Introduction

Desalination is a process that removes salts and minerals from seawater to produce fresh water. This process is particularly important in regions with limited freshwater resources. Let’s explore some of the most common desalination methods:

Thermal Processes (Distillation)

- Multi-Stage Flash Distillation (MSF): In this method, seawater is heated, producing vapor that is collected and condensed into fresh water.

- Multiple-Effect Distillation (MED): Similar to MSF, but the vapor produced in one stage is used to heat seawater in the next stage, improving energy efficiency.

- Vapor Compression Distillation (VCD): The produced vapor is compressed, increasing its temperature, and then used to evaporate seawater.

Membrane Processes

- Reverse Osmosis (RO): Seawater is forced through a semipermeable membrane. Water molecules pass through, while larger salt and mineral ions are retained.

- Nanofiltration: Similar to RO, but with larger pore sizes in the membrane, allowing some organic molecules to pass through in addition to salt.

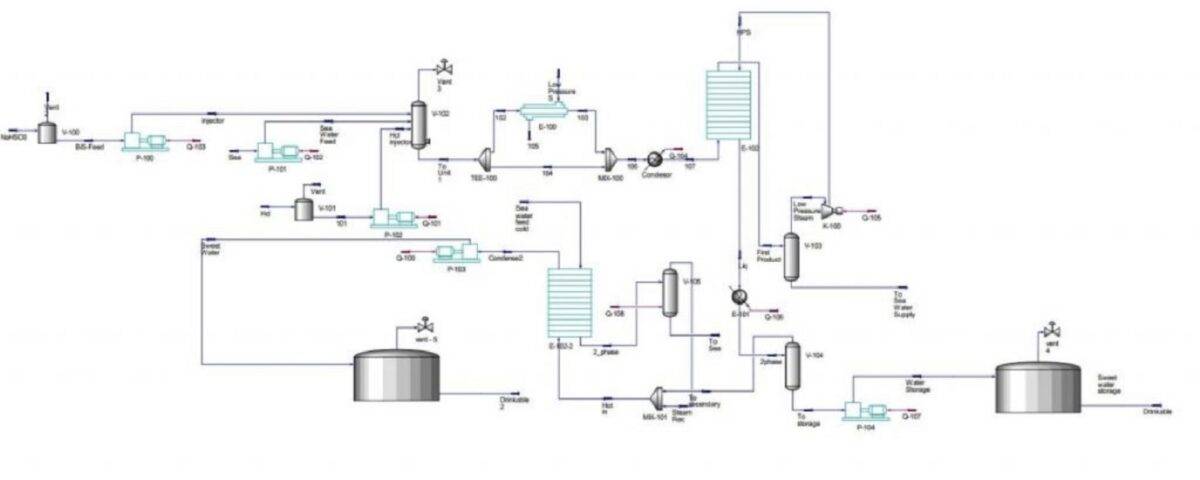

Multi-Stage Flash (MSF) distillation is a widely used and long-established method for desalination of seawater. This process leverages the principle of rapid vaporization or “flashing” that occurs when pressurized water is suddenly released into a lower pressure environment. MSF plants worldwide desalinate anywhere between 50,000 to 60,000 cubic meters of seawater daily using thermal energy.

The process begins by heating seawater to temperatures between 90°C and 120°C. This heated water then enters a series of chambers where pressure is successively reduced. The sudden drop in pressure causes a portion of the water to rapidly evaporate, a phenomenon known as flashing. The resulting vapor is then condensed on heat exchanger tubes, producing fresh water. This process is repeated multiple times, with each stage operating at a lower pressure than the preceding one. Typically, MSF plants have between 4 and 40 stages.

In this project, where the economic calculations of the sea salt water distillation unit have been done (plant design and economy project) and it also has the Aspen hysys simulation file, the economic calculations, equipment prices, profit-impurity and TCI tables have been calculated and are completely ready. (The text file is 37 pages of word).