Design and Construction of Industrial Water and Wastewater Units

دی ۹, ۱۴۰۳Introduction

In today’s world, the increasing population and the growing demand for water resources have turned the effective and efficient management of wastewater into a significant challenge. Wastewater systems are recognized as one of the effective solutions for water treatment and the recovery of water resources. These systems, with the capability of removing ions and suspended particles, greatly contribute to the provision of potable and industrial water. However, the design of these systems requires precision and special attention to various factors, including the type of wastewater, operational conditions, and the specific needs of the user.

One of the innovative tools in this field is the use of three-dimensional design services, which enable accurate modeling and simulation of system performance. This approach allows engineers to evaluate and optimize the performance of various systems before actual implementation. By utilizing advanced simulation software, it is possible to analyze the behavior of systems under different conditions, thereby identifying and addressing potential problems and challenges. Further explanations will be provided in the following sections.

What is a Wastewater Treatment Plant?

Wastewater generated in urban and industrial areas is collected by a network and transported to a wastewater treatment plant. At the treatment plant, physical, chemical, and biological processes are performed on the incoming wastewater. After treatment, the effluent is discharged free of any environmentally harmful pollutants. Depending on the type of wastewater, the treatment stages may vary and consist of multiple processes.

Importance of Designing Industrial Wastewater Treatment Plants

During the production stages of various products in manufacturing and petrochemical units, refineries, chemical and biological pollutants are introduced into the wastewater. The direct discharge of these pollutants can lead to the spread of multiple diseases, genetic mutations, contamination of groundwater, and other severe environmental impacts. Therefore, no factories or industries are permitted to discharge untreated wastewater into rivers, streams, or natural environments. In other words, the design and construction of industrial wastewater treatment plants are essential in today’s industrial parks.

Stages of Wastewater Treatment System Design

A. Needs Identification and Analysis

– Local Needs Assessment: Analyzing the type of wastewater generated (industrial, domestic, agricultural) and identifying pollutant sources.

– Standards Determination: Awareness of local and international standards for wastewater treatment.

B. Selection of Treatment Methods

– Physical: Includes methods such as separation, sedimentation, and filtration.

– Chemical: Involves oxidation, nitrification, and the use of chemicals to reduce pollutants.

– Biological: Utilizes microorganisms to decompose organic materials. These methods include activated sludge systems, biological filters, and biological reactors.

C. System Design

– Treatment Unit Design: Each unit should be designed to provide optimal performance, including dimensions, material types, and interconnections between units.

– System Modeling: Using modeling software to simulate system performance and predict outcomes.

D. Economic and Environmental Assessment

– Cost-Benefit Analysis: Evaluating initial and operational costs of the system in comparison to its benefits.

– Environmental Impact Assessment: Identifying and evaluating the negative and positive effects of the system on the environment.

E. Implementation and Monitoring

– Installation and Commissioning: Executing the design and installing necessary equipment.

– Quality Control and Monitoring: Establishing monitoring systems to ensure effective system performance and compliance with standards.

F. Improvement and Optimization

– Review and Update: Making necessary changes and improvements based on system performance results.

– Training and Awareness: Educating staff and the local community about the importance of wastewater treatment and environmental preservation.

Parameters for Design and Construction of Wastewater Treatment Plants

In the design and construction of both large and small wastewater treatment plants in industrial units, numerous parameters must be considered beyond the regulations provided by environmental authorities and urban wastewater treatment guidelines. These parameters not only specify the methods, components, and equipment required for treatment but also facilitate budget estimation for human resource allocation. The critical design parameters for wastewater treatment plants include:

1. Site Evaluation: A thorough assessment of the proposed location, considering soil composition, permeability, wind direction, climatic conditions, and proximity to rivers and groundwater tables.

2. Wastewater Generation Assessment: Accurate determination and analysis of daily wastewater production, which varies depending on the type of industrial unit.

3. Quality Analysis of Wastewater: Detailed examination of wastewater characteristics and determination of quality indicators such as BOD, COD, TSS, etc.

4. Pollutant Identification: A comprehensive list of various contaminants present in the wastewater, including heavy metals and chemicals.

5. Treated Water Quality Standards: Specification of the desired quality of effluent post-treatment.

6. Treatment Methodology Selection: Identification of necessary treatment methods tailored to the quality parameters and types of pollutants involved.

7. Equipment Inventory: A complete and precise list of required equipment for each stage of the treatment process.

8. Budget Estimation for Equipment Purchase: Financial planning for the acquisition of necessary treatment equipment.

9. Budget for Construction: Estimation of costs for building treatment ponds or purchasing prefabricated packages.

10. Human Resource Estimation: Accurate assessment of the number of personnel required for each operational section.

11. Construction Timeline Estimation: Estimating the duration needed for the construction of the industrial wastewater treatment plant based on existing conditions.

Essential Equipment for Industrial Wastewater Treatment

The necessary equipment for industrial wastewater treatment depends on the type and volume of wastewater, the treatment method, and the capacity of the treatment plant. Below are some key equipment types used in industrial wastewater treatment:

1. Sedimentation Tanks:

These tanks are used for separating solid particles from wastewater. In these tanks, heavy particles settle to the bottom, while the treated effluent exits from the top.

2. Biofilters:

Used for the removal of organic pollutants from wastewater. In this equipment, beneficial microbes capable of degrading organic contaminants are placed within a broad medium, and wastewater flows from the top through a network system.

3. Membrane Filtration Equipment:

Employed for the removal of chemical pollutants and bacteria present in wastewater. In this equipment, wastewater passes through a semi-permeable membrane, which separates contaminants from the effluent.

4. Carbon Filters:

This equipment is used to eliminate chemical pollutants from wastewater. Wastewater flows through a bed of carbon adsorbent, where chemical contaminants are absorbed.

5. Oxidation Equipment:

In this equipment, oxygen is injected into the wastewater to oxidize chemical pollutants, converting them into less harmful substances for the environment.

Various Sections of Treatment

Screening

The screening equipment is a wastewater treatment device that separates debris and coarse materials present in wastewater, which can have either organic or inorganic origins. If large particles are not adequately removed, they can damage treatment plant equipment, particularly pumps, leading to disruptions in the wastewater treatment process.

Screens are constructed in both fine and coarse types. Coarse screens are typically rod-shaped. In terms of application and operational conditions, debris can be classified into mechanical and manual types. Manual screens are used in small treatment plants, while mechanical screens are utilized in larger facilities due to higher volumes of debris, potential environmental contamination, and human resource challenges.

Grit Removal:

Wastewater typically contains solid mineral materials such as sand, gravel, glass, and metal pieces, collectively known as grit in wastewater treatment systems. The presence of gritty materials can cause damage to pumps and treatment equipment. Therefore, the separation of these grit materials is essential. Grit removal is a physical operation and a preliminary stage of wastewater treatment that separates gritty materials, such as sand and gravel, from wastewater at the beginning of the treatment process.

Sedimentation Unit:

A sedimentation unit is used to separate effluent and sludge from each other in aerated mixtures. The primary goal of constructing the final sedimentation unit is to separate very fine particles that are suspended in the wastewater. The cellular mass produced through secondary treatment processes contains a significant organic load, which must be removed to meet wastewater standards.

Disinfection Unit:

Wastewater contains human enteric organisms that can transmit waterborne diseases, such as the poliovirus and infectious hepatitis present in the effluent. One common method for controlling these organisms is the timely and periodic disinfection of the outgoing wastewater. Optimizing and disinfecting the wastewater system can be highly effective in reducing the transmission of these organisms and preventing individuals from contracting waterborne diseases.

Sludge Storage and Management Unit:

Sludge is a byproduct of the wastewater treatment process, consisting of solid and liquid particles. During the wastewater grit removal process, sludge is directed to the sludge storage unit, where it is nearly stabilized. This process facilitates the separation of sludge from water, resulting in a sludge that is acceptable and rich in nutrients such as nitrogen and phosphorus. After dewatering and separation, the sludge becomes highly suitable for bacterial proliferation.

Equalization Unit:

This unit is designed to create balance and uniformity in the quality and quantity of the influent wastewater entering the treatment plant. Since the volume and pollution load of the incoming wastewater can vary at different times, the presence of an equalization basin helps mitigate the shock caused by sudden increases in pollutant or hydraulic load to the system. Hydraulic shock can lead to the loss of sludge, subsequently reducing the required sludge quantity and decreasing the treatment efficiency of the plant.

Pumping Station:

This unit is utilized to convey wastewater to subsequent treatment units within the facility. It generates pressure and transfers the necessary flow of wastewater to the aeration unit using submersible wastewater pumps. Additionally, the pumps in this unit are controlled by float switches.

Aeration in Wastewater Treatment Plant:

When wastewater enters the aeration tank, it is mixed with sludge, forming a mixture of sludge, water, and incoming solids. The sludge contains various live microorganisms, referred to as “workers” of the treatment plant, which utilize the incoming wastewater as a food source for their growth and reproduction. By consuming the contents of the wastewater, these microorganisms effectively treat the wastewater.

Design Guidelines for Industrial Wastewater Treatment Plants

In the design of industrial wastewater treatment plants, it is essential to consider relevant regulations and standards to achieve optimal performance and quality in wastewater treatment. Below are key design guidelines:

1. Use of Engineering Software: Employ specialized software for accurate modeling and analysis of treatment systems.

2. Adherence to Health Standards: Ensure compliance with health and safety standards throughout the design process.

3. Compliance with Environmental Regulations: Prioritize environmental laws and ecosystem preservation in the design and operation phases.

4. Utilization of Portable Equipment: Choose portable and flexible equipment suitable for various conditions.

5. Safety Regulations: Ensure personnel and equipment safety in the design and operational procedures.

6. Determining Plant Capacity: Calculate the treatment plant’s capacity based on the volume and characteristics of the incoming wastewater.

7. Use of High-Quality Equipment: Select high-quality and standardized equipment to enhance durability and efficiency.

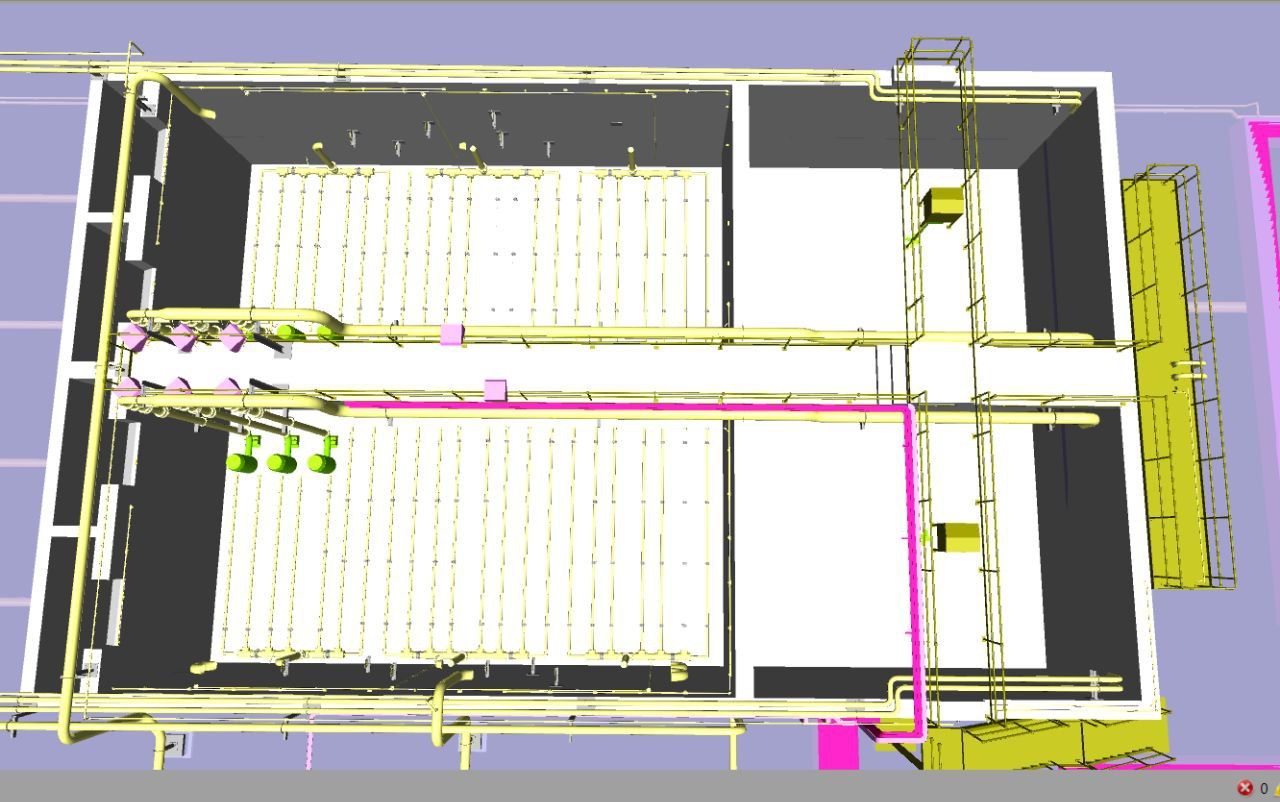

8. Three-Dimensional Designs: Three-dimensional (3D) designs play a crucial role in engineering and optimizing industrial wastewater treatment systems. These designs enable precise modeling of systems, aiding in performance optimization, cost reduction, and early identification of potential issues.

Stages of 3D Design for Industrial Wastewater Systems

A. Initial Analysis and Data Collection

– Identifying Specific Needs: Assessing system requirements based on the type of wastewater, volume, and chemical composition.

– Environmental Condition Analysis: Identifying environmental conditions and physical constraints that may impact the design.

B. Conceptual Design

– Developing Preliminary Designs: Creating initial designs based on collected data and identified needs.

– Selecting Design Software: Choosing appropriate software such as AutoCAD, SolidWorks, or CATIA for 3D design.

C. 3D Design

– Modeling Components: Creating 3D models of various system components, including tanks, pumps, and treatment units.

– Component Layout: Determining the optimal positioning of each component to maximize space efficiency and facilitate wastewater flow.

D. Simulation and Analysis

– Flow Simulation: Utilizing simulation software to analyze wastewater flow and predict its behavior within the system.

– Static and Dynamic Analysis: Examining the strength and stability of components under various loads.

E. Design Optimization

– Identifying Weaknesses: Recognizing and rectifying design weaknesses based on simulation results.

– Re-testing: Conducting re-tests to ensure the effectiveness of the optimizations made.

Benefits of 3D Design

– High Precision: 3D designs offer high accuracy, capturing detailed representations of the system.

– Enhanced Visualization: Providing a clearer image of the system to stakeholders and clients.

– Reduced Design Time: Accelerating the design process and minimizing the time required for modifications.

Challenges and Limitations

– Software Costs: Utilizing 3D design software can be expensive.

– Technical Expertise Requirement: There is a need for technical skills and expertise to create complex 3D models.

– Data Management: Managing design data and ensuring information is up-to-date is essential.

Optimization of Wastewater Treatment Systems

Optimizing and upgrading existing wastewater treatment systems requires models that accurately represent real systems. Proper implementation of the designed model and evaluation of operational strategies, such as relatively advanced control algorithms and the selection of suitable alternatives, are among the existing challenges. These models often rely on real measurements of inflows, effluents, and key process indicators.

The best approach for optimizing wastewater treatment systems is to combine process and environmental methods, such as effluent quality and energy consumption. However, challenges persist, including the formulation of strategies for periodic shutdowns for maintenance, population growth, changes in inflow rates, and the presence of new pollutants. An appropriate strategy provides all the complex process tools needed for model calibration, sensitivity analysis, parameter estimation, process optimization, and energy minimization.

In essence, optimizing industrial wastewater treatment systems means implementing changes and improvements in design, operation, and related processes to maximize efficiency, cost-effectiveness, and environmental impact. Below, we delve into various aspects of wastewater treatment system optimization:

1. Optimal Design of Treatment Systems

Design is a critical stage in optimization. At this stage, factors such as the type of wastewater, chemical compositions, temperature, and volume must be considered.

– Selection of Appropriate Technologies: Depending on the type of pollutants, choosing between physical, chemical, and biological methods can significantly impact system performance. For example, biological reactors can be very effective for wastewater containing organic materials.

– Modeling and Simulation: Utilizing modeling software can assist designers in predicting system behavior and identifying its weaknesses. This facilitates design optimization and reduces operational costs.

2. Control and Monitoring of Parameters

Continuous control and monitoring of operational parameters can enhance system optimization:

– Monitoring Influent and Effluent Quality: By continuously measuring and analyzing the quality of influent and effluent, the efficiency of the system can be evaluated, and necessary actions can be taken if needed.

– Adjusting Operational Conditions: Modifying operational conditions such as temperature, pH, and retention time can improve treatment process efficiency. For instance, in biological systems, maintaining temperature and pH within optimal ranges can enhance microorganism growth.

3. Utilization of Advanced Technologies

Advanced technologies can contribute to optimizing treatment system performance:

– Nanotechnology: Nanomaterials can act as effective catalysts or adsorbents for removing pollutants from wastewater. This technology can improve treatment efficiency and help reduce side effects.

– Automated and Intelligent Systems: Implementing intelligent control and automation systems can minimize human errors and improve performance monitoring. These systems can automatically adjust operational conditions based on real-time data.

4. Cost Optimization

Cost optimization is one of the main objectives of treatment system enhancement:

– Reducing Operational Costs: By employing optimized methods, energy, chemical, and other resource consumption can be minimized. For example, utilizing energy recovery processes can help lower energy costs.

– Resource Management: Recovering and reusing resources from wastewater, such as water and chemicals, can lead to cost reduction and improved sustainability.

5. Compliance with Environmental Regulations

Optimizing treatment systems must align with environmental laws and regulations:

– Environmental Impact Assessment: Conducting environmental assessments is essential for identifying and mitigating the negative impacts of treatment systems on the environment.

– Reporting and Documentation: Accurate recording of data and treatment results can assist industries in adhering to environmental regulations and enable necessary improvements to their systems.

Optimization Through Expansion

A classical approach to optimization involves adding new tanks, which increases wastewater volume and results in more challenging effluent. This method is costly and requires significant space. A better solution is to optimize the operations and processes of existing wastewater treatment plants (WWTPs). In this approach, the increase in tank capacity can result in a threefold increase in efficiency.

Some Advantages of This Approach:

– Increased Capacity

– Reduced Pollutant Effluent

– Lower Energy and Chemical Consumption

WWTP Methods in Wastewater Treatment

Most controls, adjustments of processes, monitoring, and data collection in WWTP methods are performed automatically. This is achieved using fixed set points defined by operators for local control loops, such as dissolved oxygen and return sludge rate control. This type of automation leads to a significant increase in the efficiency of wastewater treatment.

Step-by-Step Optimization

In a typical optimization project, the first step is identification. The next stage involves identifying potential bottlenecks in daily operations. Creating a prioritized list of issues follows this. Actions taken to address or reduce inefficiencies may include:

– Modifications to the plant configuration, which may involve minor adjustments.

– Adding sensors and actuators (such as variable speed drives).

– Specifying the control set points that need to be implemented.

Estimating the outcomes of optimization actions in annual metrics may include:

– Savings in energy and chemical consumption.

– Reduction in effluent value – leading to lower effluent taxes.

– Increased capacity – postponing investment.

Simulation of Wastewater Treatment Systems

The simulation of wastewater systems is recognized as a key tool in water resource management and optimization of wastewater treatment processes. Given the increasing population and the growing demand for sanitation and environmental services, the use of simulation as an effective method for analyzing and designing wastewater management systems is essential. This article examines the principles, techniques, and applications of wastewater system simulation.

Principles of Simulation

Simulation refers to the creation of mathematical or computational models to mimic the actual behavior of systems. In the context of wastewater systems, these models can encompass physical, chemical, and biological processes occurring in wastewater treatment. The main stages in simulating wastewater systems include:

1. Defining Objectives: Establishing the goals of the simulation, such as optimizing system design, evaluating performance, or predicting system behavior under various conditions.

2. Modeling: Developing a mathematical model that describes the system’s behavior. This model may include differential equations, mass and energy balance equations, and other relationships.

3. Data Collection: Gathering empirical data to validate and refine the model.

4. Results Analysis: Examining the simulation outputs and comparing them with real data to assess model accuracy.

Simulation Techniques

Various techniques exist for simulating wastewater systems, including:

– Event-Driven Simulation: This method operates based on specific events occurring within the system and manages the time between these events.

– Monte Carlo Simulation: This approach uses random sampling to analyze uncertainties and predict system behavior.

– System Dynamics Modeling: This technique analyzes the relationships between components and variables of the system, examining temporal changes.

Applications of Simulation in Wastewater Systems

Simulation of wastewater systems has applications in various fields, including:

1. Design of Wastewater Treatment Plants: Simulation can assist engineers in creating optimized designs for treatment plants, thereby reducing costs.

2. Water Quality Management: Through simulation, the impacts of various factors on the effluent quality from treatment plants can be predicted, leading to better management strategies.

3. Climate Change Prediction: Simulating wastewater systems can help analyze the effects of climate change on the performance of wastewater systems.

4. Crisis Preparedness: By simulating different scenarios, improvements can be made in preparedness for crises such as floods or sudden contamination events.

Design and Simulation Software

In the design and simulation of industrial wastewater treatment systems, several specialized software tools can assist engineers and researchers in this field:

1. COMSOL Multiphysic

– COMSOL is a powerful tool for multiphysics modeling that can aid in simulating physical, chemical, and biological processes in wastewater treatment systems.

2. HYSYS

– HYSYS is another widely used software for simulating chemical processes and wastewater treatment, helping engineers model complex processes effectively.

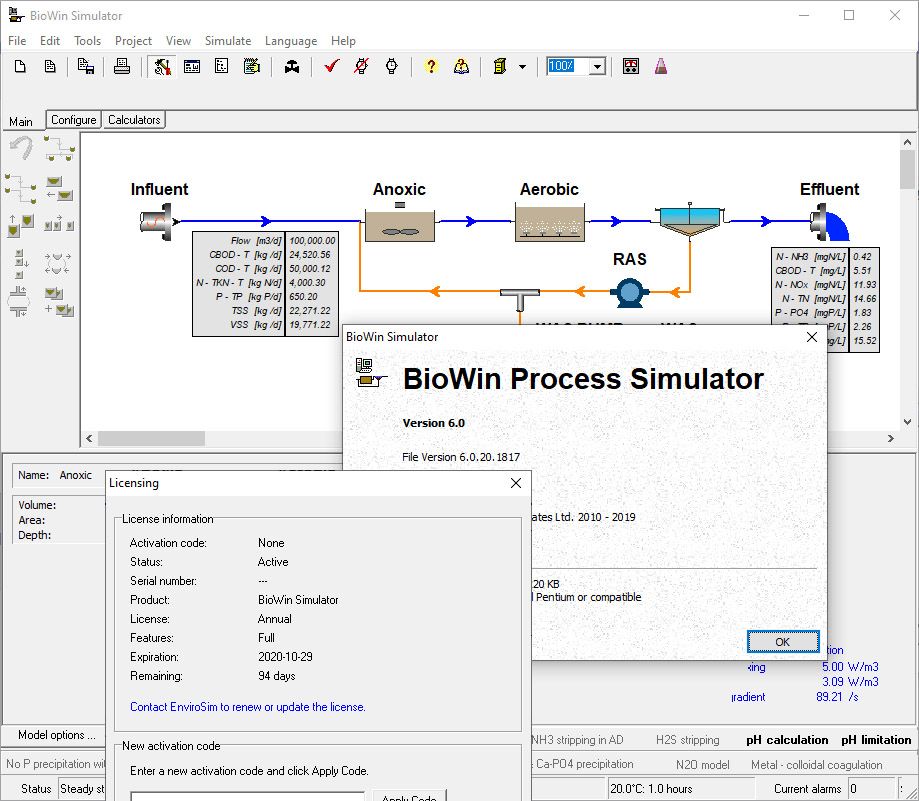

3. EnviroSim BioWin

EnviroSim BioWin is a specialized software for simulating the treatment processes of chemical and industrial wastewater, incorporating various models and methods of chemical, physical, and biological treatment. Using the BioWin wastewater treatment design software, which is tailored for chemical engineering, you can advancedly simulate biological, chemical, and physical processes in wastewater treatment and achieve your desired results.

When utilizing EnviroSim BioWin, you can simplify your simulations with the aid of various tables and charts for convenience and improved outcomes. The software also allows for the examination of water chemistry models to calculate pH, as well as mass transfer models for simulating oxygen and other gas-liquid reactions.

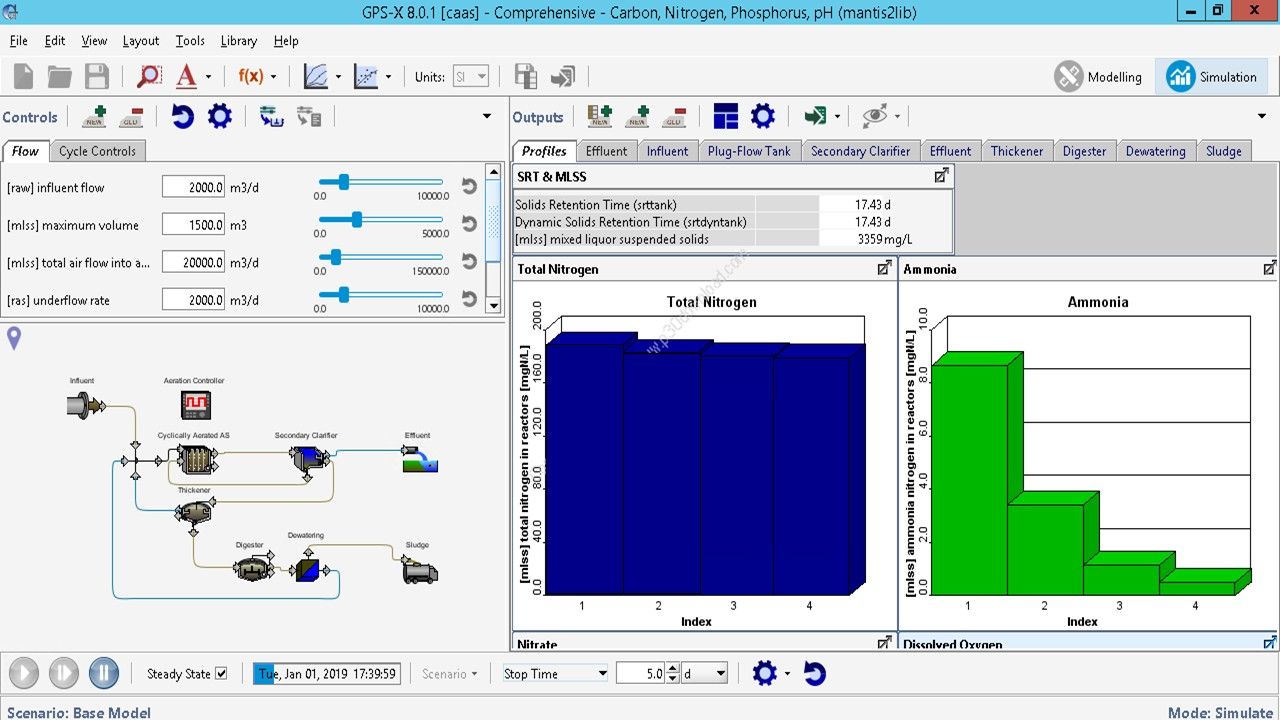

4. GPS-X Software

GPS-X is a comprehensive and powerful software for simulating, modeling, and analyzing wastewater treatment processes. This advanced tool is developed by Hydromantis Environmental Software Solutions, Inc. and is widely used in industry and scientific research. GPS-X enables users to dynamically and stably model complex biological, physical, and chemical treatment processes.

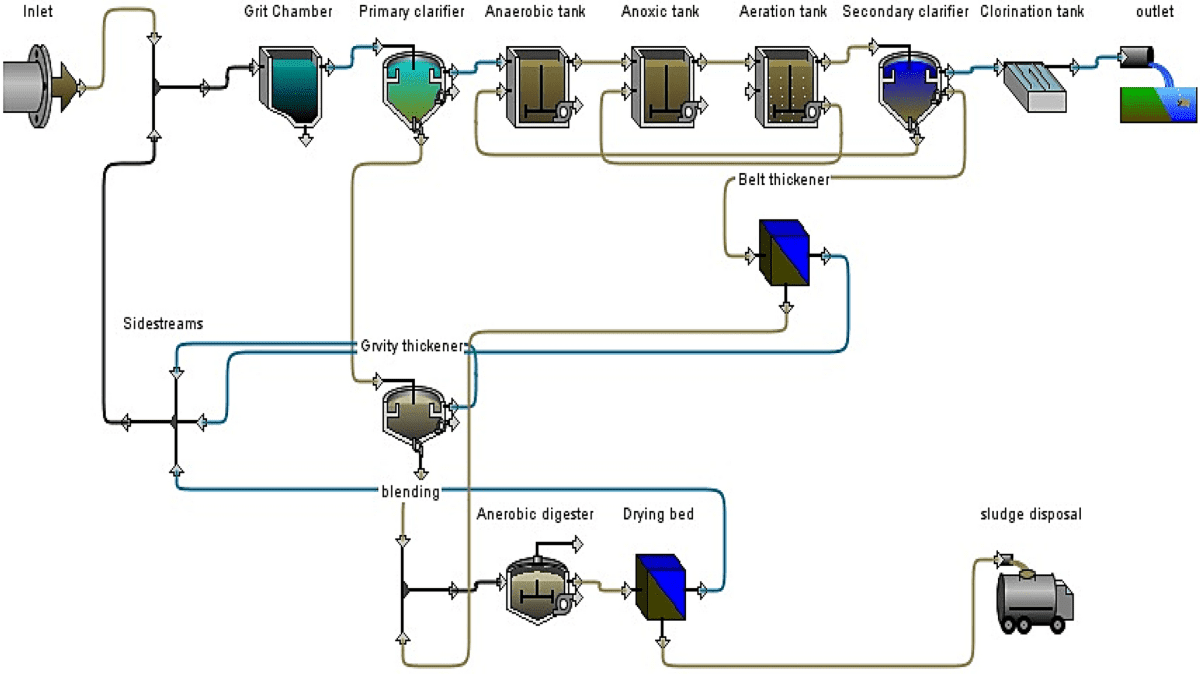

One of the key features of GPS-X is its high flexibility in designing and configuring processes. The software supports standard models such as ASM (Activated Sludge Models), allowing users to simulate various processes, including biological reactors, sedimentation, aeration, and filtration, with high detail.

By utilizing GPS-X, engineers can optimize the performance of treatment systems, identify potential issues, and provide cost-effective and sustainable solutions. Additionally, due to its user-friendly graphical interface and advanced analytical tools, the software is a popular choice among environmental professionals, students, and researchers.

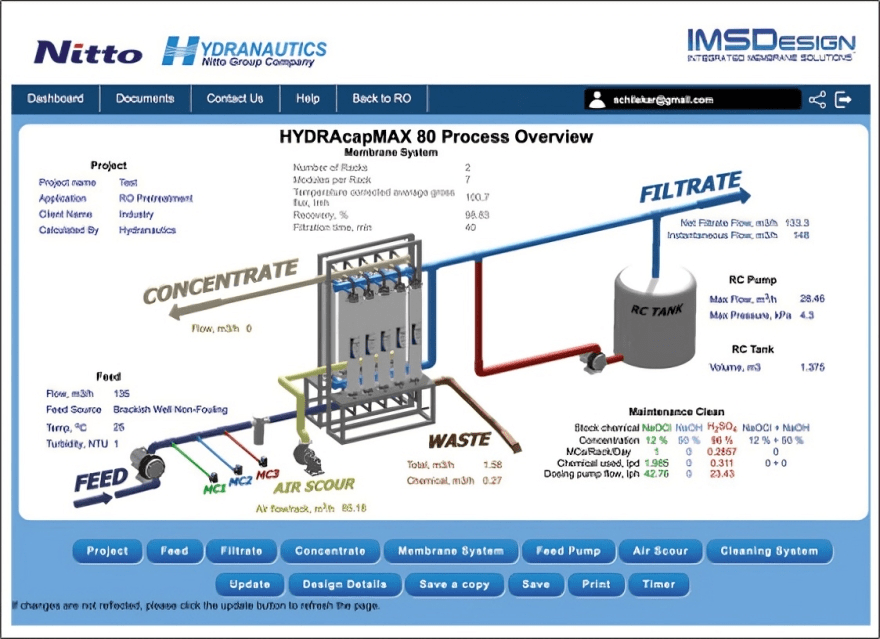

5. IMSDesign Software

IMSDesign is one of the most advanced engineering tools in the field of water and wastewater treatment, enabling industry professionals to design and simulate reverse osmosis (RO) systems with exceptional precision. Developed through the efforts of industrial experts and environmental engineers, this software has become an essential tool for optimizing treatment processes by providing accurate analyses and advanced capabilities.

Given the increasing importance of ensuring safe water supply and protecting the environment, the use of software like IMSDesign, capable of accurately simulating the behavior of treatment systems, is inevitable. This software assists engineers by allowing for detailed assessment of incoming and outgoing water quality, dynamic system simulation, and energy consumption optimization, leading to better design solutions for various applications.

Notable features of IMSDesign include an easy-to-use interface and deep data analysis capabilities, making it accessible even for novice users. By utilizing this software, design time and costs can be significantly reduced, resulting in higher efficiency of treatment systems.

Anil Pars Industrial Process Company

Anil Pars Industrial Process Company is one of the pioneers in the water and industrial wastewater treatment industry. Utilizing cutting-edge technologies and a skilled team of engineers and specialists, the company focuses on designing and constructing advanced water and wastewater treatment systems. The goal of this company is to provide innovative and efficient solutions for water resource management and reducing environmental pollution. Anil Pars Industrial Process Company assists its clients in achieving environmental standards while simultaneously reducing costs through the use of modern equipment and technologies.

In addition to designing and manufacturing treatment equipment, the company also offers consulting services in optimizing water and wastewater treatment processes. Considering the specific needs of each industry and various environmental conditions, Anil Pars Industrial Process Company provides customized solutions tailored to customer requirements. This approach enables the company to contribute to sustainable development goals and environmental preservation while improving the quality of consumable water and industrial wastewater.

Designed Units

Among the units designed by Anil Pars Industrial Process Company are the Coagulation Tank, A2O Biological Wastewater Treatment, Concentrator, Digester, Equalization Tank, Pump Station, Stripping Unit for VOC removal, and Bar Screen.

Designed Units

Among the units designed by Anil Pars Industrial Process Company are the Coagulation Tank, A2O Biological Wastewater Treatment, Concentrator, Digester, Equalization Tank, Pump Station, Stripping Unit for VOC removal, and Bar Screen.

Conclusion

Optimizing industrial wastewater management is a fundamental requirement in today’s industries. Anil Pars Company significantly contributes to achieving this goal by providing services in the design, optimization, and simulation of industrial wastewater systems. By utilizing modern techniques and advanced simulation software, we are capable of accurately analyzing processes and identifying existing deficiencies in wastewater systems. This approach allows us to offer optimal solutions for enhancing efficiency and reducing costs. Additionally, the three-dimensional design of systems helps us create precise and practical models that not only facilitate the design process but also increase reliability and compatibility with the specific needs of various industries.