Comsol Training Course

مهر ۱۰, ۱۴۰۳

Comprehensive High Services in Master’s and PHD Thesis Writing

مهر ۱۱, ۱۴۰۳Introduction

The effort to understand and visualize three-dimensional space began as far back as the 6th century BC, and perhaps even earlier. 3D design is a technique in computer graphics used to create digital representations of any surface in three dimensions. 3D models are utilized across a variety of media, including video games, architecture, illustration, engineering, and more. One of the first 3D programs, Sketchpad, created by Ivan Sutherland, revolutionized computer interaction.

Over time, 3D design software expanded into other industries such as engineering, architecture, medicine, and entertainment. The initial goals of 3D software included solving complex design problems, simulating and analyzing structures, and quickly producing design variations. Today, these software tools find applications in various fields, including game development, filmmaking, product design, and engineering, as well as providing visual aids and virtual reality in diverse domains.

Main Reasons for the Existence of These Software Tools

3D software emerged out of the need for visualization and simulation of reality in different contexts. Some main reasons for the creation of these software tools include:

– Engineering and Design Visualization: In various industries like architecture, mechanics, and fashion, there’s a need for precise 3D modeling and design.

– Simulation and Training: 3D software is used to simulate complex systems or processes in scientific and educational contexts.

– Technological Advancements: With the development of computer hardware and software, creating high-detail 3D models and realistic rendering became possible.

– Productivity and Cost Reduction: Using 3D models can help prevent errors during the construction phases, thereby reducing design and production costs.

These factors and needs, along with technological advancements, have driven the growth and development of 3D software.

History of 3D Design Software

AVEVA software was established in 1967 to aid in the design and management of industrial facilities. The PDMS software was introduced in 1980 for advanced facility design and modeling. Revit, which gained attention in 2000 for its building information modeling capabilities, is also used in the oil and gas industries. In 2010, AutoCAD Plant 3D was released, focusing on complex industrial facility design, including piping design capabilities.

3D Design Software in the Oil and Gas Industry

AutoCAD Plant 3D

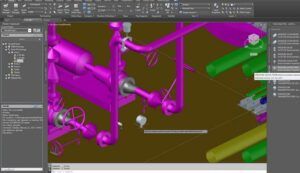

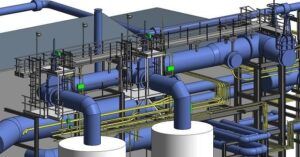

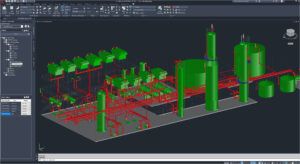

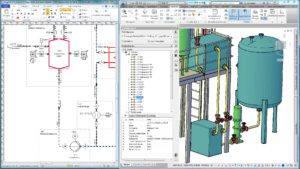

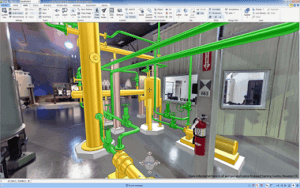

This software, part of Autodesk’s offerings, is used for design in specialized industries such as oil, gas, and petrochemical projects. Its familiar AutoCAD environment allows engineers to quickly learn and achieve modern 3D designs for various industrial facilities or transfer chemical and petrochemical industries.

AutoCAD Plant 3D provides critical tools and features needed by designers for creating accurate factory models, including piping, structures, and equipment on the familiar AutoCAD platform. Notable capabilities include information integrity, producing and sharing orthographic and isometric drawings, advanced material reports, and managing various plant components like pumps, compressors, piping design, and equipment installation.

Advantages:

– Integration with AutoCAD: Easy for AutoCAD users to learn.

– Piping design capability: Professional and precise piping and equipment design.

– Rapid 2D drawing production: Quick generation of engineering drawings.

Disadvantages:

– Limited simulation capabilities: Its simulation features are restricted.

– High cost: Licensing can be expensive for some companies.

AVEVA

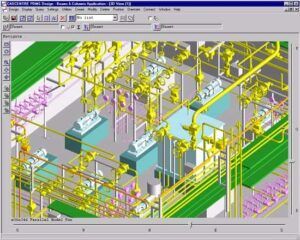

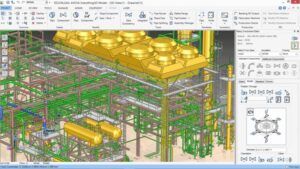

AVEVA Instrumentation is a powerful software for designing and producing engineering maps and documentation for control and instrumentation systems. It features a sophisticated graphical interface with four integrated modules that support all project phases, including design, installation, commissioning, and maintenance.

AVEVA E3D is the most advanced 3D design solution for process plants, offshore industries, and power generation. It enables powerful visualizations and collision-free 3D designs across engineering departments and rapidly generates accurate drawings and reports to reduce costs and project risks.

Advantages:

– Advanced design capabilities: Interactive tools for modeling.

– Management of large projects: Suitable for large teams and complex projects.

– Intelligent analysis: Use of AI technologies in analysis.

Disadvantages:

– Complexity: Relatively high learning curve, posing challenges for new users.

– High licensing costs: Can be costly for small projects or startups.

Revit

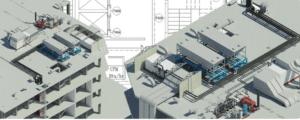

Revit, primarily developed for Building Information Modeling (BIM), is also used in the oil and gas industries. It offers extensive capabilities for designing, simulating, and managing large and complex projects.

Applications of Revit in Oil and Gas Industries:

– 3D Modeling: Allows engineers and architects to create precise 3D designs of oil and gas facilities, helping to grasp dimensions, scales, and relationships between components.

– Analysis and Simulation: Revit’s analytical tools help simulate system behaviors, identifying potential issues before execution.

– Cross-disciplinary Coordination: Facilitates coordination among various engineering disciplines, reducing conflicts and errors during construction.

– Cost and Time Reduction: Precise design and appropriate planning can lead to reduced project costs and time.

Advantages:

– High accuracy: Precise 3D modeling reduces design errors and enhances documentation accuracy.

– Time and cost management: Integrated information helps project managers accurately predict and control time and funding.

– Quick access to changes: Automatic updates of design changes across all documents and views save time.

– Energy review and analysis: Energy analysis tools allow engineers to evaluate design impacts on energy consumption and efficiency.

PDMS Software

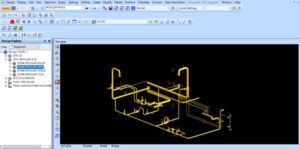

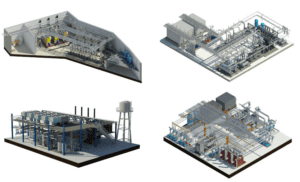

PDMS stands for Plant Design Management System and is a product of AVEVA UK. It is one of the most utilized and effective 3D modeling software platforms in the oil and gas and petrochemical industries, capable of design, modeling, and system management simultaneously. Alternative software includes PDS and Autoplant, but PDMS is preferred in many countries due to its strength and flexibility.

Key Features:

– 3D Design: Enables the 3D design of facilities and equipment, providing users with a better view of projects and pre-construction problem identification.

– Information Management: Very useful for managing project data and coordinating multiple engineers and teams simultaneously.

Advantages:

1. High productivity: Integrated design process significantly reduces design and modification times.

2. High precision: Advanced modeling and simulation tools offer considerable design accuracy.

3. Collaboration capability: Supports simultaneous work among multiple users.

4. Project management: Includes project management tools for monitoring schedules, costs, and resources.

Disadvantages:

1. High cost: PDMS is often pricier than some competitors.

2. Training requirement: Mastery requires time and training, possibly challenging for individuals unfamiliar with complex software.

Aveva E3D Software

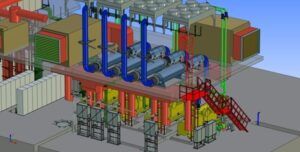

AVEVA E3D, or AVEVA Everything3D, is a leading engineering 3D design software addressing process design needs in processing, maritime, and energy industries. Utilizing new 3D graphics technologies and advanced data management, it enables multi-disciplinary design capabilities.

Advantages:

– Interference-free design: Allows multi-disciplinary collaboration without conflicts, enhancing productivity.

– Automated drawing and report generation: Automatically produces accurate drawings and reports.

– Advanced user interface: A user-friendly and modern interface maximizes designers’ productivity.

– Compatibility with other AVEVA solutions: Ensures seamless data transfer and collaboration.

Conclusion

3D design software plays a pivotal role in the oil and gas industries’ design, engineering, and project management processes. These tools enable precise and realistic modeling of facilities, equipment, and infrastructures, leading to the identification and reduction of errors in design and construction stages. Other benefits include increased productivity, facilitation of collaboration among different teams, and improved project information management.

When selecting suitable software for 3D design, project-specific requirements must be considered, including cost, capabilities, ease of use, and technical support. While there are some drawbacks, such as high licensing costs and training needs, the numerous advantages of these software tools often justify the investment.

Ultimately, leveraging 3D design software enhances innovation, quality, and efficiency in oil and gas projects, empowering engineers to confidently employ advanced and creative techniques, resulting in more successful project completions. Consequently, investing in these tools is a strategic key for success in the oil and gas industry.

Our team, leveraging our expertise and experience, is capable of performing 3D designs using AutoCAD Plant 3D, PDMS, and AVEVA E3D software.