Description

A dehydration unit, or dryer, is an industrial facility designed to remove excess water or moisture from various substances. Imagine squeezing a wet sponge to remove water; a dehydration unit performs a similar function but on an industrial scale with a variety of materials. This process is crucial in many industries as the presence of water in substances can lead to issues like equipment corrosion, reduced product quality, and even explosion hazards.

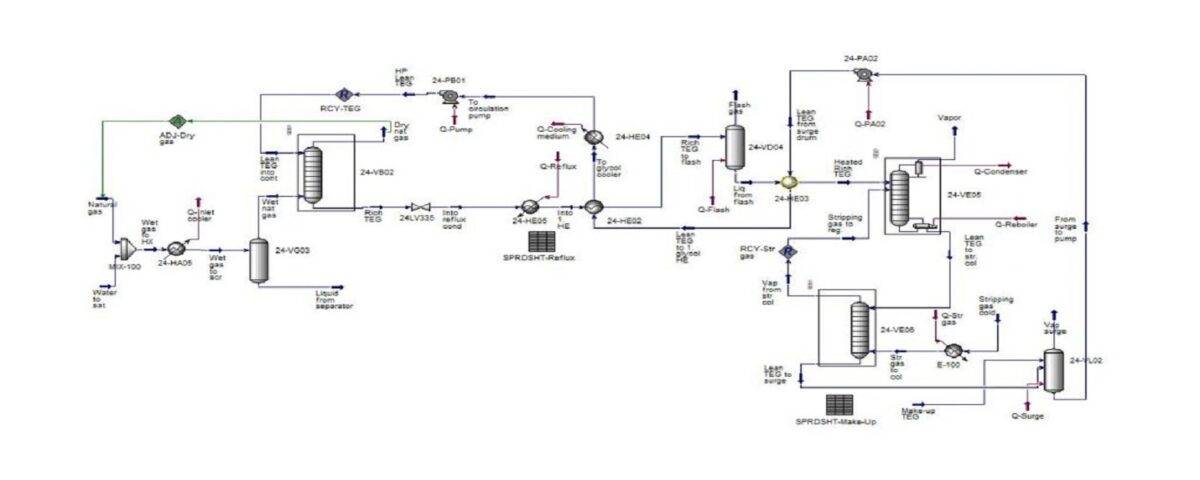

Dehydration units employ a range of techniques such as distillation, adsorption, ion exchange, and more to separate water from materials. For instance, in the petroleum industry, natural gas is dehydrated to prevent pipeline corrosion. In the pharmaceutical industry, raw materials for drugs are dried to maintain their quality. In essence, dehydration units play a pivotal role in producing high-quality and safe products

Dehydration Units

this unit usually in gas processing units, according to the quality of the gas output from the gas field or the gas with crude oil, the processes required for refining and producing various products such as light gas (natural gas), ethane, liquefied gas (LPG), gas liquids (NGL) and condensate will be different. Many of the country’s gas fields are considered sweet due to the low amount of sulfur compounds. For this purpose, there will be no need to sweeten natural gas and remove acid gases (H2S and CO2). Therefore, by extracting gas and separating heavy compounds (gas liquids), two processes of adjusting the dew point of light gas and stabilizing gas condensates are performed.

In this project, the simulation of dehydration unit, natural gas is done with the help of Aspen Hysys software from the following article.