Introduction

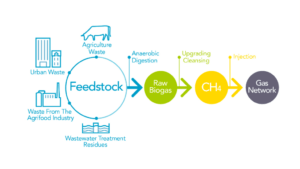

In recent years, attention to biomethane as a clean and renewable fuel has increased greatly. One of the main methods of biomethane production is biogas purification. Biogas is a mixture of gases, mainly methane (CH4) and carbon dioxide (CO2), produced by the decomposition of organic matter under anaerobic conditions. To produce biomethane, we separate carbon dioxide from biogas.

One of the effective technologies for gas separation is pressure swing adsorption (PSA). This method has attracted the attention of many researchers due to its lower energy consumption than other methods. In the PSA process, we use solid adsorbents such as activated carbon that have the ability to absorb gases. By changing the pressure, we separate the absorbed gases from the absorbent surface and produce pure gas (in this case, methane).

In this research, we have used activated carbon derived from pine sawdust for biogas purification and biomethane production using PSA process. The main goal of this research is to develop a numerical model to predict the performance of the PSA process and optimize the operating conditions.

Description of the Process

In the PSA process, we place a tank containing a solid adsorbent (activated carbon) under high and low pressure alternately , In the high pressure stage, we contact the gases in the feed stream (biogas) with the adsorbent, and CO2 molecules are absorbed more than CH4 on the surface of the adsorbent. In the low pressure stage, we have separated the adsorbed gases from the adsorbent surface and produced an output gas rich in CH4. Below are the steps of a PSA cycle:

Absorption: We introduce the gas mixture under high pressure into the absorbent bed. Adsorbable gases interact with the adsorbent and are absorbed on its surface. The gas that is less absorbed (product gas) is mainly removed from the bed.

Evacuation: We reduce the pressure inside the bed. The gases absorbed in the previous step are separated from the absorbent surface due to pressure reduction and removed from the system.

Flaking: We increase the pressure inside the bed again to prepare for the next absorption step. We usually do this step using a compressor.

Depressurization (in some systems): An inert gas (such as nitrogen) is introduced into the bed at low pressure to remove the remaining adsorbed gases from the bed.

Simulation of the PSA process

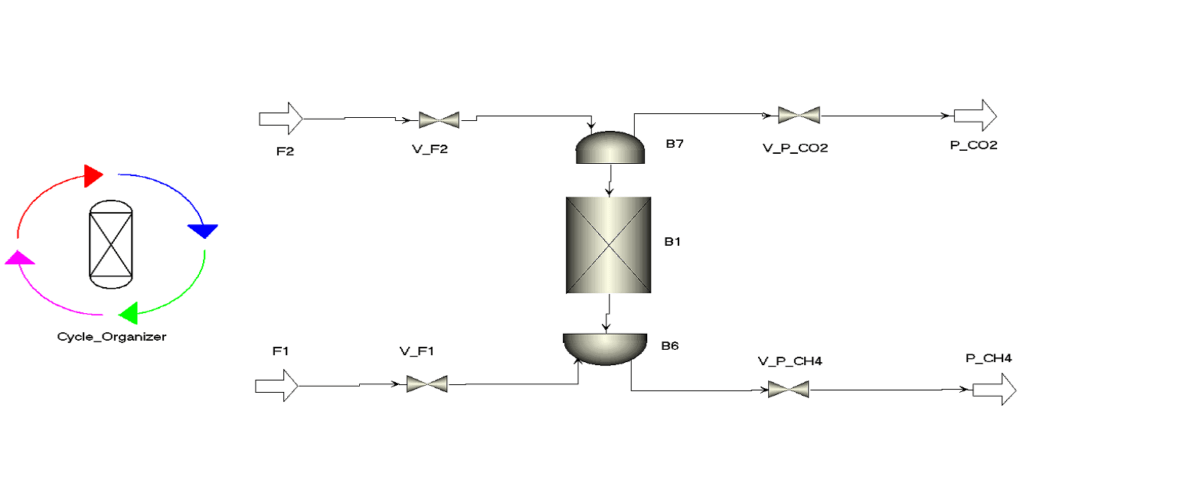

In this section, we will analyze the simulation of PSA (pressure swing surface adsorption) process for biogas purification using Aspen Adsorption software. This software is a powerful tool for modeling and simulating gas separation processes, which allows accurate analysis of system behavior and optimization of operating conditions.

System Modeling

At first, we define the system components including CO2, CH4 and He gases, activated carbon absorber and absorbent bed with specific dimensions. Then, we enter the initial conditions of the system such as pressure, temperature and the composition of the inlet gas into the software.

Equilibrium modeling and adsorption kinetics: We use Langmuir-Freundlich and IAST isotherm models to model adsorption equilibrium and LDF model to model adsorption kinetics.

Simulation of failure tests

We define laboratory conditions and simulate failure curves and then compare with experimental data.

PSA cycle simulation

We define a four-stage PSA cycle and evaluate its performance by calculating various parameters. Simulation parameters and results analysis: We use the first-order finite difference scheme for spatial discretization and compare the simulation results with experimental data.

Conclusion

In this research, with the aim of producing biomethane as a clean and renewable fuel, we investigated the process of pressure swing adsorption (PSA) to separate carbon dioxide from biogas. Using activated carbon derived from pine sawdust as adsorbent and Aspen Adsorption software for simulation, we were able to provide a detailed numerical model of this process. The simulation results showed that the PSA process using activated carbon can be used as an efficient method to produce biomethane with high purity. Also, by optimizing operational parameters such as pressure, temperature and flow rate, it is possible to improve process performance and reduce biomethane production costs. This research is considered an important step in the direction of developing clean energy production technologies and reducing dependence on fossil fuels.

PSA unit simulation: CO2 absorption from biogas in ADSIM software

Our company has simulated the PSA unit (pressure fluctuating surface adsorption) for CO2 separation from biogas in ADSIM software. This project is accompanied by training.