Introduction

Oil extraction from carbonate reservoirs is associated with numerous challenges. The most significant ones include flow path blockages due to deposits and a reduction in permeability. These deposits, which often consist of solid particles, calcite, dolomite, or organic matter from petroleum products, accumulate near the wellbore. Such issues reduce reservoir efficiency and lower oil production rates. Acidizing is one of the most effective well stimulation methods, restoring permeability and enhancing production. By injecting acid and allowing it to react with obstructive deposits, flow paths are cleared, and the medium’s permeability increases. With rising energy demand and declining conventional reserves, optimizing extraction processes from carbonate reservoirs has become critical. Advanced techniques, such as precise modeling and simulation with tools like COMSOL Multiphysics, offer significant potential in this field by enabling detailed analysis of chemical and physical processes in porous media.

In this study, three acidizing flow patterns were examined: wormholes, uniform dissolution, and surface dissolution. Previous studies indicate that the acid injection rate plays a vital role in forming these patterns. Different injection rates can directly impact reservoir permeability and performance. This project aims to simulate the dissolution processes in formations using precise modeling. The results can help improve the design and performance of acidizing operations in carbonate reservoirs, enhancing the method’s efficiency.

Methodology and Modeling

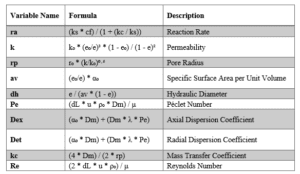

In this project, continuum modeling was chosen as the primary approach for simulating the acidizing process. This method is preferred for its high accuracy in analyzing chemical and physical processes in porous media. The modeling involves a set of physical equations describing fluid flow, mass transport, and structural changes in the porous medium.

Simulating Flow Using Darcy’s Equation

To model fluid flow in the porous medium, Darcy’s equation was applied, which relates flow velocity to permeability, fluid viscosity, and the pressure gradient.

In this study, permeability and pressure gradients were calculated using real data and numerical simulations. Results showed that reduced permeability in specific regions increases the pressure gradient, which is clearly illustrated in the two-dimensional pressure and velocity maps.

Mass Transport and Chemical Reactions

To analyze the diffusion and chemical reaction of acid in the porous medium, the mass transport equation was used. This equation describes the impact of advection, diffusion, and chemical reactions on acid concentration. Using this model, acid concentration distribution over time and reservoir depth was simulated. Simulations revealed that acid concentration is highest near the reservoir’s inlet and decreases as it penetrates deeper.

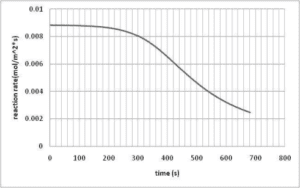

Porosity and Permeability Changes During Acid Reactions

Chemical reactions between acid and reservoir rock induce structural changes in the porous medium, including variations in porosity and permeability. These changes were mathematically modeled, and the results demonstrated that reaction rates and acid flow velocity have a direct impact on these changes. For instance, low acid injection rates increase permeability near the inlet, whereas high rates lead to uneven patterns.

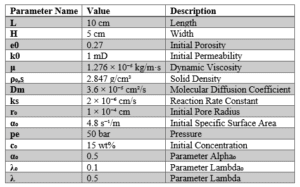

The following fixed and variable parameters were used in the simulation and are detailed in corresponding tables:

- Initial Permeability: The medium’s inherent ability to allow fluid flow.

- Initial Porosity: The percentage of void space in the formation.

- Acid Concentration: The initial acid concentration in the injected solution.

- Injection Rate: The flow rate of acid entering the reservoir.

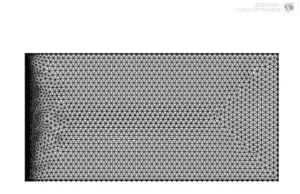

Modeling Tools and Configurations

The modeling was conducted using COMSOL Multiphysics versions 4.4 and 5.4. This software enables simultaneous resolution of complex differential equations through the finite element method (FEM). For improved simulation accuracy, fine meshing and precise solver settings were employed. The results modeled structural changes in the porous medium and analyzed the impact of acid injection rates on flow patterns.

Results and Analysis

Dissolution Patterns in the Acidizing Process

Simulation results indicated that the type of dissolution pattern depends on the acid injection rate. Three primary patterns were identified:

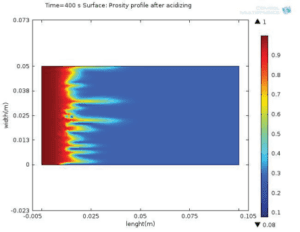

Surface Dissolution

At low injection rates, acid penetration is limited to the formation’s surface. Here, chemical reactions occur near the surface, creating uniform structural changes in the porous rock. Simulations showed that this pattern increases permeability near the wellbore but limits acid penetration depth. For example, in one simulation, permeability near the inlet increased by more than 30%, while deeper changes were minimal.

Wormholes

At optimal injection rates, acid penetrates the formation through branch-like paths called wormholes. These structures result from a balance between chemical reactions and diffusion in the porous formation and lead to significant permeability improvements. Wormholes enhance acidizing efficiency by creating deep, controlled penetration while minimizing acid consumption. Simulations and experimental data showed that wormholes form best at an injection rate of approximately 5 mL/min. Additionally, wormhole depth analysis confirmed permeability increases of up to 200% in this pattern.

Uniform Dissolution

At high injection rates, acid flows so rapidly that chemical reactions cannot fully occur. Consequently, a significant portion of the acid bypasses the formation without meaningful interaction, leading to limited permeability changes. In this case, only 10–15% of the formation volume was affected, while most of the acid was wasted.

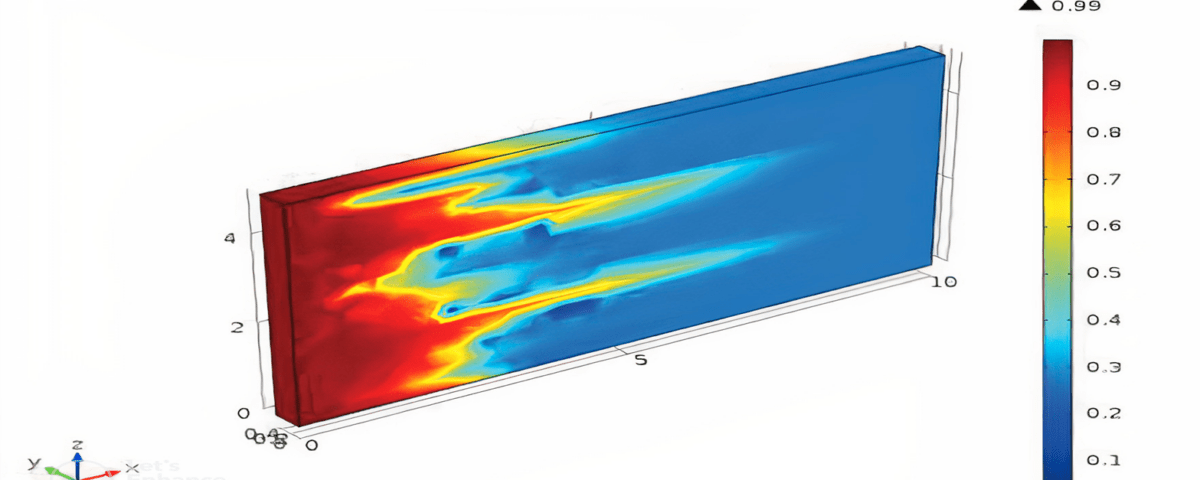

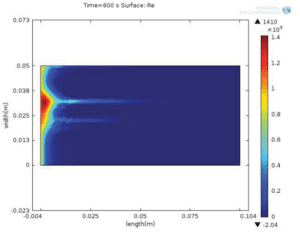

Pressure and Velocity Distribution in Porous Media

A key outcome of this project was the precise simulation of pressure and velocity distribution in porous media. These simulations:

- Showed sharp pressure gradients near regions with reduced permeability.

- Identified fluid flow paths, aiding in locating high-resistance areas.

To better visualize these results:

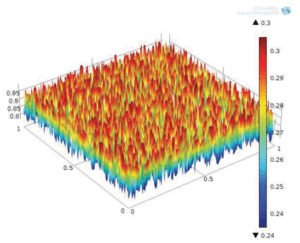

- Pressure and velocity maps were plotted for various cross-sections of the medium.

- Changes in flow velocity and pressure were presented as 2D and 3D graphs, demonstrating flow behavior under different conditions.

Impact of Physical and Chemical Parameters

Changes in permeability, porosity, and fluid viscosity significantly affected system behavior. For instance, increased fluid viscosity reduced the Peclet number and altered flow paths.

Comparison with Experimental Data

Simulation results were compared with experimental data, showing high accuracy in predicting real-world behavior. For example, the simulated wormhole depth and permeability increase closely matched experimental observations.

Conclusion

This study comprehensively analyzed acidizing flow and chemical reaction patterns using detailed simulations. The findings demonstrate the critical role of optimal injection rates in maximizing process efficiency, minimizing acid consumption, and enhancing permeability. The simulations effectively analyzed complex behaviors in porous media using COMSOL Multiphysics, providing insights to improve acidizing design and operations in carbonate reservoirs.

Acidizing Process Simulation in Carbonate Reservoirs with COMSOL

This project investigated carbonate reservoir acidizing using detailed modeling in COMSOL Multiphysics versions 4.4 and 5.4. The results highlight the significance of acid injection rates in forming dissolution patterns like wormholes and optimizing reservoir permeability.