Application of Artificial Intelligence in Chemical Engineering

مهر ۷, ۱۴۰۳

Miniaturized Membrane Reactors for CO2 Electroreduction

مهر ۷, ۱۴۰۳Introduction

Statistical mechanics and molecular simulation have maintained a long-standing and fruitful connection with chemical engineering since the 1950s, with early applications focused on dense matter. These simulations have provided a deeper understanding of the microscopic foundations of underlying processes and key topics of interest to chemical engineers, including phase equilibrium, fluid phase properties, and thermodynamics of mixtures.

Alongside these developments, computational approaches in chemical engineering have significantly advanced. The application of these methods is increasingly expanding, enabling chemical engineers to model, simulate, and solve complex problems more effectively. In turn, these principles have led to new innovations and advancements in various fields, including the development of new materials, more efficient manufacturing processes, and sustainable solutions to environmental issues.

Data-Driven Molecular Design and Simulation (DDMS) represents the most innovative approach in modern chemical engineering, leveraging the power of machine learning, artificial intelligence, and computational simulation methods to design and accurately predict the properties of new materials and optimize chemical processes. This transformative method offers significant advantages over traditional physics-based approaches, including rapidity, precision in property predictions, and flexibility in application to a wide range of materials and processes.

This approach not only accelerates the discovery process but also enhances the performance and sustainability of chemical products.

A Closer Look at Emerging Technologies Shaping the Field

1. Machine Learning and Artificial Intelligence for Predictive Modeling: Machine learning algorithms can predict properties such as solubility, reactivity, and toxicity based on molecular structures.

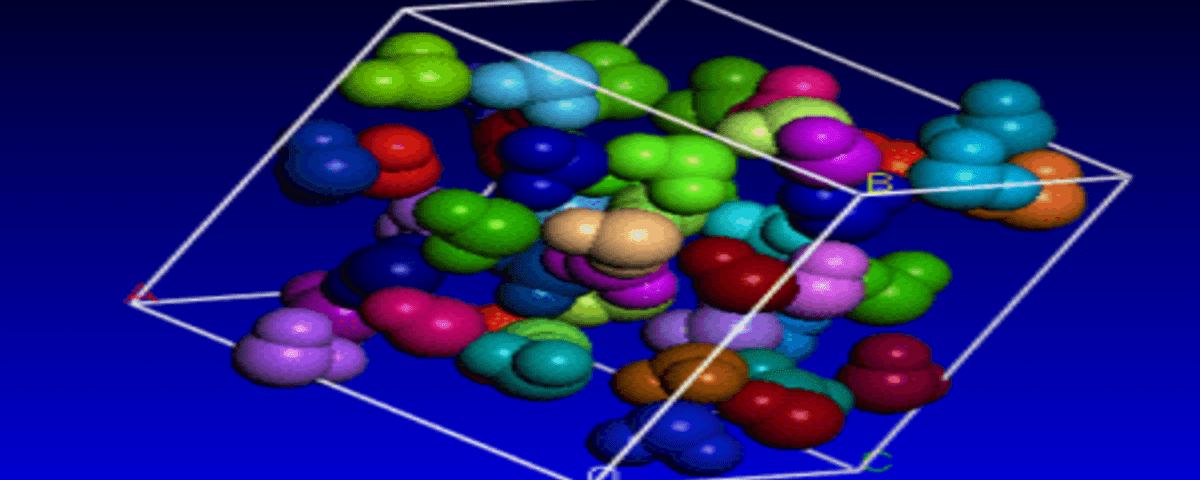

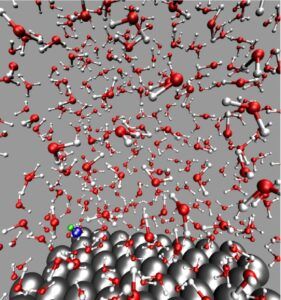

2. Molecular Dynamics Simulations (MD) for In-depth Molecular Behavior Analysis: These simulations provide comprehensive information about the movement and interactions of atoms and molecules over time.

3. Process Modeling and Optimization Simulations: Simulating chemical processes aids in optimizing conditions, scaling up from the lab to industry, and improving efficiencies.

Applications:

The scope of DDMS applications in chemical engineering is vast and includes:

– **Material Discovery**: DDMS serves as a powerful tool for discovering new materials with desired properties, such as pharmaceuticals, catalysts, and battery materials.

– **Nanomaterial Design**: DDMS provides a unique opportunity for designing new nanomaterials with specific properties, such as carbon nanotubes and quantum dots.

Advantages:

Notable advantages of DDMS compared to traditional methods include:

– Speed: Data-driven simulations operate significantly faster than traditional computational simulations, allowing for the examination of larger numbers of molecules and materials over shorter time frames.

– Accuracy: DDMS utilizes experimental data to train its models, resulting in more accurate predictions of material properties.

– Flexibility: Unlike traditional methods, DDMS can be applied to a wide range of materials and processes, including those that are challenging to model with other techniques.

Integration of Big Data and Machine Learning:

The integration of these technologies has transformed molecular design. By analyzing extensive datasets of properties and molecular behaviors, machine learning models can identify patterns and predict how new molecules will behave.

Techniques such as deep learning, neural networks, and support vector machines are particularly effective for managing complex, high-dimensional molecular systems.

These models can quickly screen millions of potential compounds, identify promising candidates for further study, and reduce reliance on trial-and-error testing.

Computational Chemistry and Molecular Simulation:

Advanced computational chemistry methods, including molecular dynamics (MD) and quantum mechanics/molecular mechanics (QM/MM), play a crucial role in simulating molecular behavior. For example, MD simulations allow researchers to study time-dependent molecular behavior and provide insights into their stability, reactivity, and interactions with other compounds. Conversely, QM/MM approaches offer a hybrid technique that combines quantum mechanical accuracy for electronic behavior with molecular mechanical efficiency for larger systems.

High-Throughput Screening and Virtual Libraries:

High-throughput screening (HTS) has been a game changer in molecular design. By using automated systems to rapidly test thousands of compounds, researchers can identify promising leads with desirable properties. Virtual libraries, containing digital representations of numerous potential molecules, are essential for HTS.

Sustainability and Green Chemistry:

By predicting the environmental impacts of new molecules, researchers can design products that are not only effective but also environmentally benign. This aligns with the principles of green chemistry, which emphasize the design of products and processes that minimize the use and generation of hazardous substances.

Collaborative Platforms and Open Science:

Online databases, shared computational tools, and collaborative networks enable researchers worldwide to share data, models, and findings. This collective approach accelerates innovation, reduces redundant efforts, and fosters a more inclusive scientific community.

Conclusion:

Data-Driven Molecular Design and Simulation (DD-MSS) emerges as an innovative approach in modern chemical engineering, utilizing the power of artificial intelligence and machine learning to predict and design molecular properties and material behavior. This transformative method has significant potential to accelerate the discovery and development of new materials and optimize existing processes. Ongoing advancements in computational techniques, coupled with robust data management and interdisciplinary collaboration, will lead to future developments and practical applications. DDMS stands as a transformative tool in chemical engineering, offering a new perspective for the development of new and advanced materials and processes. The integration of DDMS with traditional methods will bring remarkable innovations across various fields, including pharmaceuticals, materials science, and process engineering.

APIPCO is proud to introduce its experienced team specializing in the molecular simulation of processes related to modern chemical technologies.