Description

Acetone is the simplest ketone and one of the most abundant volatile organic compounds in the atmosphere. This material is used in the production of cosmetics, household and personal care products.

Acetone is one of the most widely used organic solvents in industry. About a third of the total purchase of acetone in the world is used as a solvent, and a quarter of the purchase of acetone in the world is used for the production of cyanohydrin acetone and methyl methacrylate.

Acetone is a very good solvent for many plastics and some synthetic fibers and natural resins. and is used to thin polyester resin, clean tools, and dissolve two-part epoxies and cyanide crystals before they harden. Acetone is also used as one of the volatile substances of paints and varnishes on wood. Also, acetone, as one of the main cleaning materials, has taken a big role in preparing metals before paint. Acetone can also be used as an anti-rust for metals.

Acetone Production Process

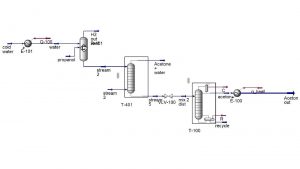

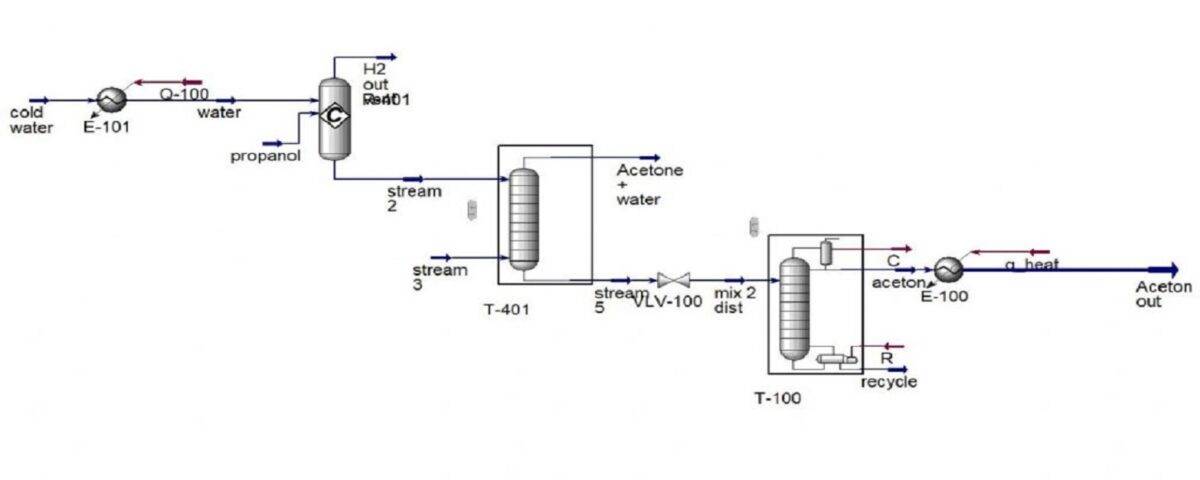

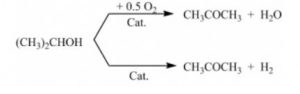

There are many methods to produce this substance, in this project the process of producing acetone by dehydrogenation of isopropyl alcohol is simulated. Isopropyl alcohol and water have been used as input feed. The reaction is carried out in a reactor in the presence of a catalyst, and finally, after separating the products, acetone is obtained. Using Aspen HYSYS software, the simulation of the above process has been done and efforts have been made to improve the amount of acetone output.

In 1970, for example, in the United States of America, about 50-60% of the total production of acetone was from isopropanol. At the global level, Cumene process with the acetone product is in the first place in the production of this substance. Like formaldehyde and acetaldehyde from related alcohols, for isopropanol, oxidative dehydrogenation at a temperature of 400-600 °C on Ag or Cu catalyst, as well as a pure dehydrogenation process at a temperature of 300-400 °C on ZnO or at a temperature of 500 °C and a pressure of 3 Loading on Cu or brass catalysts is possible. The superior method is dehydrogenation. This method is performed in the gas phase, for example with ZnO according to the process of Standard Oil Company, with about 98% isopropanol reactivity and 90% selectivity to acetone.

Simulation of Acetone Production Process

In this project, the simulation of acetone production process by dehydrogenation of isopropyl alcohol has been done in Aspen Hysys software. Isopropyl alcohol and water have been used as input feed. The reaction was carried out in a reactor in the presence of a catalyst. And finally, after separating the products, high purity acetone is obtained.