GPS-X Wastewater Treatment Simulation Software

آذر ۱۷, ۱۴۰۳

SANILCO Industrial Process Company is a Leader in Industrial Simulation with a Commitment to Privacy

آذر ۱۹, ۱۴۰۳Introduction

IMSDesign is a cutting-edge engineering tool specifically designed for the design and simulation of reverse osmosis (RO) water and wastewater treatment systems. By providing detailed analyses and advanced features, this software has become an indispensable tool for optimizing treatment processes. As the demand for clean water and environmental protection grows, software like IMSDesign that can accurately simulate treatment system behavior is essential.

With its user-friendly interface and powerful data analysis capabilities, IMSDesign empowers engineers to design and simulate reverse osmosis (RO) systems with unprecedented accuracy. By offering in-depth analysis of water quality, dynamic system simulation, and energy optimization features, IMSDesign significantly reduces design time and costs, leading to more efficient treatment systems.

Developed by industry experts and environmental engineers, IMSDesign has emerged as a leading software solution for the design and simulation of reverse osmosis (RO) systems. In an era where clean water is a precious resource, software like IMSDesign plays a critical role in ensuring the optimal design and operation of water treatment facilities.

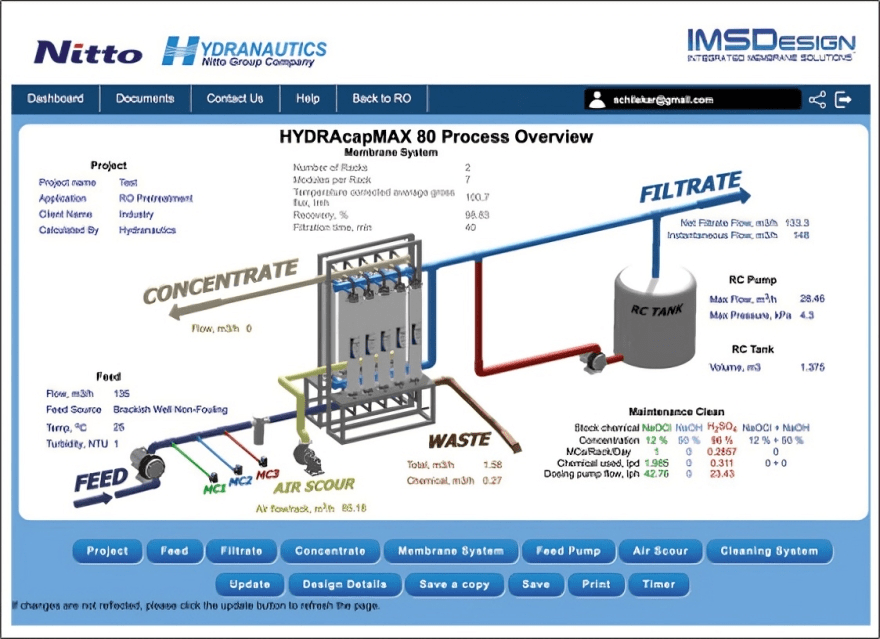

IMSDesign Software Environment

IMSDesign is a specialized software tool designed for the design and simulation of reverse osmosis (RO) water treatment systems. The software’s interface is designed to be user-friendly, making it accessible to both novice engineers and experienced professionals. This section will explore the user interface, components, and key features of IMSDesign.

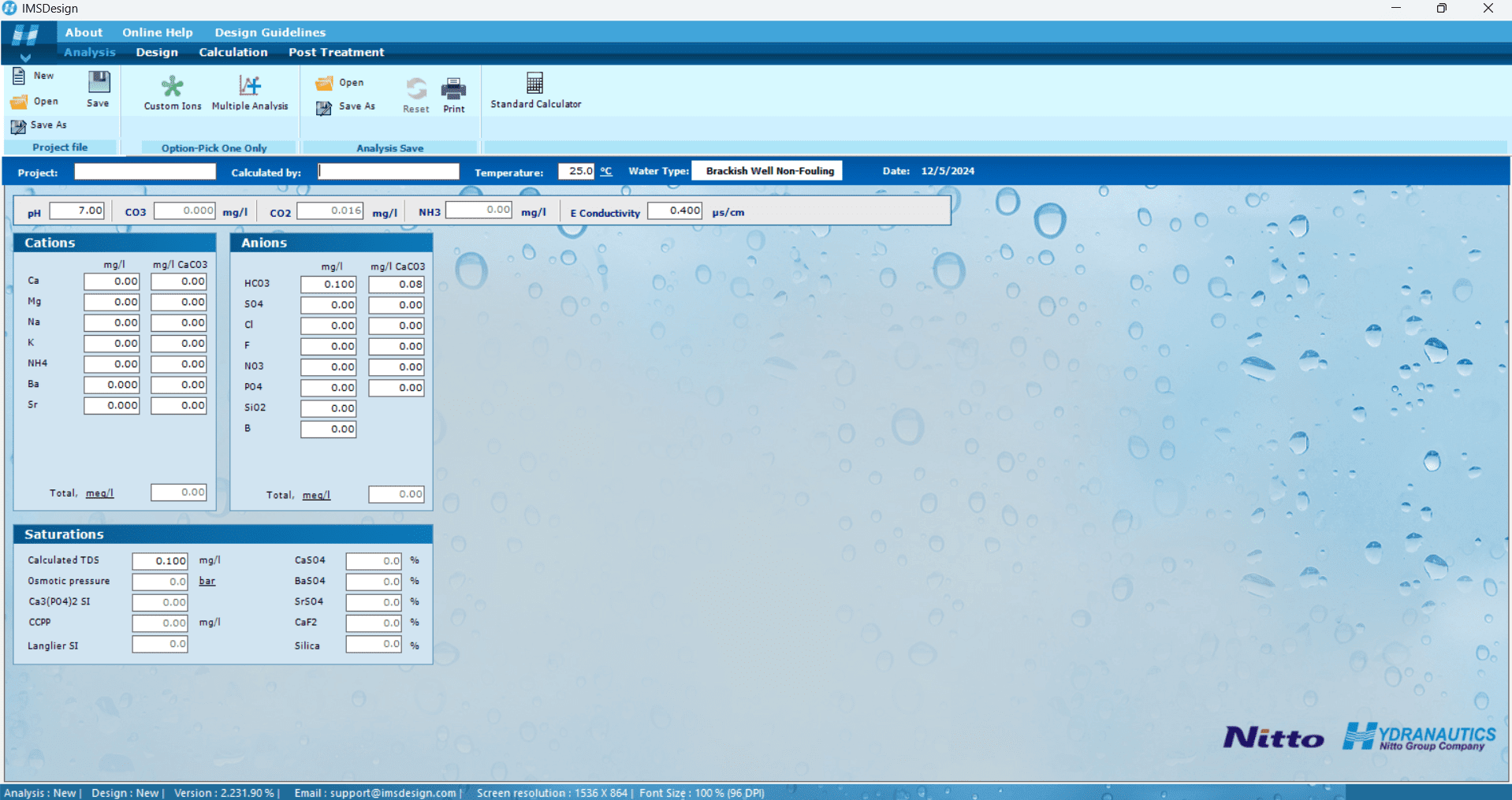

User Interface

The IMSDesign interface is simple and intuitive. The software is divided into several main sections, each designed for specific design and analysis tasks. Its modular structure allows users to follow the design process step-by-step.

Toolbar

Located at the top of the software window, the toolbar provides quick access to various functions, including:

- New Project: Creates a new design project.

- Open Project: Loads a previously saved project.

- Save Project: Saves the current project with all settings.

- Reports: Generates comprehensive reports of the design and analysis.

Main Workspace

The main workspace is where users can view and edit all design and simulation processes. It includes:

- System Diagram: A graphical representation of the system, showing components such as membranes, pumps, and pipes.

- Settings Panel: This is where users input parameters such as water flow rate, pressure, and feed water quality.

- Results View: Simulation results are displayed in the form of tables and graphs.

Design Steps in IMSDesign

1. Project Type Selection

The first step in using IMSDesign is to choose the project type. The software allows users to select from various project types, such as designing new systems or optimizing existing ones.

2. Inputting Feed Water Data

In this section, users input the quality of the feed water. This information includes:

- Temperature

- Salinity

- Ion concentrations (e.g., calcium, sodium, magnesium)

- Total Dissolved Solids (TDS) A tabular interface is provided for easy data entry and visualization.

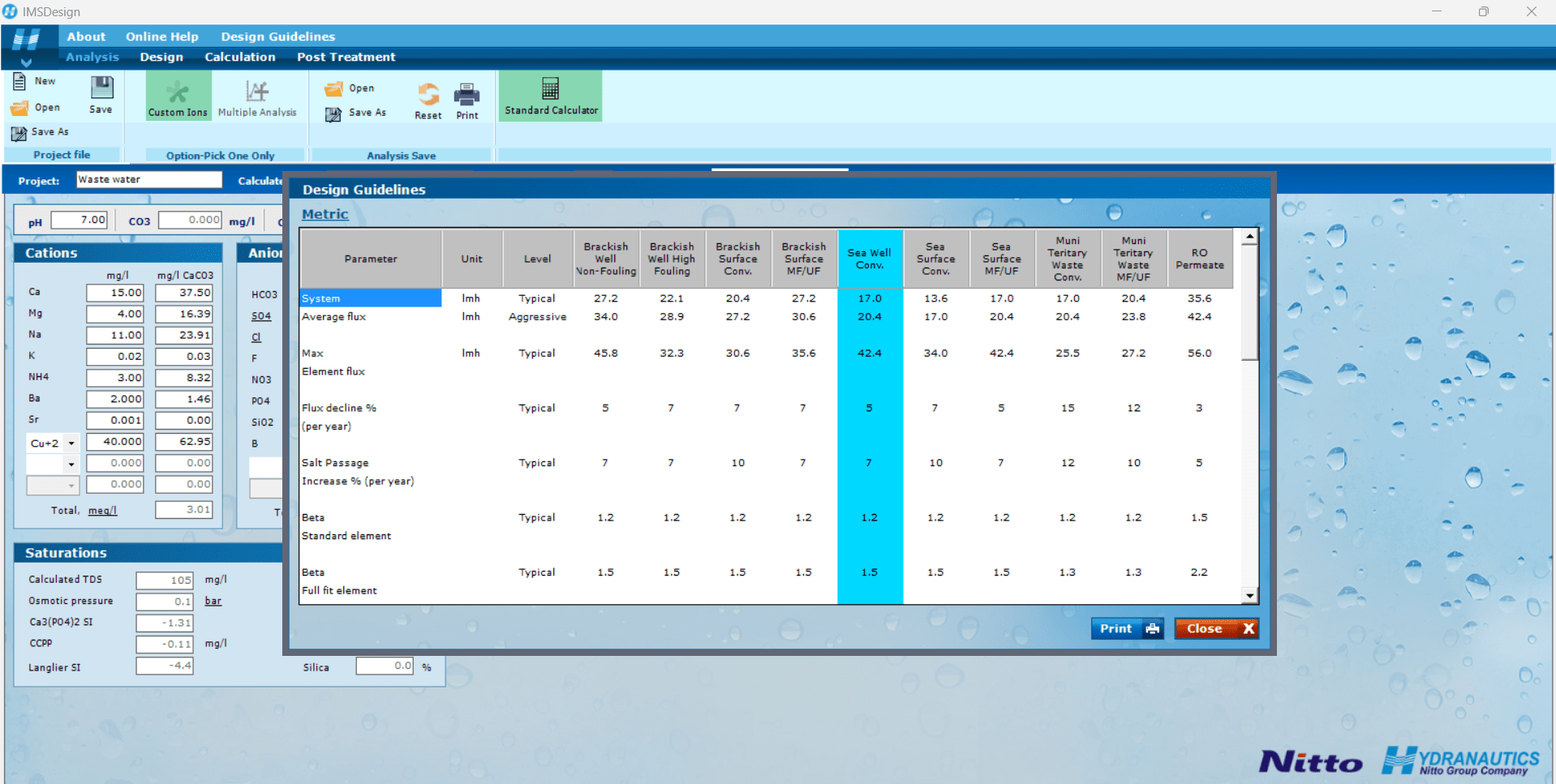

3. Membrane Selection

IMSDesign includes a database of commercially available membranes. Users can select the appropriate membrane based on their specific requirements. This section is highly interactive, providing detailed specifications of each membrane, such as size, capacity, and recovery rate.

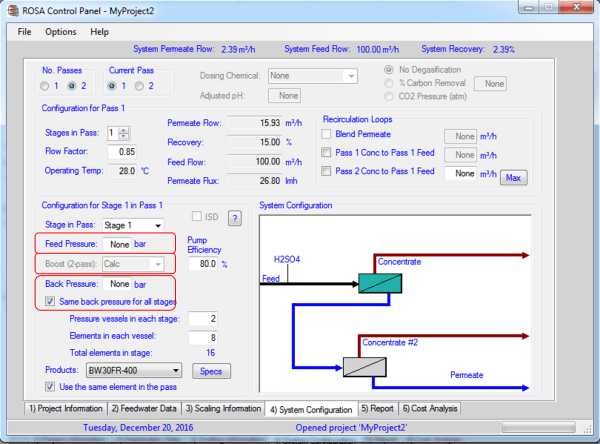

4. Setting Operating Parameters

In this stage, users can specify the operating parameters of the system:

- Operating pressure

- Flow rate

- Recovery rate

- Pressure drop limitations These settings can be adjusted using interactive sliders or by manually entering values.

5. Viewing Design Results

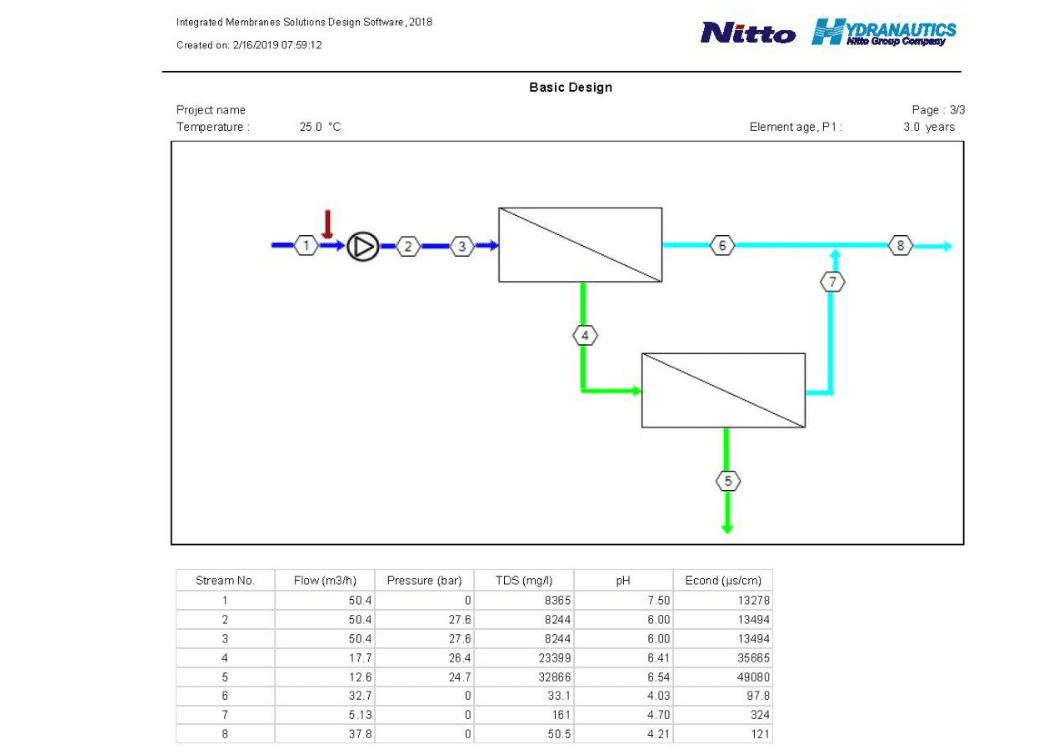

Once all the information has been entered, users can view the design results in tabular and graphical formats. These results include:

- Membrane performance (e.g., rejection and flux)

- Treated water quality

- System energy consumption

Reporting and Documentation

One of IMSDesign’s key features is its advanced reporting capabilities. Users can generate detailed reports on their designs and analyses. These reports encompass all input and output parameters, performance graphs, and optimization recommendations. Reports can be saved in various formats such as PDF and Excel.

Advanced Features of the IMSDesign Environment

- Multi-Array Simulation: IMSDesign enables the simulation of complex systems involving multiple arrays and membranes. This feature allows users to accurately design and analyze large-scale, multi-stage systems.

- Economic Analysis: Another significant feature of IMSDesign is its economic analysis capabilities. By calculating initial and operational costs, the software helps users select the most cost-effective option.

- Membrane Database: IMSDesign includes a comprehensive database of membrane types from various manufacturers. This database is regularly updated, and users can add new membranes to it.

- Long-Term Performance Simulation: This feature allows users to predict the long-term performance of a system. For example, it can simulate the decrease in membrane performance due to fouling and compaction.

- Training and Support: IMSDesign comes with interactive tutorials and training materials that help users quickly familiarize themselves with the software’s interface and capabilities. Additionally, the software’s support team is available to assist users with any issues.

Advantages and Disadvantages of the Software

Advantages:

- Optimized and Rapid Design: IMSDesign enables the accurate and rapid design and analysis of water treatment systems, making it invaluable for large-scale industrial projects.

- User-Friendly Interface: One reason for the software’s popularity is its simple and user-friendly interface, which reduces the need for extensive training.

- Accurate Simulation: The software can accurately simulate the reverse osmosis process, including changes in water quality and membrane performance.

- Support for Global Standards: IMSDesign is designed based on international standards, allowing its use in international projects.

- Advanced Reporting: Users can generate detailed reports on the performance of simulated systems and use them for in-depth analysis.

Disadvantages:

- Limitations in Specific Applications: While the software is well-suited for designing RO systems, it may require additional tools for applications involving other specific processes.

- High Cost: Using IMSDesign, especially advanced versions, can be expensive and may be challenging for small companies.

- Requires Specialized Knowledge: Despite the user-friendly interface, users need specialized knowledge in water treatment to fully utilize the software’s capabilities.

- Limited Language Support: Although the software supports major languages, users in some countries may encounter difficulties due to language limitations.

IMSDesign Simulation

Simulation within the IMSDesign software is one of its most useful features, allowing engineers and designers to analyze and evaluate reverse osmosis (RO) water treatment systems before implementation. This simulation encompasses various processes, including the selection of suitable membranes, analysis of operational parameters, and assessment of system performance under different conditions. The following sections delve into the steps involved in IMSDesign simulation and its applications.

Defining Simulation Objectives

Step 1: Inputting Initial Data

In this step, users must input the characteristics of the feed water into the system. This information includes:

- Total dissolved solids (TDS): The total amount of dissolved solids in the water.

- Temperature: The temperature of the feed water, which affects membrane performance.

- Ion concentration: Including cations and anions such as calcium, magnesium, sodium, sulfate, and chloride.

- Feed water flow rate: The amount of water entering the system. Input data is displayed in tables and graphs, allowing users to quickly make changes.

Step 2: Membrane Selection

IMSDesign provides a comprehensive database of various membranes. Users can select the appropriate membrane based on technical specifications and project requirements. These specifications include:

- Membrane type (UF, NF, or RO)

- Membrane size

- Recovery rate

- Operating pressure range

Step 3: Adjusting Operational Parameters

In this step, users must adjust the system’s operational parameters. These parameters include:

- Operating pressure: The pressure applied to force water through the membranes.

- Recovery rate: The percentage of water recovered as treated water from the total feed flow.

- Pressure drop: The pressure drop that occurs along the water flow path. IMSDesign simplifies the modification and examination of these parameters by providing graphical tools such as sliders and graphs.

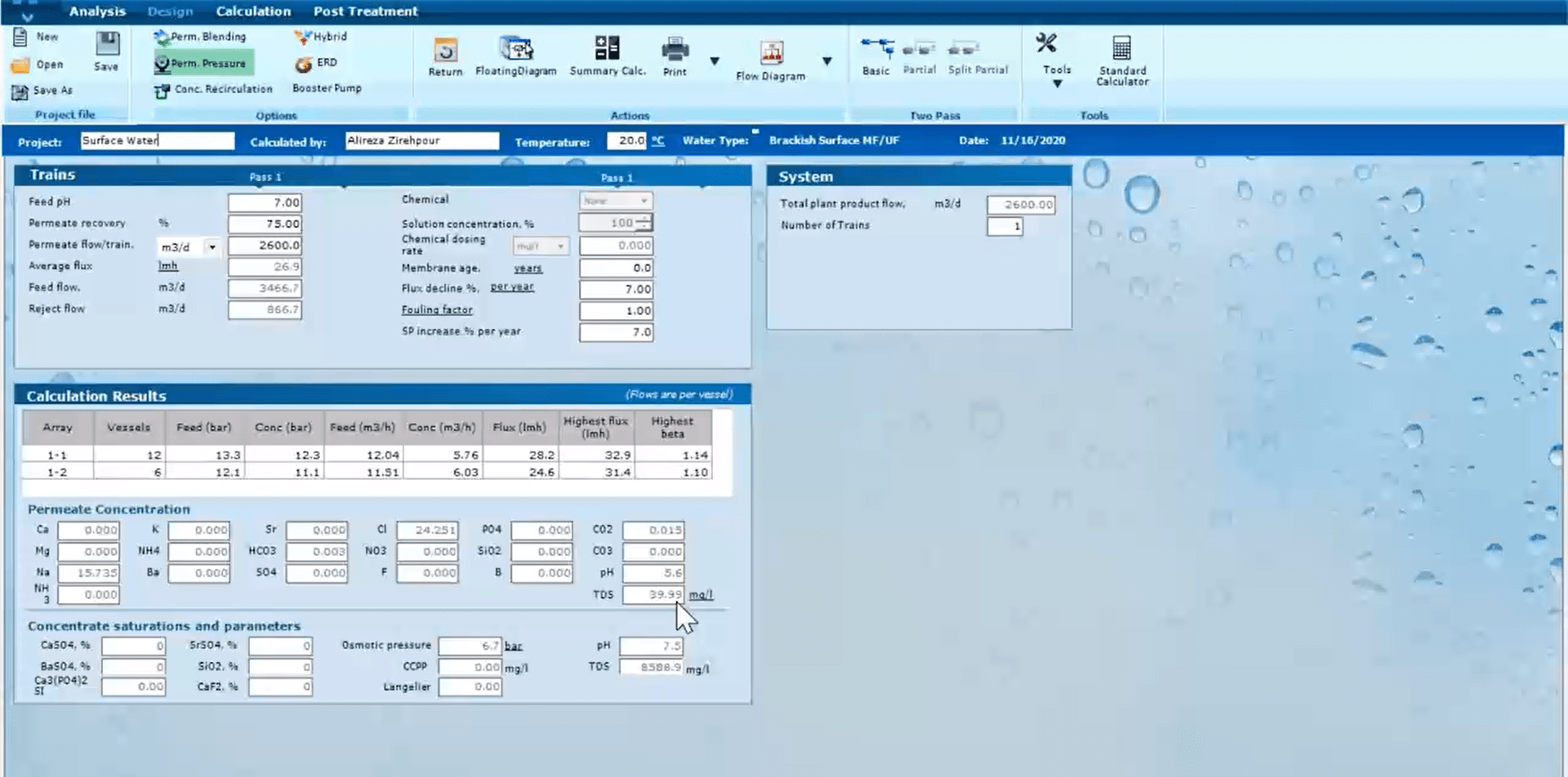

Step 4: Simulation and Results

After setting all parameters, users can run the simulation. The software displays the results graphically and numerically. These results include:

- Treated water quality: Including TDS, hardness, and other quality parameters.

- Membrane performance: Flow rate, rejection, and potential fouling.

- Energy consumption: Estimation of the energy required for system operation.

- Warnings: Identification of issues such as scaling or exceeding operational limits.

Step 5: Results Analysis

IMSDesign enables the analysis of simulation results. Users can modify input parameters to observe the impact of each on system performance and optimize their design.

Applications of Simulation in IMSDesign

1. Designing Industrial Water Desalination Systems

IMSDesign can accurately simulate systems used in desalination of brackish or seawater for industrial purposes.

2. Reducing Energy Consumption

By using simulation, systems with the lowest energy consumption can be designed. This is achieved by adjusting the recovery rate and operating pressure.

3. Predicting Long-Term Performance

IMSDesign can predict the system’s performance over time and analyze factors such as membrane fouling and performance degradation.

3. Process Optimization

For existing systems, simulation helps identify weaknesses and provide solutions to improve performance.

Real-world Examples of Successful IMSDesign Applications in Industrial Projects

1. Mineral Water Production Plant in the United Arab Emirates

One successful project using IMSDesign was implemented in the United Arab Emirates, where an industrial water treatment system was designed for mineral water production.

- Challenges: Low input water quality and high salinity.

- Results: The system designed with IMSDesign reduced energy costs by 20% and increased efficiency.

2. Power Plant in Saudi Arabia

In a power plant, IMSDesign was used to supply cooling water from seawater.

- Challenges: The need for a large volume of treated water.

- Results: The design of a two-stage system with a recovery rate of 50% resulted in significant cost savings.

3. Municipal Water Treatment Plant in India

In an urban project in India, IMSDesign was used to design a drinking water system from underground sources with high TDS.

- Challenges: High water salinity and limited financial resources.

- Results: The system designed with this software was able to bring the water quality to drinking standards

Comparison of Wastewater Treatment Design and Simulation Software

1. IMSDesign

IMSDesign software was developed by Hydranautics for the design of reverse osmosis (RO) systems. This software is mainly used for the selection and design of reverse osmosis membranes in industrial and municipal water treatment systems.

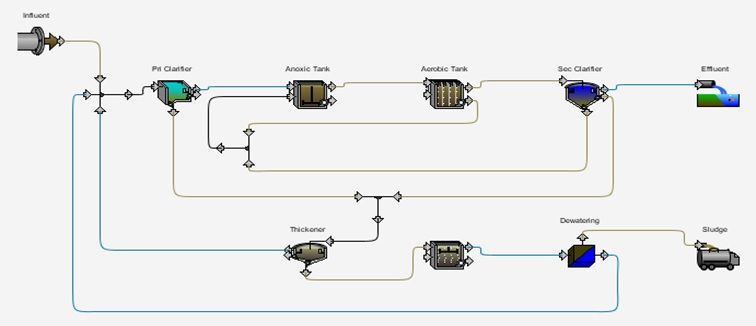

2. GPS-X

GPS-X software is an advanced tool for modeling and simulating wastewater treatment processes, produced by Hydromantis. This software is suitable for complex projects and research applications due to its high flexibility and the ability to adjust various parameters.

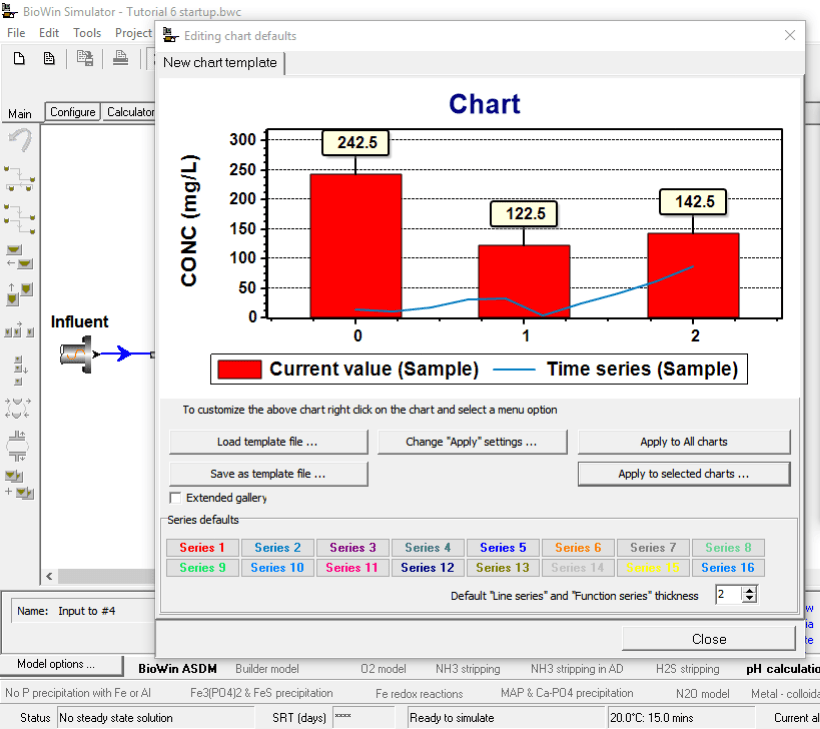

3. BioWin

EnviroSim BioWin software is a powerful tool for simulating wastewater treatment processes developed by EnviroSim. This software allows for accurate modeling of biological, chemical, and physical processes in municipal and industrial wastewater treatment plants.

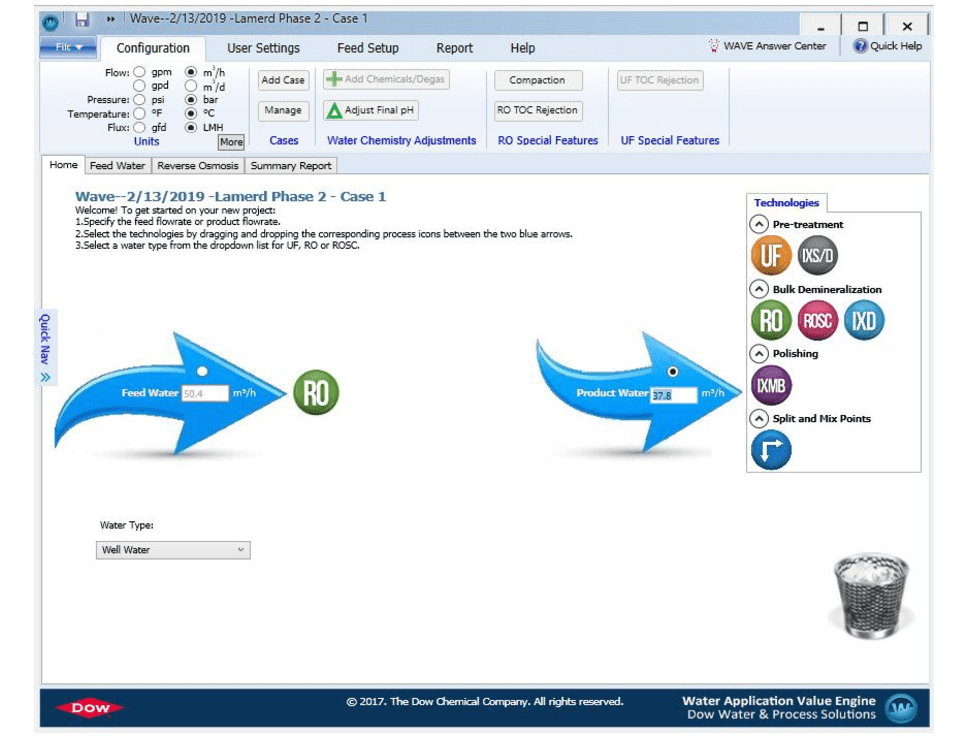

4. Wave Software

Developed by DuPont Water Solutions, Wave Software is a comprehensive tool for designing and simulating water treatment processes using various technologies such as reverse osmosis (RO), ion exchange, and nanofiltration (NF) systems.

Software Comparison Table

| Features | Wave | IMSDesign | GPS-X | BioWin |

|---|---|---|---|---|

| Main Application | Designing and simulating water treatment processes | Designing reverse osmosis systems | Advanced design and simulation of treatment plants | Simulation of wastewater treatment processes |

| User Interface | Graphic and comprehensive | Simple and focused on membrane design | Graphic with high flexibility | Graphic and user-friendly |

| Suitable For | Designing industrial and municipal water treatment processes | Reverse osmosis systems | Research projects and complex treatment plants | Municipal and industrial treatment plants |

| Required Knowledge | Knowledge of water and chemical treatment processes | Suitable for professional and experienced users | Advanced parameter adjustments expertise | Basic knowledge of treatment processes |

| Unique Features | Support for various water treatment technologies | Extensive database for selecting suitable membranes | High flexibility in detailed process adjustments | Accurate modeling of biological and chemical processes |

| Limitations | Requires expertise in using advanced features | Focused on reverse osmosis system design | Complexity in learning and usage for beginners | Requires additional resources for complex simulations |

| Industrial Application | Designing hybrid water treatment processes | RO system design for large and complex systems | Specialized simulation for large and complex systems | Simulation and optimization of large-scale wastewater plants |

IMSDesign’s Role in Reducing the Environmental Impact of Wastewater Treatment Plants

IMSDesign plays a pivotal role in minimizing the environmental footprint of wastewater treatment plants by optimizing system design and operation. Through reduced energy consumption, optimized chemical usage, and decreased wastewater volume, this software significantly contributes to environmental protection.

Key Benefits of IMSDesign:

- Energy Efficiency: By accurately simulating and optimizing operational parameters, IMSDesign enables significant reductions in energy consumption. For instance, it can calculate the optimal operating pressure for membranes based on influent water conditions, preventing excessive energy use.

- Chemical Reduction: IMSDesign minimizes the overuse of chemicals like coagulants and flocculants by precisely predicting the system’s chemical requirements. This not only decreases costs but also prevents the discharge of harmful chemicals into the environment.

- Wastewater Volume Reduction: Through the design of efficient systems and the simulation of various scenarios, IMSDesign enables a reduction in wastewater volume and improves its quality.

- Enhanced System Efficiency: By simulating and analyzing the performance of existing systems, IMSDesign identifies bottlenecks and inefficiencies, suggesting improvements. This leads to reduced resource wastage and overall increased system efficiency.

Conclusion

IMSDesign is a powerful and versatile tool that is driving advancements in the water and wastewater industry. It empowers engineers to design and construct higher-quality, more cost-effective, and efficient treatment systems. By addressing the challenges faced in wastewater treatment, IMSDesign contributes to a more sustainable future. As technology advances, IMSDesign is poised to play an even more significant role in the industry.