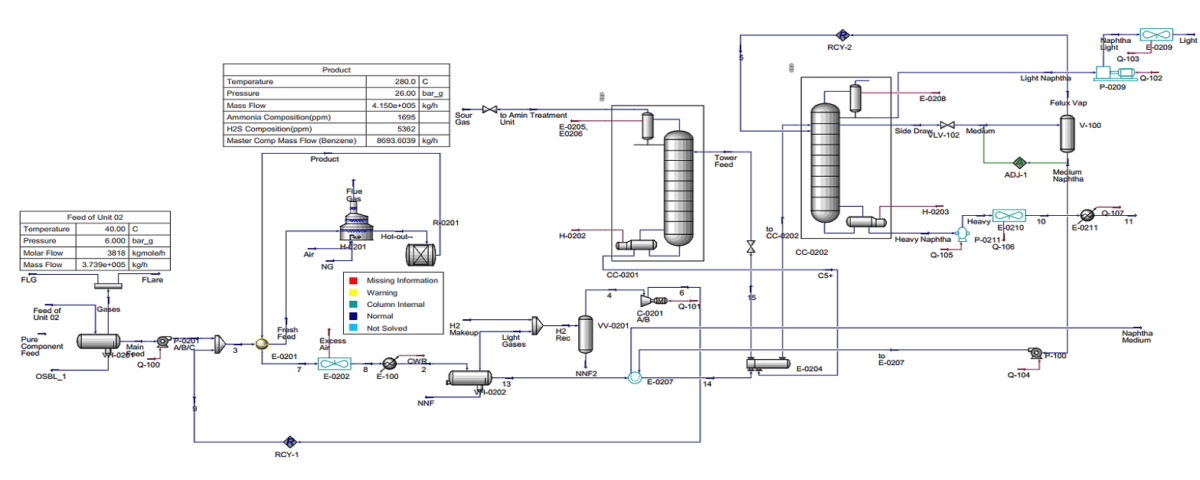

Simulation and optimization serve as key tools in the refining industry to fine-tune production processes effectively. As one of the largest refining complexes in Iran, the Bandar Abbas Refinery seeks advanced technologies such as Aspen HYSYS to enhance benzene recovery. This process simulation software allows for the design, analysis, and optimization of processes in a graphical environment, enabling engineering teams to pay closer attention to process details and identify optimal points. By utilizing this tool, various aspects such as costs, production time, and product yield can be improved, ultimately leading to greater efficiency in benzene production.

Process Flow Analysis

Simulating the benzene process at the Bandar Abbas Refinery using Aspen HYSYS aids in the precise analysis of material flows at both microscopic and macroscopic levels. This tool enables analysts to conduct multi-stage simulations and examine different system behaviors under various operational conditions. By carefully considering parameters such as temperature, pressure, and feed composition, weaknesses and strengths within the process can be identified. In other words, these simulations assist engineers in optimizing the production process and reducing unnecessary time or costs through a thorough understanding of system dynamics.

Production Efficiency Optimization

Optimizing benzene production at the Bandar Abbas Refinery may involve enhancing operational methods and reducing costs. Engineers can simulate various scenarios using Aspen HYSYS to identify the best operational combinations, including optimizing temperature and pressure in reactors, adjusting feed ratios, and selecting appropriate catalysts. This process not only increases productivity but also helps reduce waste and byproducts. By providing suitable solutions to improve the quality of produced benzene, the Bandar Abbas Refinery will be capable of meeting domestic needs and strengthening its position in international markets.

Risk Assessment and Sensitivity Analysis

A vital aspect of optimizing benzene recovery is risk assessment and sensitivity analysis. Using Aspen HYSYS, the effects of changes in key parameters on overall process performance can easily be simulated. This includes synergy analysis and the use of Monte Carlo methods to forecast the impact of fluctuations in raw material prices or changes in market conditions. Project managers can make better decisions regarding financing, raw material procurement, and production planning based on this information. Consequently, these techniques help identify, analyze, and manage project-related risks.

Environmental Impact and Sustainability

By utilizing simulation and optimization in the benzene recovery process at the Bandar Abbas Refinery, the environmental impacts of these processes can also be minimized. Aspen HYSYS enables engineers to assess the operational effects on sustainability and pollution levels. Process optimization can reduce the production of harmful gases and waste materials, ultimately contributing to sustainability and environmental preservation. Commitment to environmental standards and improving performance in this area not only enhances the reputation of the Bandar Abbas Refinery among consumers and the community but also aids in the sustainable development of the country’s refining industry.

Process Overview

The simulation and optimization process for benzene recovery at the Bandar Abbas Refinery using Aspen HYSYS involves several key stages. Initially, the system modeling begins with simulating the input and output flows of benzene, defining material specifications, operational conditions, and process settings. Once these inputs are defined, the simulation can analyze the system’s behavior under various conditions.

Subsequently, using optimization algorithms in Aspen HYSYS, different parameters such as temperature, pressure, and flow rates are analyzed to attain maximum benzene recovery under optimal economic and safety conditions. This includes sensitivity analysis to identify key parameters and establish optimal performance points for the system. Additionally, the simulation can continue to identify and reduce waste and improve energy efficiency. Ultimately, the conclusions drawn from these analyses can enhance the design and operation of the benzene production unit, achieving the economic and environmental goals of the Bandar Abbas Refinery.

Conclusion

In conclusion, the simulation and optimization of benzene assessment at the Bandar Abbas Refinery using Aspen HYSYS offers an opportunity to improve economic performance and enhance competitiveness. Through precise analyses, risk assessments, and continuous optimization, the Bandar Abbas Refinery can be recognized as a successful model in Iran’s refinery industry and the region. These efforts not only contribute to increased profitability and improved energy efficiency but also lay the groundwork for innovation and future advancements in this industry. In light of increasing competition in global markets, focusing on process optimization and utilizing modern technologies is an indispensable necessity for achieving sustainable success.

To enhance the performance and efficiency of the benzene assessment unit at the Bandar Abbas Refinery, ANILCO has conducted comprehensive simulation and optimization studies on the key equipment and processes of this unit. These studies include:

– Pre-feasibility and benzene recovery at the Persian Gulf Star Oil Refinery using Comfar.

– Simulation and optimization of benzene recovery at the Persian Gulf Star Refinery using Aspen HYSYS.

– Optimization of the CCR unit at the Persian Gulf Refinery through innovative conceptual design.

Simulation and Optimization of Benzene Recovery at Persian Gulf Star Refinery Using Aspen HYSYS

In this project, the simulation and optimization of benzene recovery at the Persian Gulf Star Refinery have been simulated using Aspen HYSYS version 14.