Introduction

The South Pars Gas Complex, a major subsidiary of the National Iranian Gas Company, has been operating since 1998. It is responsible for the operation of the massive onshore gas facilities in the South Pars gas field. These facilities were designed and constructed by the Pars Oil and Gas Company.

Located in the cities of Asalouyeh and Kangan in Bushehr Province, the complex not only produces gas and its byproducts but also actively participates in corporate social responsibility initiatives, contributing to areas such as culture, education, health, employment, and environmental protection.

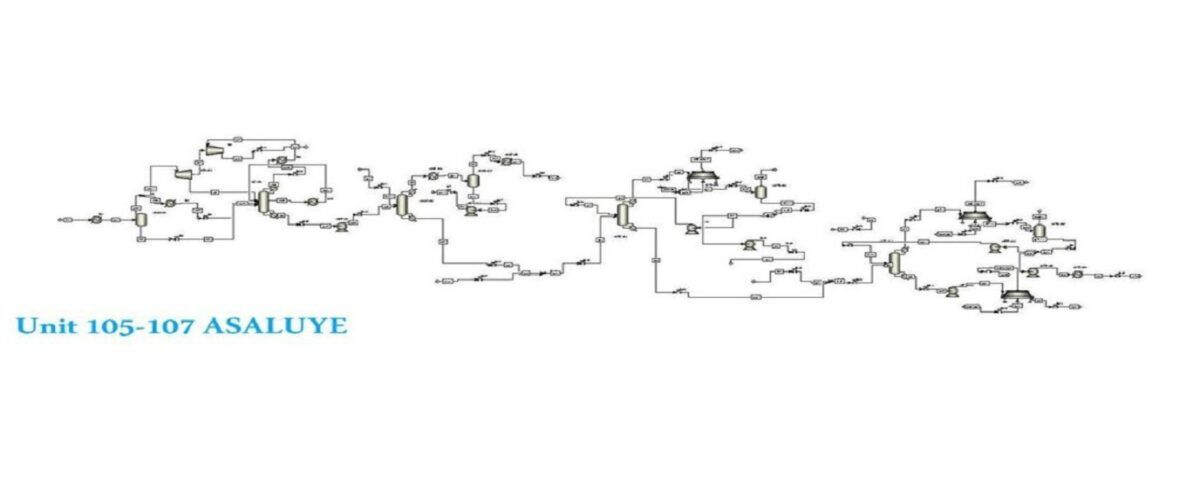

Units 105 and 107 of Asalouyeh are key units within the South Pars Gas Complex, playing a crucial role in the production of natural gas and its byproducts. These units employ advanced technologies to convert natural gas extracted from the South Pars field into valuable products.

Unit 105: Ethane Separation

Unit 105 primarily focuses on separating ethane (C2H6) from heavier hydrocarbons. Ethane serves as a feedstock for petrochemical plants to produce ethylene and polyethylene.

Ethane Separation Process in Unit 105

In Unit 105, natural gas enters a distillation column where, due to differences in boiling points, its components are separated. Ethane, being the lightest component, moves towards the top of the column and is then further purified using methods such as adsorption or additional distillation. To prevent moisture-related issues in subsequent stages, ethane is dried and then sent as feedstock to petrochemical units. The main equipment in this unit includes distillation columns, heat exchangers, pumps, compressors, and absorption towers.

Unit 107: Separation of Propane, Butane, and Heavier Hydrocarbons

Unit 107 is responsible for separating propane, butane, and heavier hydrocarbons (C5+). These products are used as fuel, petrochemical feedstock, and in various industrial applications.

In gas processing plants, Unit 107 plays a significant role in separating and purifying lighter and heavier hydrocarbons. The feed for this unit is a mixture of lighter hydrocarbons received from previous units like Unit 105. In Unit 107, using distillation columns, propane, butane, and heavier hydrocarbons (C5+) are separated and each is used as a final product or feedstock for subsequent units.

Propane and butane are primarily used as fuel and petrochemical feedstock, while heavier hydrocarbons are used in the production of petroleum and petrochemical products. This unit, equipped with advanced equipment such as distillation columns, heat exchangers, and pumps, performs the separation process with high accuracy and efficiency.

Dynamic simulation of units 105 and 107 of Asalouyeh with Aspen Plus

Dynamic simulation of units 105 and 107 of Asalouyeh in Aspen Plus software is a powerful tool for analyzing, designing, and optimizing these vital units in Iran’s gas industry. These simulations allow researchers and engineers to predict the behavior of these units under various operating conditions and potential disturbances, thus improving their performance.

The information of this project (dynamic simulation of units 105 and 107 of ASALOUYE with Aspen Plus) is available in the link below.

Static and Dynamic Simulation of 105, 106, 107 ASALOUYE with Aspen Plus

Conclusion

As discussed in detail in the previous topics, the dynamic simulation of units 105 and 107 of Assaluyeh in Aspen Plus software is a powerful and essential tool for better understanding, analyzing, and optimizing the gas separation processes in these units. By providing a virtual model of the unit, these simulations allow for examining the behavior of the system under different operating conditions and predicting its response to input changes.