Aspen Hysys Dynamic Software Training Course

مهر ۱۰, ۱۴۰۳

Matlab Training Course

مهر ۱۰, ۱۴۰۳Introducing ASpan Plus Software

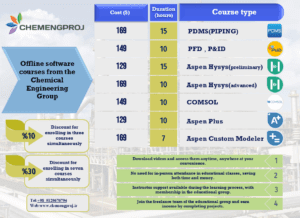

Due to the ever-increasing growth of chemical industries and oil, gas and petrochemical processes, the use of engineering software for simulating and evaluating units is inevitable. With the help of these simulator software, complex units such as refineries can also be modeled and simulated. Among the applications of aspen plus software in the industry, we can mention the design, development, improvement of operating conditions and optimization of petrochemical and refinery processes. One of the most important and comprehensive software in this field is Aspen Plus software, which solves most of the needs of chemical engineers.

Aspen Plus software is a product of the AspenTech software company, which is presented in a comprehensive and complete set called AspenOne. In addition to Aspen Plus, this collection includes other engineering software such as Hysys, Aspen Basic Engineering, Exchanger Design and Rating, etc.

The strength of Aspen Plus software compared to other simulation software is the strong database of this software in the field of physical and chemical properties of solids, liquids and gases.

Also, the possibility of designing and simulating polymer process units and solid material processes is another feature that distinguishes ASpan Plus from other software. ASpan Plus software has comprehensive and complete thermodynamic packages that predict material properties and process characteristics with high accuracy.

Also, with this software, you can model and simulate all the process equipment in the processes related to the oil and gas industries. In general, Aspen Plus is one of the most comprehensive and essential chemical engineering software.

Abilities of ASpan Plus Software

1. High accuracy and speed in calculating the most complex problems of chemical processes

2. Support for most oil, gas, petrochemical, electrolytic, pharmaceutical and…

3. Accurate and advanced design of process equipment such as towers, reactors, heat exchangers and…

4. Ability to simulate polymer processes

5. Ability to simulate processes related to solid materials

6. The possibility of simulating non-ideal equipment and processes

7. The possibility of simulating the process in a stable and dynamic way

8. The possibility of changing the operational conditions and parameters of the process and improving them

9. The possibility of analyzing different parameters of the process by different charts and optimizing those parameters

10. The possibility of coding in all parts of the software using the Fortran programming language

Get more information

Get more information