Introduction

This project focuses on simulating an innovative ammonia recovery system from digested liquid in wastewater treatment plants (WWTP) and its simultaneous use with biomethane in a solid oxide fuel cell (SOFC). Given the urgent need for industries to enhance energy sustainability and reduce greenhouse gas emissions, simulating this process can play a significant role in the development of new technologies. Aspen Plus software was utilized as the primary tool for process modeling in this project.

Process Description

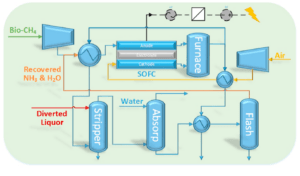

In this project, an innovative system is designed for recovering ammonia from digested liquid in WWTPs while simultaneously utilizing it with biomethane in an SOFC. The ammonia recovery process consists of several key stages that are systematically designed to optimize the recovery and use of this energy source.

Main Process Sections

1. Air Stripping Column:

In this section, ammonia is separated from the digested liquid using the exhaust gas from the fuel cell. This column includes multiple stages to enhance separation efficiency and minimize energy requirements. The resulting gas, containing ammonia, is then transferred to the absorption unit.

2. Absorption Column:

In this column, the ammonia-laden gas contacts a countercurrent water flow, allowing ammonia to dissolve in the water. This step is designed for the purification of ammonia and its preparation for use in the SOFC.

3. Flash Drum:

The effluent stream from the absorption column enters the flash drum, where a portion of the mixture is converted to vapor to achieve the appropriate steam-to-carbon (s/c) molar ratio for internal reactions in the SOFC.

This process has been comprehensively modeled to allow for precise optimization and analysis, enabling an assessment of its impact on energy efficiency and greenhouse gas emissions reduction at wastewater treatment plants.

Simulation Description

The simulation of this process was conducted using Aspen Plus software based on the work of Grasham and colleagues. The key stages of the simulation are as follows:

– Thermodynamic Model Selection:

The NRTL-RK thermodynamic method was used to simulate phase equilibria and chemical reactions, which is suitable for processes involving polar and non-polar mixtures.

– Modeling of Process Units:

RStoic and RGibbs reactors were utilized to simulate chemical reactions and gas equilibria in the fuel cell. These reactors modeled the conversion of methane to hydrogen, the water-gas reaction, and hydrogen oxidation.

The Air Stripping Column (RADFRAC) was modeled for ammonia separation from digested liquid using 30 stages without a condenser or reboiler.

The Flash Drum (Flash2) was simulated to separate liquid-vapor mixtures and improve the steam-to-carbon molar ratio in the process.

– Operating Conditions and Assumptions:

The simulation was conducted under specific temperature and pressure conditions, assuming ambient conditions of 1 bar and 23 degrees Celsius. The composition of the input air to the process was assumed to be a ratio of 79:21 nitrogen to oxygen.

Results and Analysis

The simulation results indicate that the proposed system is capable of recovering significant amounts of nitrogen in the form of ammonia from the digested liquid. Utilizing this system alongside the solid oxide fuel cell (SOFC) results in a substantial increase in renewable electricity generation and a reduction in energy consumption at wastewater treatment plants. Analyses suggest that employing this technology could have positive effects on reducing greenhouse gas emissions, thereby enhancing environmental performance.

Simulation of Ammonia Recovery Process and Its Use in Solid Oxide Fuel Cells (SOFC) with Aspen Plus

In this project, the simulation of the ammonia recovery process and its use in a solid oxide fuel cell (SOFC) with Aspen Plus software has been investigated. This project is educational.