Description

Lubricating oils are obtained from the heavy oil cuts obtained from the distillation tower in the vacuum of the refinery (lube cut) as feed. To produce lubricating oil, the aromatics in the feed must be separated by solvent until the permissible limit is reached. Lube cut are composed of many complex compounds, therefore, to describe such processes, complex compounds are considered as polynomials. and simulate the process using thermodynamic models. Liquid-liquid extraction method is used to separate aromatics from lube cut in RDC extraction tower. In this article, based on the research study conducted on the results of the research presented in the field of simulating the process of extracting aromatics from lube cut, the mentioned process has been investigated.

Extraction of Aromatics From Lube Cuts

Aromatic compounds have a low viscosity index and their presence in oils reduces the quality of the oil. Separation of aromatics from oil should be done by solvent extraction method. Among the solvents used to extract aromatic substances from oils are: Furfural, phenol, sulfur anhydride, N-methyl pyrrolidine and duosol. As the amount of solvent increases in the process, the amount of refined material decreases but its quality improves.

For the extraction of aromatics, furfural is usually used as a solvent, which has relatively suitable properties. The aromatics extraction unit consists of a tray or column equipped with a stirrer and a rotating plate. Feed and solvent are introduced from both sides of the column and are mixed together. The temperature gradient from the top to the bottom of the extraction column is 30 to 50 °C, and the temperature at the top of the column is about 140 °C.

After separating the two aromatic phases and the oil from the same phase, the oil is sent to the extraction column for re-purification. Finally, after complete cleaning, it enters the solvent separation section. In this part, furfural is separated from the products by dissolution in water and distillation and returned to the cycle. Refined oil also enters the dewaxing section of the refinery.

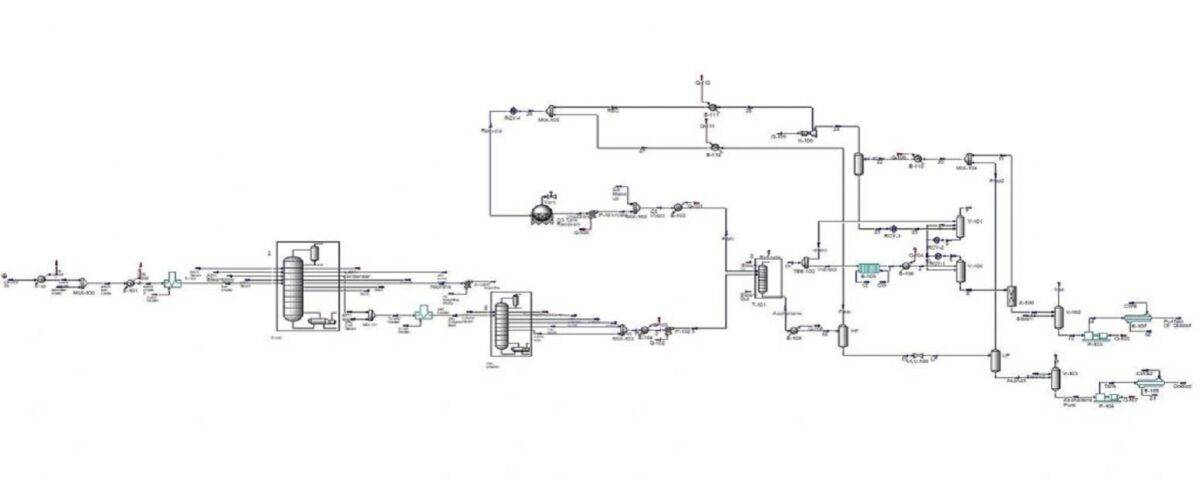

Aspen Hysys Simulation Extraction of Aromatics From Lube Cut

In this project, the aromatics extraction unit from lube cut is simulated in Aspen Hysys software. The extraction unit consists of a column with a tray or equipped with a rotary plate stirrer (RDC). The feed and solvent enter from the two ends of the column and move in the opposite direction and contact is established in this way. Solvent-to-feed ratio and column temperature are dependent on the type of oil and the desired viscosity index. The figure below shows the process PFD.