Introduction

The two-dimensional design of Process and Instrumentation Diagrams (P&ID) and Process Flow Diagrams (PFD) in AutoCAD software involves a comprehensive understanding of the engineering principles governing process design and the specific features of the software. P&IDs serve as precise representations of the piping and instrumentation within a process, illustrating the relationships and interactions between various components, such as valves, sensors, and equipment. These diagrams are essential for ensuring the effective implementation of safety, operational, and control measures in a plant.

On the other hand, PFDs provide an overview of process flows, focusing on key equipment and flow paths while also explaining energy and material balances. The software’s features, such as layer management, blocks, and annotations, facilitate effective communication among engineering teams and ensure clarity and compliance with project specifications. Mastery of these tools and concepts is crucial for producing accurate diagrams and data that assist in the design, implementation, and maintenance of industrial processes.

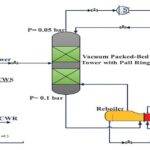

PFD and P&ID diagrams are prepared by Autocad software. Hysys software is a chemical process simulation software. which is mainly used for device sizing and is not used for preparing PFD and P&ID. SYMBOL All equipments are defined in the diagram called Symol & Legend according to standards such as IPS and are used to prepare PFD, P&ID. 2D design of all your units in AutoCAD completely with standards. Examples of these projects are shown below.

Process Description

Process description involves a detailed account of the main stages and activities related to transforming a raw material into a final product. This process typically includes various stages such as the arrival of raw materials, processing, quality control, and packaging. Each stage may involve operations like mixing, melting, refining, and more, all of which are influenced by different parameters such as temperature, pressure, and time.

Additionally, this description highlights the need for specific equipment such as reactors, heat exchangers, and control systems, whose design and optimization significantly impact the overall performance of the process. Furthermore, safety and environmental issues must be addressed at each stage to prevent pollution and potential hazards. Overall, the process description provides a conceptual overview of how raw materials are transformed into quality products, assisting managers and engineers in identifying operational trends and necessary optimizations.

Conclusion

In the realm of process design and analysis, particularly in the creation of P&ID and PFD diagrams, the emphasis lies on the importance of consistency and accuracy throughout all design stages. These processes not only aid in optimizing system performance but also ensure safety and compliance with industrial standards.

Ultimately, the ongoing enhancement of the skills of individuals and engineering teams in contemporary design and analysis fields is one of the key factors for success across various industries, leading to increased efficiency, reduced costs, and improved quality, not only in production but also in environmental conservation.

Specialized 2D P&ID and PFD Design in AutoCAD

In this project, specialized 2D P&ID and PFD design has been carried out using AutoCAD software.