Introduction

The global consumption of natural gas is increasing day by day. Natural gas along with its acidic factors such as hydrogen sulfide (H2S) and carbon dioxide (CO2) in different concentrations is called sour gas. If these acidic factors are not removed, significant damages will be caused to the transmission lines and gas consuming equipment due to the corrosion process. Most sour gas is extracted from natural gas fields, and the process of removing acidic factors from it is called gas sweetening.

Natural gas sweetening means using a chemical or physical process to absorb acidic agents from the gas flow. Nowadays, process simulation is used to increase the accuracy of calculations and perform them in the shortest possible time, reduce production costs and optimize the process.

Description of the Process

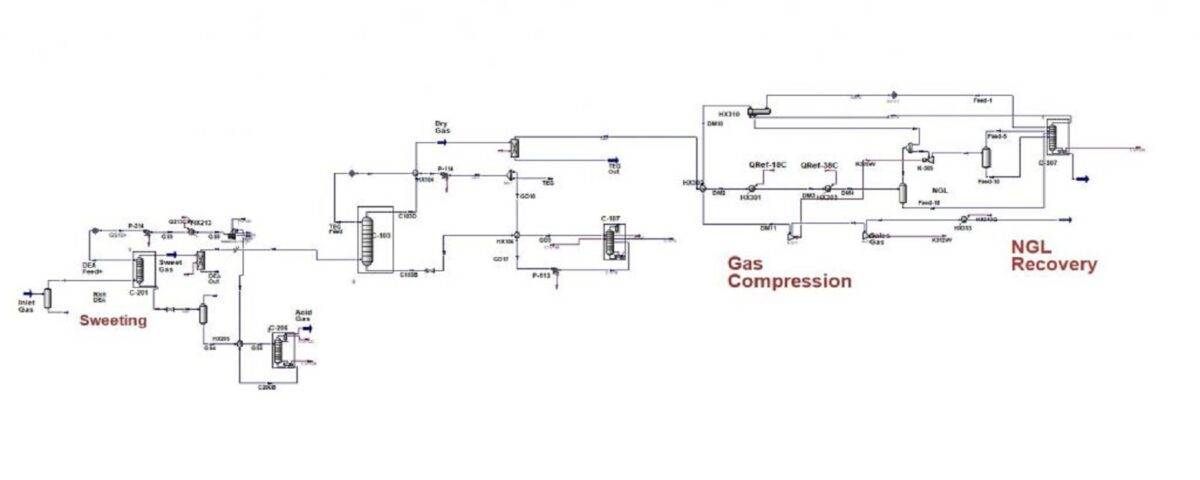

The simulation of the gas sweetening, compression, and recovery units is a complex, multi-stage process designed to optimize system performance and enhance productivity. This process begins with the collection of input data, including the natural gas composition, temperature, pressure, and physical properties of the fluids involved.

Next, advanced simulation software is utilized to accurately model the behavior of the gas during the various stages of sweetening and compression. This stage involves the application of equations of state and equilibrium models to predict the performance of the units and manage key process milestones.

Following this, the simulation results are analyzed, and necessary optimization processes are implemented to improve operational conditions. Special attention is given to aspects of natural gas recovery and the prevention of losses, ensuring the system operates efficiently and sustainably.

In this project, sour gas sweetening is simulated using Aspen HYSYS software. Then the simulation of compression and recovery processes has been done.

Conclusion

The conclusion drawn from the simulation of gas sweetening, compression, and recovery units highlights the significance of this process in enhancing efficiency and reducing costs. By utilizing advanced simulation techniques, engineers are able to accurately analyze the behavior of natural gas under various operating conditions and make more informed decisions regarding system optimization. This approach not only contributes to increasing the efficiency of the units but also helps mitigate the negative environmental impacts associated with resource loss and potential pollution.