Introduction

Digital simulations, especially in software like REVIT, play a crucial role in optimizing and designing industrial systems. These technologies enable engineers and designers to create precise and functional models, significantly enhancing the efficiency and sustainability of projects. Among the key areas for these simulations are systems such as PHWB, sand filtration, industrial dryers, and absorption chillers. Each of these components plays a vital role in various industries, and simulating them in REVIT helps reduce costs, increase efficiency, and optimize energy consumption. This project focuses on an in-depth analysis of these systems’ simulation in REVIT and their importance in improving the quality and performance of industrial projects.

PHWB Simulation

The PHWB system is an essential component for pH control in industrial water and wastewater systems, tasked with adjusting and controlling the water’s pH level. Simulating the PHWB device in REVIT allows for precise analysis of this system under varying operational conditions.

In this simulation, factors such as temperature, pressure, and water chemistry are examined. REVIT software enables these parameters to be adjusted to yield accurate results for system performance under real-world conditions. This modeling allows engineers and industrial designers to observe how minor operational changes impact pH control.

Since PHWB devices are used to reduce energy consumption and improve efficiency in water treatment systems, simulating them in REVIT enables companies to optimize performance while reducing operational costs.

Sand Filtration Process Simulation

Sand filtration is a highly effective method for removing suspended particles and impurities from water. In REVIT, the sand filtration system can be modeled in detail. This simulation aids engineers in adjusting key aspects such as physical dimensions, layer depth, and other important parameters to observe each factor’s impact on system efficiency.

The process includes analyzing water flow rate and retention time in filtration layers. Simulating sand filtration in REVIT enables performance analysis under various input water conditions and flow fluctuations. With these insights, designers can optimize filtration systems and lower operational costs. Furthermore, the simulation allows designers to assess the effects of using different materials in the filter structure, such as sand, activated carbon, and other layers.

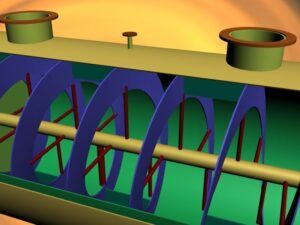

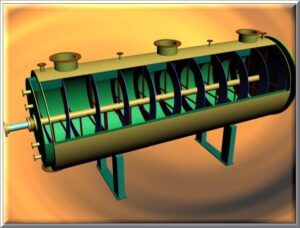

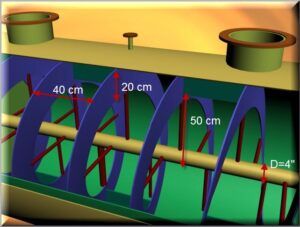

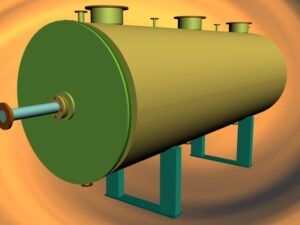

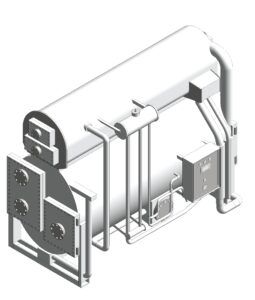

Industrial Dryer Simulation

Industrial dryers are crucial equipment used to reduce moisture in materials during industrial processes. Simulating these systems in REVIT enables three-dimensional design analysis and adjustment of critical parameters like temperature, drying time, and airflow type.

For industrial dryer simulations, highly detailed 3D models are created to adapt to specific materials and environmental conditions. These analyses allow engineers to achieve energy efficiency and reduce production costs.

This type of simulation is particularly valuable for industrial designs in sectors like food, pharmaceuticals, and chemicals. Accurate simulation of the drying process enhances performance and reduces energy loss. Additionally, studying how the device performs under varying conditions helps prevent technical issues during production.

Absorption Chiller Simulation

Absorption chillers play an essential role in HVAC systems and industrial cooling, using absorption and refrigeration processes to cool environments. Simulating absorption chillers in REVIT provides engineers with a precise tool to test performance under various conditions and create optimized designs.

With REVIT, chiller dimensions and system parameters—such as refrigerant type, operating conditions, and heat exchange—can be closely examined. The simulation also enables engineers to assess energy efficiency and environmental impact of the chiller system.

Simulating absorption chillers in REVIT also assists in identifying design weaknesses and analyzing energy consumption, allowing designers to provide cost-effective and sustainable cooling systems for industrial and building projects.

Conclusion

Simulating industrial systems in REVIT offers designers and engineers enhanced control and effective optimization, which is particularly valuable in areas such as pH control, sand filtration, industrial dryers, and absorption chillers. These processes not only increase efficiency and reduce operational costs but also significantly contribute to environmental sustainability and energy savings. Overall, simulating industrial systems in REVIT not only improves project design and execution but also enables higher performance standards and the creation of more sustainable systems.

Industrial Equipment Design (Revit)

If you’re looking for precise, professional simulations in REVIT, we’re here to execute your projects to the highest standards, tailored to your needs.