Design of Semi-Industrial and Laboratory-Scale Process

دی ۷, ۱۴۰۳

Engineering and Implementation of Industrial Wastewater Treatment

دی ۱۰, ۱۴۰۳Introduction

Industrial water is known as one of the basic resources in production and industrial processes. Considering the increase in population and the need for more production, attention to the design and construction of industrial water units is of particular importance. Also, in today’s world, with rapid industrial developments and population growth, the issue of industrial waste management has become one of the serious challenges in the field of environment and public health.

Industrial units, as production centers, naturally produce significant amounts of polluted effluents, which include harmful chemicals, heavy metals, and other pollutants. These effluents not only affect the quality of water resources, but can also harm the health of ecosystems and humans. In the following, we will examine the key components of the design of industrial water and wastewater units, the standards, required materials and equipment, as well as the stages of construction and implementation of these units.

Steps in Designing Industrial Water Units

1. Needs Analysis and Project Specifications

The first step in designing industrial water units is the analysis of the specific needs of the project. This includes determining the required amount of water, water quality, and the type of industrial process. For instance, in the food industry, water quality must reach a high standard, while in heavy industries, lower quality water may suffice. In petrochemical industries and power plants, there is a greater need for advanced water treatment as the water must be completely deionized. This step helps designers define more precise specifications for the industrial water system.

2. Selection of Technology and Equipment

After analyzing the needs, the next step is selecting the appropriate technology and equipment. This includes choosing pumps, treatment systems, and water storage solutions. Equipment should be selected based on the quality and volume of water required. For example, various filters, reverse osmosis systems, or deionization may be used for water treatment. The correct selection of equipment can significantly impact the efficiency and operational costs of the industrial water unit.

3. Design of Piping System

A key aspect of designing industrial water units is the piping system. Proper piping design helps prevent pressure drops and ensures uniform water distribution throughout the unit. This stage involves hydraulic calculations and selecting suitable materials for the pipes. Particularly in industrial environments, resistance to corrosion and pressure is very important.

4. Implementation of Control and Monitoring System

To ensure optimal performance of the industrial water unit, a control and monitoring system is necessary. These systems can include sensors and measuring devices that continuously monitor the quality and quantity of water. By utilizing these systems, quick responses to changes in water conditions and quality can be made, allowing for necessary actions to be taken.

5. Testing and Commissioning

After the construction and installation of equipment are completed, the testing and commissioning phase begins. This phase involves checking the system’s performance and ensuring that all equipment operates correctly. Adjustments and modifications may be needed during this stage to optimize the system and ensure it adequately meets project requirements.

6. Maintenance and Repairs

After commissioning, regular maintenance and repairs of the industrial water unit are of special importance. This includes scheduling periodic inspections, replacing worn-out parts, and updating equipment. Proper maintenance can extend the lifespan of the equipment and reduce operational costs.

Design of Water Treatment Systems

These systems must be designed to effectively remove contaminants and ensure the required quality of water. The use of modern technologies such as biological treatment, chemical treatment, and membrane filtration can be effective in this regard. Designing water treatment systems in the petrochemical industry, power plants, and other industries requires a thorough and comprehensive process that includes various stages from initial analysis to modeling and implementation. In the following sections, we will detail the stages of designing these systems, the software used, as well as the plans and modeling involved.

Stages of Water Treatment System Design

1. Analysis of Water Needs and Specifications

– Identification of Water Sources: Identifying existing water sources, including surface water, groundwater, or recycled water.

– Water Quality Analysis: Measuring various parameters such as pH, hardness, contaminant concentrations, and other characteristics. This stage is typically performed using specialized laboratories and analytical equipment.

2. Determination of Standards and Requirements

– Review of Standards: Studying national and international standards related to water quality, such as EPA and WHO standards.

– Establishing Requirements: Identifying specific needs for each industry and determining the expected quality of the output water.

3. Selection of Treatment Processes

– Pre-treatment: The first stage in water treatment systems is pre-treatment. In this stage, raw water is collected from various sources such as rivers, lakes, or wells. The water at this stage may contain suspended particles, organic materials, and other contaminants. Pre-treatment typically involves the use of mesh filters, sedimentation systems, and screening to remove larger particles and initial contaminants

Physical Methods

In this stage, water is treated using physical methods. Physical treatment includes processes such as filtration, sedimentation, and flotation. Sand and carbon filters are commonly used to remove suspended particles, odors, and undesirable tastes from water. This stage helps reduce the pollution load of the water and improve its quality.

– Filtration: This process involves passing water through a filter that can be made from various materials such as sand, charcoal, or thin membranes. This method is effective for removing larger particles, debris, and microorganisms. For example, in water treatment plants, sand filters are used to eliminate suspended particles.

– Sedimentation: In this process, water is held in a tank for a specified period to allow suspended particles to settle at the bottom. This method is very effective for removing heavier particles from water, such as soil and sand. An example of this method can be sedimentation tanks in treatment facilities.

Chemical Methods

In the third stage, chemical treatment is performed. In this stage, specific chemicals are added to the water to remove particular contaminants. For instance, the use of chlorine for disinfecting water and eliminating bacteria and viruses is common. Additionally, chemicals like poly-electrolytes are used to improve the sedimentation process and remove suspended particles.

– Chlorination: This process involves adding chlorine to water to eliminate bacteria and viruses. Chlorine acts as a strong disinfectant and can effectively reduce microbial contamination. For example, in many treatment plants, chlorine is added in the final stage of treatment to ensure water safety.

– Chemical Pre-treatment: In this method, chemicals such as aluminum sulfate are used for coagulating suspended particles. These chemicals cause smaller particles to stick together and become larger, which can then be easily separated from the water. This method is typically employed in the early stages of water treatment

Biological Methods

Biological treatment refers to the use of microorganisms to remove organic pollutants and nutrients from water. This process is typically carried out in wastewater treatment facilities, but it is also utilized in some industrial water treatment systems. Microorganisms help improve water quality by breaking down organic matter.

– Activated Sludge: In this process, bacteria are used to decompose organic materials in water. These bacteria are placed in a tank where they convert organic matter into CO2 and water. This method is commonly applied in wastewater treatment plants.

– Phytoremediation: In some treatment systems, plants are used to absorb and break down pollutants. Plants can consume nitrogen and phosphorus present in the water, thereby improving water quality. This method is also known as treatment using constructed wetlands.

Reverse Osmosis

One of the most effective methods of industrial water treatment is reverse osmosis. In this process, water is forced through a semi-permeable membrane that allows only water molecules to pass through. This method helps remove ions, minerals, and other contaminants, producing very high-quality water. Reverse osmosis is especially used in sensitive industries such as pharmaceuticals and electronics.

Final Treatment

After completing the previous treatments, the final treatment stage is conducted. This stage involves the use of methods such as UV or ozone for the final disinfection of water. These processes help eliminate microorganisms and bacteria, ensuring the water quality for industrial uses.

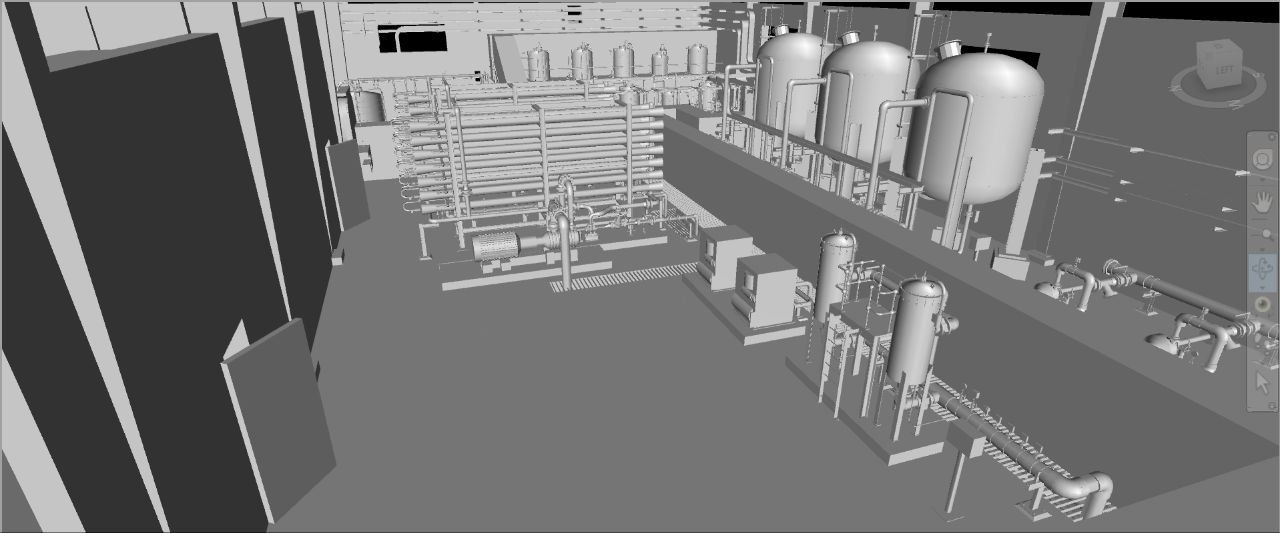

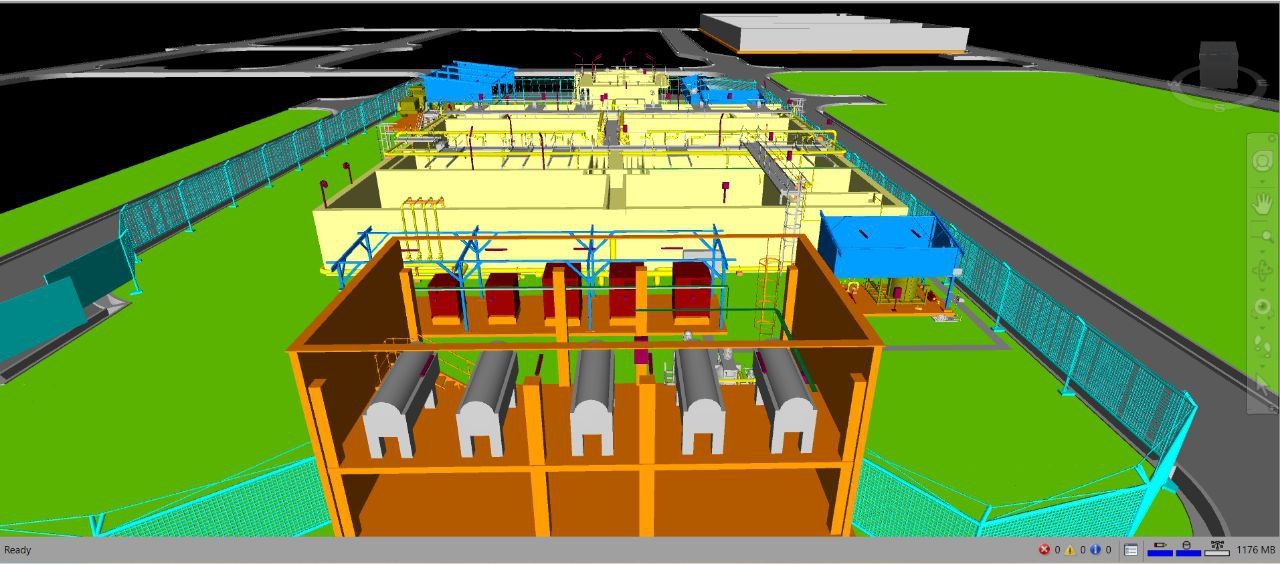

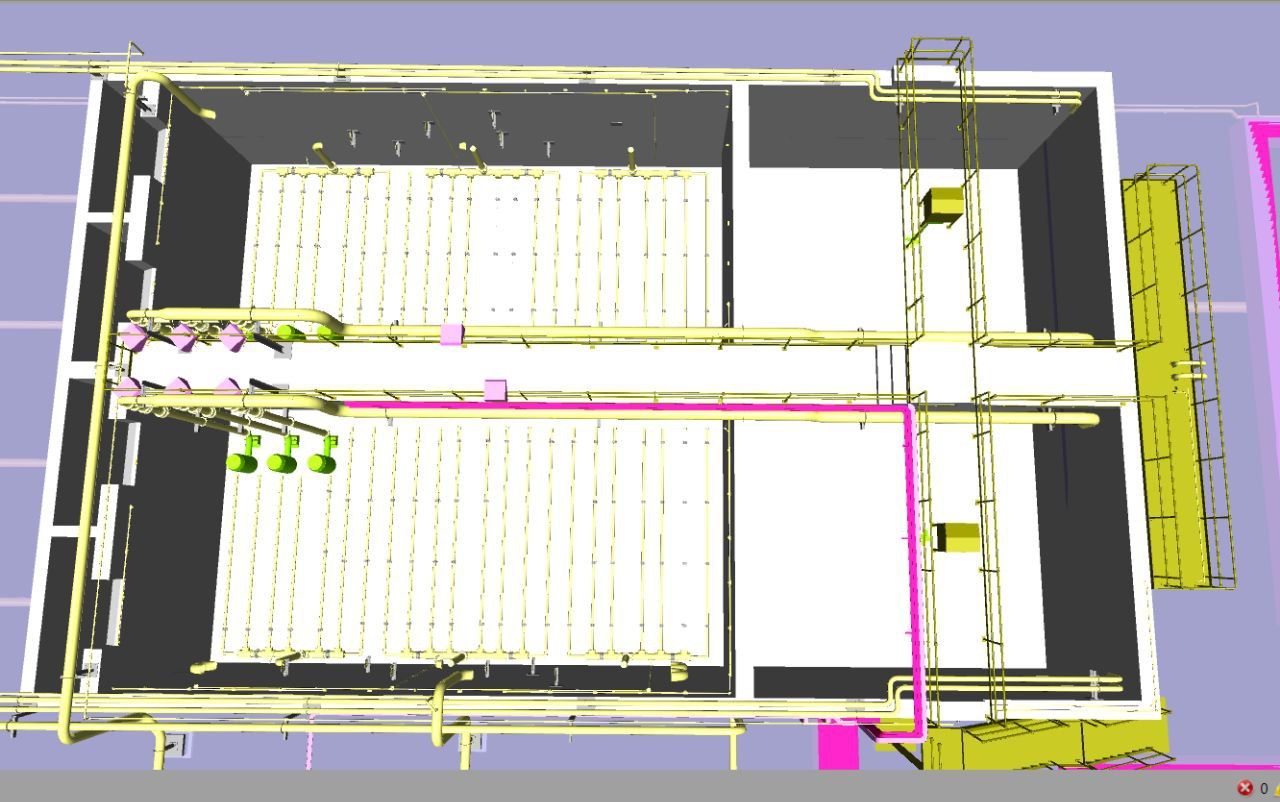

4. Modeling and System Design

Software Used:

– AutoCAD: For drawing technical maps and designing equipment.

– Aspen Plus or HYSYS: For simulating chemical processes and designing industrial systems.

– COMSOL Multiphysics: For multiphase simulations and examining physical interactions.

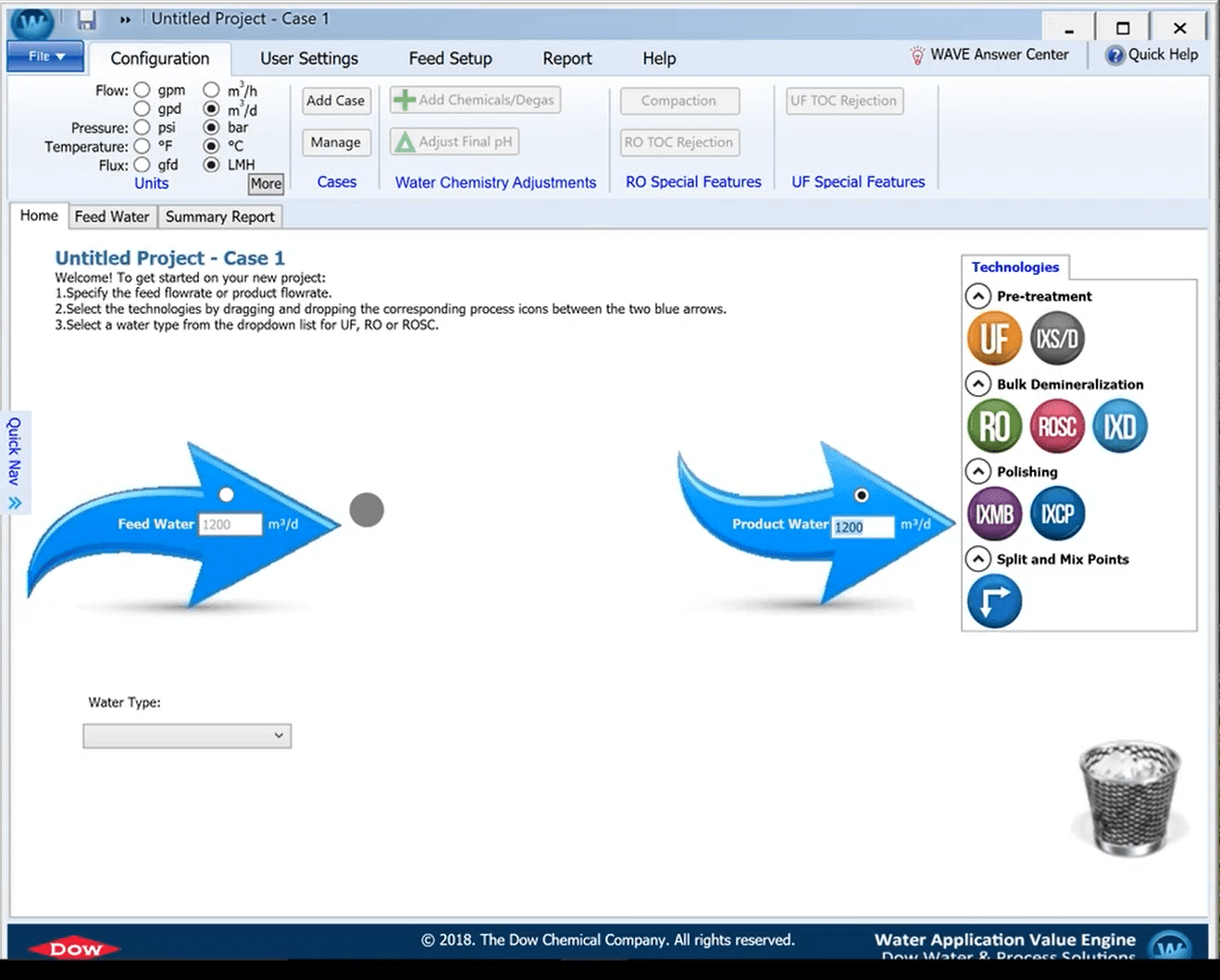

– WAVE: The Wave software is a powerful tool for designing and simulating water treatment systems developed by DuPont Water Solutions. This software is especially useful for engineers and designers working with advanced water treatment technologies such as reverse osmosis (RO), ultrafiltration (UF), and nanofiltration (NF).

WAVE provides a comprehensive simulation environment, allowing users to predict the precise performance of treatment systems and create optimal and economical designs. By focusing on cost reduction, increased efficiency, and improved quality of produced water, this software helps users execute their projects with greater confidence.

– Designing Process and Instrumentation Diagrams (P&ID) and equipment layout drawings. These diagrams include details of equipment, piping, and connections between units.

– System Modeling: Creating dynamic models to predict system performance under various conditions and optimize processes.

5. Execution and Installation

– Equipment Construction and Installation: Implementing the design and installing equipment on-site.

– Testing and Commissioning: Conducting performance tests to ensure the system operates correctly and meets standards.

– Monitoring and Control: Utilizing SCADA software to monitor system performance and collect data.

– Preventive Maintenance: Planning for periodic repairs and maintenance to extend the equipment’s lifespan.

Continuous Improvement

– Data Analysis: Collecting and analyzing performance data to identify weaknesses and improvement opportunities.

– Technology Upgrades: Implementing new and updated technologies to enhance efficiency and reduce costs.

Industrial Wastewater

Designing and constructing industrial wastewater treatment systems is essential for environmental protection and addressing environmental challenges. These systems must be designed to effectively remove various types of pollutants. Therefore, understanding and thoroughly analyzing the processes that generate wastewater, their physical and chemical characteristics, and existing treatment methods is of utmost importance.

In this context, the design of wastewater treatment systems must be carried out in accordance with legal requirements and environmental standards. These systems can include physical, chemical, and biological methods, each with its own advantages and disadvantages. For example, physical methods such as sedimentation and filtration are suitable for removing suspended particles and organic materials, while chemical methods like oxidation are effective for eliminating specific pollutants and toxins. Additionally, biological processes are recognized as a sustainable and economical option due to their ability to biologically degrade pollutants.

Furthermore, the design of treatment systems should consider factors such as the volume of wastewater produced, its chemical composition, operational costs, and the ability to adapt to changes in environmental standards. These factors can significantly influence the choice of technology and treatment methods.

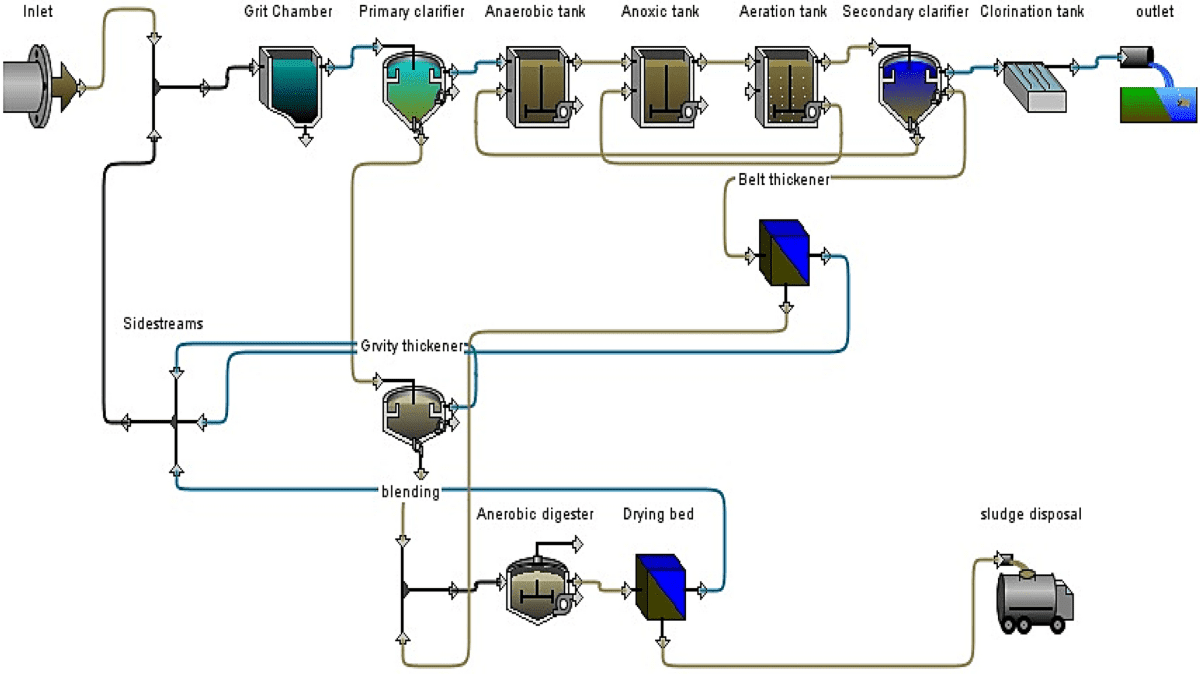

Stages of Wastewater Treatment System Design

1. Wastewater Analysis

– Identification and Assessment of Chemical Composition: The first step in designing a treatment system is to identify the physical and chemical characteristics of the wastewater. This includes various tests to determine the concentration of pollutants, pH, temperature, and other influencing factors.

– Estimation of Wastewater Volume and Generation Rate: Determining the volume of wastewater produced over time and under different conditions helps engineers accurately calculate the dimensions and capacity of the treatment system.

2. Selection of Treatment Method

– After analyzing the wastewater, the next step is to select appropriate treatment methods. These methods may include physical processes (such as filtration and sedimentation), chemical processes (such as oxidation), and biological processes (such as biological treatment). The choice of treatment method depends on the type and concentration of pollutants as well as regulatory requirements.

Physical Treatment

This method involves preliminary treatment stages that eliminate suspended particles and larger materials from the wastewater using physical methods. Common methods include:

– Filtration: Utilizing filters to separate suspended particles.

– Sedimentation Systems: Employing gravitational force to separate heavier materials.

– Flotation: Using air bubbles to separate lighter suspended particles.

Chemical Treatment

In this method, chemical reactions are employed to remove pollutants. This includes:

– Reduction and Oxidation: For the removal of heavy metals and organic materials.

– Nitrification: Converting ammonia to nitrate.

– Pre-treatment: Adding chemicals to alter the chemical properties of pollutants and facilitate their removal.

Biological Treatment

This method utilizes microorganisms to degrade organic materials present in wastewater. Common methods include:

– Aerobic Processes: Using oxygen to decompose organic materials.

– Anaerobic Processes: Microorganisms decompose organic materials in the absence of oxygen.

– Biological Organization: Utilizing bacteria and other microorganisms to degrade pollutants under controlled conditions.

Advanced Treatment

These methods are typically performed in the final stages of treatment to help eliminate specific and resistant pollutants. Advanced methods include:

– Ozonation: Utilizing ozone for oxidation and removal of pollutants.

– Nanotechnology: Employing nanoparticles for the adsorption and removal of pollutants.

– Membrane Filtration: Including reverse osmosis and nanofiltration processes to separate pollutants based on size and electrical charge.

Combined Treatment

In many cases, a combination of different methods is employed to achieve optimal results. For example, a biological system may be combined with chemical or physical treatment to enhance the efficiency of pollutant removal.

Water Management and Recycling

Ultimately, focusing on optimal water management and striving for the recycling of wastewater contribute to reducing water consumption and preserving natural resources. This is particularly significant in large industries such as petrochemicals and steel, which require substantial amounts of water.

3. System Component Design

At this stage, the various components of the treatment system, including tanks, pumps, aeration systems, and filters, are designed. This design must consider performance, safety, and economic requirements.

4. Simulation and Modeling

This stage involves the use of specialized software to simulate the performance of the treatment system. Simulation allows engineers to analyze the effects of varying parameters on system performance and make necessary optimizations.

Design and Simulation Software

In the design and simulation of industrial wastewater treatment systems, several specialized software tools can assist engineers and researchers in this field:

1. COMSOL Multiphysic

– COMSOL is a powerful tool for multiphysics modeling that can aid in simulating physical, chemical, and biological processes in wastewater treatment systems.

2. HYSYS

– HYSYS is another widely used software for simulating chemical processes and wastewater treatment, helping engineers model complex processes effectively.

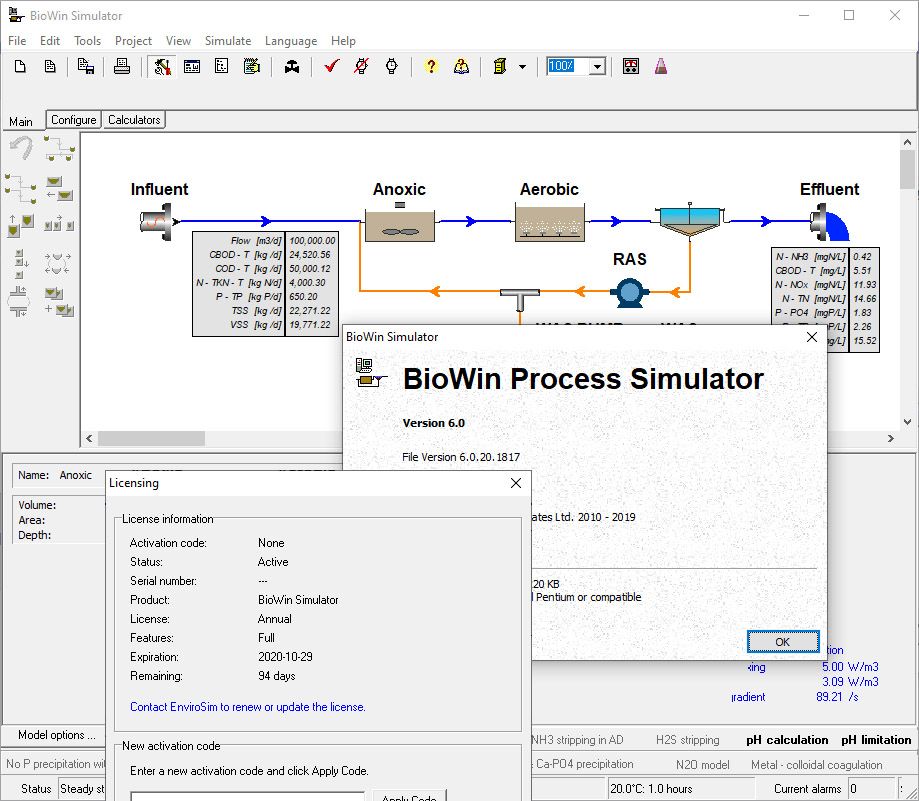

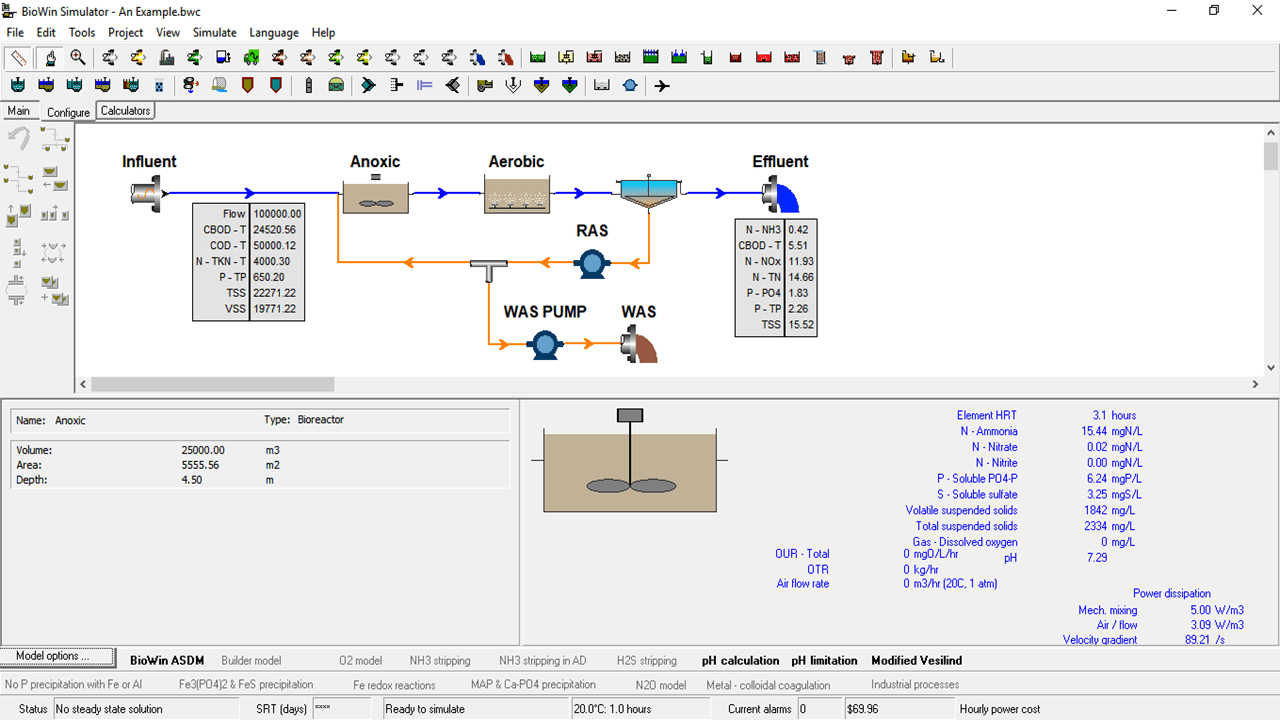

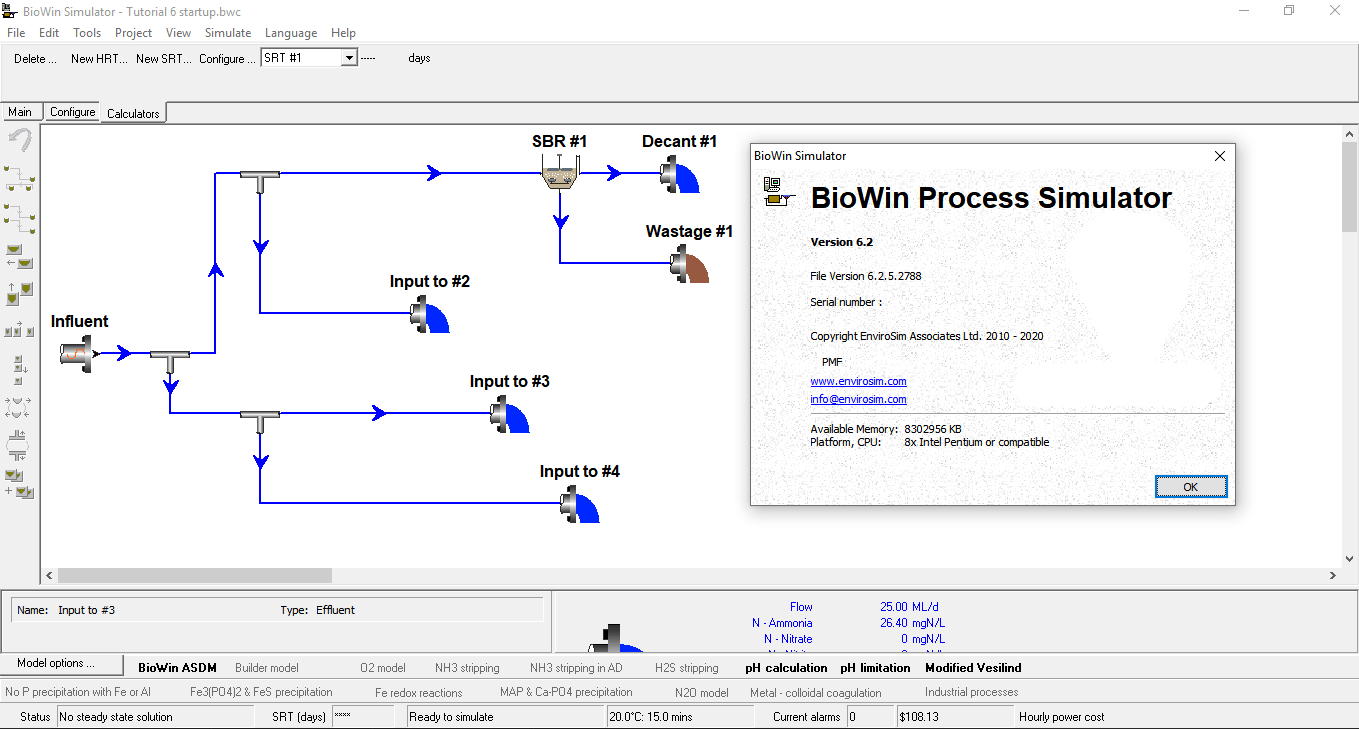

3. EnviroSim BioWin

EnviroSim BioWin is a specialized software for simulating the treatment processes of chemical and industrial wastewater, incorporating various models and methods of chemical, physical, and biological treatment. Using the BioWin wastewater treatment design software, which is tailored for chemical engineering, you can advancedly simulate biological, chemical, and physical processes in wastewater treatment and achieve your desired results.

When utilizing EnviroSim BioWin, you can simplify your simulations with the aid of various tables and charts for convenience and improved outcomes. The software also allows for the examination of water chemistry models to calculate pH, as well as mass transfer models for simulating oxygen and other gas-liquid reactions.

Examples of Simulations Conducted with This Software

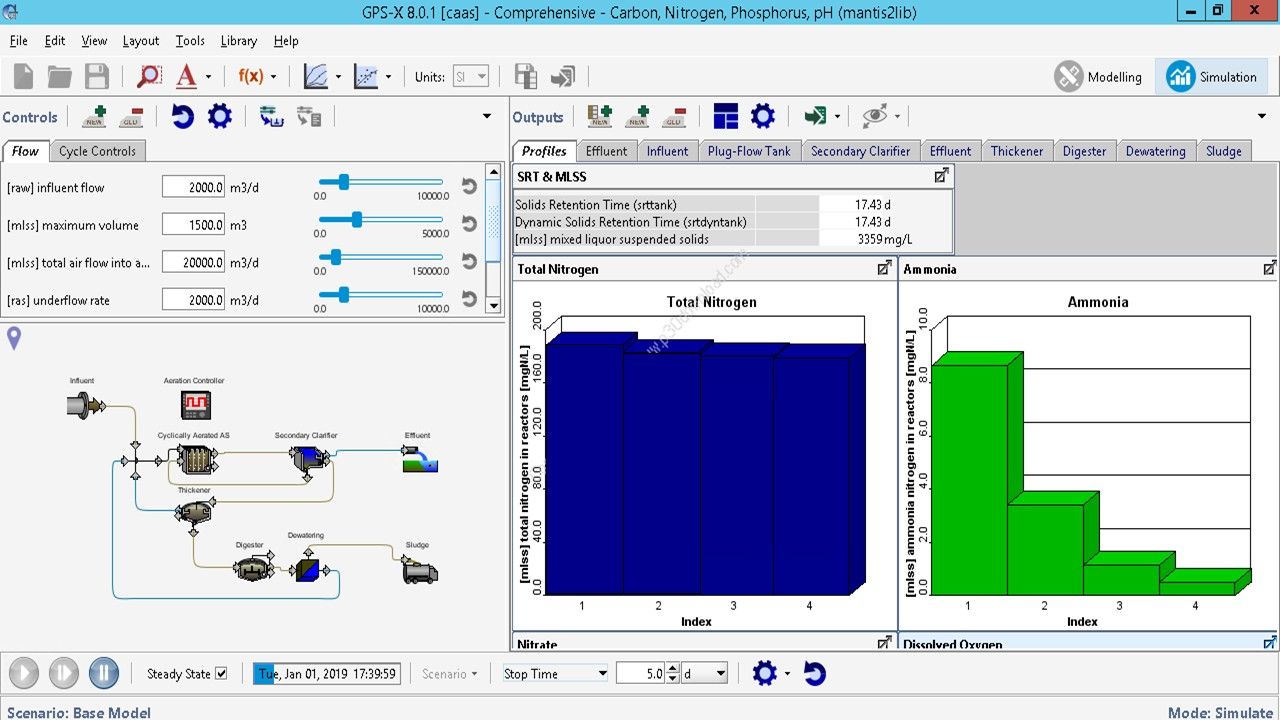

4. GPS-X Software

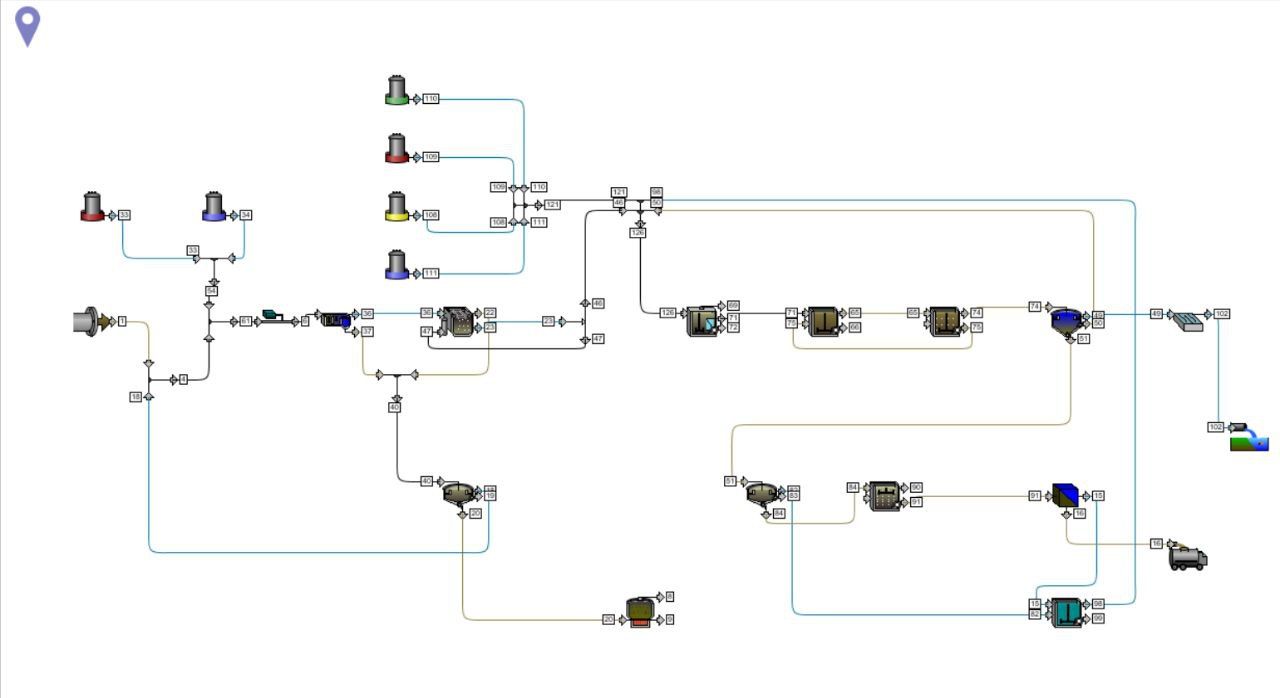

GPS-X is a comprehensive and powerful software for simulating, modeling, and analyzing wastewater treatment processes. This advanced tool is developed by Hydromantis Environmental Software Solutions, Inc. and is widely used in industry and scientific research. GPS-X enables users to dynamically and stably model complex biological, physical, and chemical treatment processes.

One of the key features of GPS-X is its high flexibility in designing and configuring processes. The software supports standard models such as ASM (Activated Sludge Models), allowing users to simulate various processes, including biological reactors, sedimentation, aeration, and filtration, with high detail.

By utilizing GPS-X, engineers can optimize the performance of treatment systems, identify potential issues, and provide cost-effective and sustainable solutions. Additionally, due to its user-friendly graphical interface and advanced analytical tools, the software is a popular choice among environmental professionals, students, and researchers.

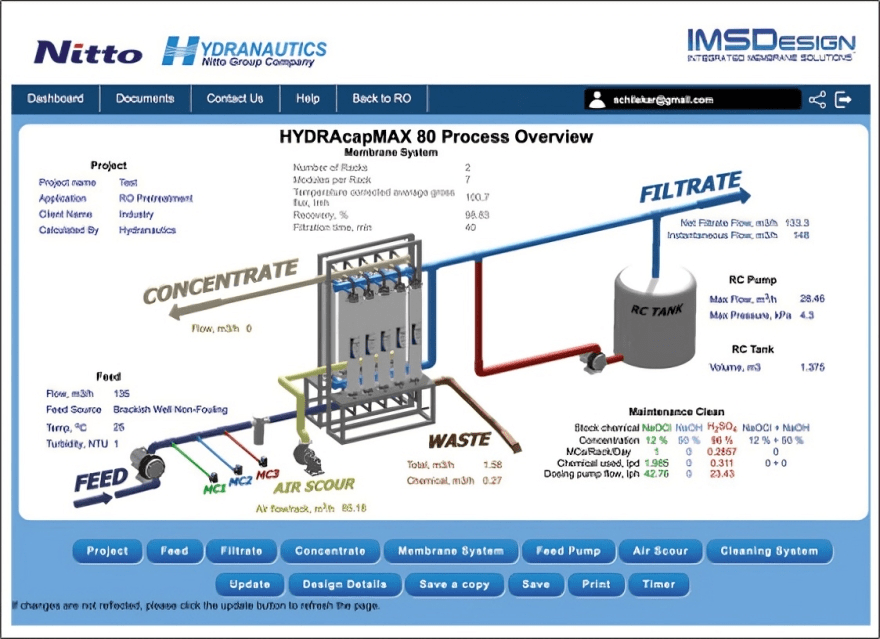

5. IMSDesign Software

IMSDesign is one of the most advanced engineering tools in the field of water and wastewater treatment, enabling industry professionals to design and simulate reverse osmosis (RO) systems with exceptional precision. Developed through the efforts of industrial experts and environmental engineers, this software has become an essential tool for optimizing treatment processes by providing accurate analyses and advanced capabilities.

Given the increasing importance of ensuring safe water supply and protecting the environment, the use of software like IMSDesign, capable of accurately simulating the behavior of treatment systems, is inevitable. This software assists engineers by allowing for detailed assessment of incoming and outgoing water quality, dynamic system simulation, and energy consumption optimization, leading to better design solutions for various applications.

Notable features of IMSDesign include an easy-to-use interface and deep data analysis capabilities, making it accessible even for novice users. By utilizing this software, design time and costs can be significantly reduced, resulting in higher efficiency of treatment systems.

Anil Pars Industrial Process Company

Anil Pars Industrial Process Company is one of the pioneers in the water and industrial wastewater treatment industry. Utilizing cutting-edge technologies and a skilled team of engineers and specialists, the company focuses on designing and constructing advanced water and wastewater treatment systems. The goal of this company is to provide innovative and efficient solutions for water resource management and reducing environmental pollution. Anil Pars Industrial Process Company assists its clients in achieving environmental standards while simultaneously reducing costs through the use of modern equipment and technologies.

In addition to designing and manufacturing treatment equipment, the company also offers consulting services in optimizing water and wastewater treatment processes. Considering the specific needs of each industry and various environmental conditions, Anil Pars Industrial Process Company provides customized solutions tailored to customer requirements. This approach enables the company to contribute to sustainable development goals and environmental preservation while improving the quality of consumable water and industrial wastewater.

Skills of APIPCO

– Basic and detailed design of chemical

– design of oil, gas, and petrochemical

– Sizing of water treatment

– wastewater treatment

– Reverse Osmosis (RO) systems

– Modeling and simulation

– Process flow diagrams (PFD) and piping and instrumentation diagrams (PID)

– Design of process equipment (pumps, compressors, drums, various distillation columns, heat exchangers)

– Preparation of hydraulic calculation documents

– Familiarity with IPS standards (730 & 725) for designing industrial and municipal wastewater treatment plants

– Knowledge and implementation of CIP processes

Software Used for Design

– Aspen Hysys

– GPS-X

– WAVE

– IMS-DESIGN

– COMSOL

– OLGA

– HTRI

– AUTOCAD

– MATLAB

Designed Units

Among the units designed by Anil Pars Industrial Process Company are the Coagulation Tank, A2O Biological Wastewater Treatment, Concentrator, Digester, Equalization Tank, Pump Station, Stripping Unit for VOC removal, and Bar Screen.

Conclusion

The design and construction of industrial water treatment units is a complex, multi-stage process that requires deep knowledge across various engineering fields. From needs analysis and selection of appropriate technology to implementation and maintenance, each stage holds significant importance. Given the challenges in water supply and the need to optimize industrial processes, a focus on the proper design of these units can greatly improve efficiency and reduce costs.

The design and construction of industrial wastewater treatment systems is a complex process that demands precise analysis and the use of modern simulation and modeling methods. With increasing concerns about environmental issues, the development of effective and efficient systems for managing industrial wastewater has become more essential than ever. Utilizing specialized software in this field can significantly enhance performance and reduce costs, ultimately contributing to the achievement of sustainable development goals.