Introduction

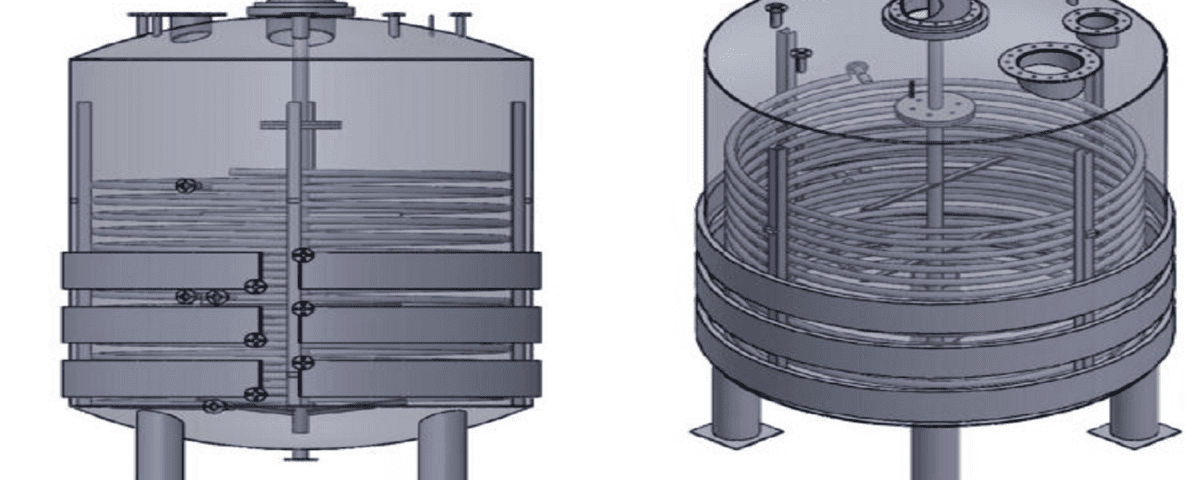

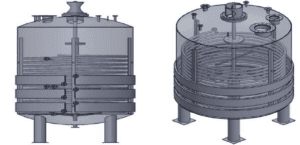

In industrial settings, large-capacity blenders play a crucial role in various production processes. They are particularly essential in chemical, pharmaceutical, food, and cosmetics industries, where precise mixing, heating, and cooling are required. This project focused on designing a 10000-liter blender, which includes a three-piece jacket, coil, and a two-piece vertical mixer, all constructed from S.S 316L stainless steel. This blender’s robust design and high resistance to corrosion make it ideal for diverse chemical reactions and mixing applications.

Project Objective

The goal was to create a detailed design of a 10,000-liter blender capable of handling intense chemical processes with features that enhance its mixing efficiency and heat exchange capabilities. Additionally, the project sought to provide the end-users with comprehensive manufacturing documentation and 3D modeling files. The completed files include:

- Body Drawing

- 3D View

- Mixer Drawing

- Nuzzle Orientation Layout

These documents were created in AutoCAD, with additional 3D files provided in SolidWorks format.

Materials and Specifications

The blender was constructed using Stainless Steel 316L due to its excellent corrosion resistance and suitability for handling both acidic and basic chemicals. S.S 316L also withstands high temperatures and maintains structural integrity in corrosive environments, making it ideal for the blender’s intended application in a paint and resin unit.

Key Material Advantages:

- Corrosion Resistance: S.S 316L resists various chemicals, including acidic compounds, making it suitable for aggressive environments.

- Durability: With enhanced strength and resistance to deformation under high pressure and temperature, S.S 316L ensures longevity.

- Sanitation: Its easy-to-clean nature is crucial for preventing contamination, especially in industries requiring high purity.

Blender Features and Components

- Three-Piece Jacket

The three-piece jacket encircles the blender’s body, providing controlled heating or cooling to maintain the desired temperature for chemical reactions. With the inclusion of multiple sections, the jacket allows for:- Efficient Heat Exchange: Distributed heating/cooling zones help maintain uniform temperatures.

- Flexible Temperature Control: Multiple sections allow specific areas to be heated or cooled based on the reaction needs.

- Internal Coil

The coil installed within the blender provides an additional method for temperature regulation by circulating a heating or cooling fluid through its network. The coil system offers:- Increased Surface Area: Maximizes heat transfer with the blending contents.

- Controlled Reaction Environment: Ensures consistent conditions for exothermic or endothermic reactions.

- Two-Piece Vertical Mixer

The vertical mixer consists of two sections that work in tandem to enhance the blending process. Each section is designed to create different flow patterns, improving homogeneity:- Upper Mixer Section: Distributes materials from the top, pushing them downward.

- Lower Mixer Section: Circulates materials upwards, preventing sedimentation and ensuring an even blend.

Design Documentation

All the design aspects were meticulously documented to guide the manufacturing process and facilitate future maintenance or replication efforts. The project deliverables include:

- Body Drawing: Detailed schematics of the blender’s main body, with dimensions and specifications of material thickness, structural support, and attachment points.

- 3D View: A comprehensive 3D model providing a realistic visual representation of the blender.

- Mixer Drawing: Detailed diagrams illustrating the mixer’s components, blade configurations, and dimensions.

- Nuzzle Orientation Layout: Layout showing nozzle placements for fluid and ingredient inlets and outlets, as well as ports for cleaning and monitoring.

All documentation is created in AutoCAD, with 3D files available in SolidWorks for enhanced visualization and adjustments.

Manufacturing Process

The blender was manufactured and assembled in 2019 at an industrial site specializing in paint and resin production, located in Shiraz Industrial Park. During production, quality control was strictly monitored to ensure compliance with industry standards.

Manufacturing Steps:

- Cutting and Forming: Stainless steel sheets were cut and formed to precise dimensions.

- Welding and Assembly: High-quality welding techniques were used to assemble the blender’s body, jacket, and internal coil.

- Polishing and Finishing: Surface polishing to enhance corrosion resistance and sanitation.

- Inspection and Testing: Pressure and leak tests were conducted on the jacket, coil, and blender body.

Installation and Operation

Once manufactured, the blender was transported to the Shiraz Industrial Park, where it was installed in a paint and resin processing facility. Key aspects of the installation included:

- Safety Protocols: Installation was conducted with strict adherence to safety guidelines, considering the high capacity of the blender and potential hazards related to chemical reactions.

- Operational Testing: Tests were conducted to confirm the operational efficiency of the mixer, jacket, and coil under simulated production conditions.

- Routine Maintenance: Maintenance schedules were established to ensure ongoing functionality and optimal performance.

Applications and Advantages

This 10,000-liter blender is versatile and can be used in a variety of industries that require robust mixing solutions, including:

- Chemical Industry: For mixing aggressive chemicals, polymers, and solutions requiring strict temperature control.

- Paint and Resin Production: Particularly suited for blending resins, additives, and solvents in paint production.

- Food Processing: Can handle viscous food ingredients, with its stainless steel construction preventing contamination.

- Pharmaceuticals: Suitable for the manufacture of bulk pharmaceuticals requiring sterile, controlled environments.

Advantages of the Blender:

- Uniform Mixing: The two-piece vertical mixer prevents sedimentation, ensuring homogeneous mixing.

- Controlled Reaction Environment: Jacket and coil system allow precise temperature regulation, essential for exothermic/endothermic reactions.

- Durability and Hygiene: Constructed from S.S 316L, ensuring longevity, easy cleaning, and prevention of contamination.

Conclusion

This project showcases the detailed design and manufacturing processes for a high-capacity, corrosion-resistant blender specifically tailored to the needs of the chemical and paint industries. The inclusion of a multi-piece jacket, coil, and two-piece vertical mixer optimizes the blender for controlled, large-scale chemical reactions.

By providing extensive design documentation and a comprehensive 3D model, the project ensures that end-users have a clear understanding of the blender’s operation and maintenance requirements. This blender represents a valuable asset for any facility in need of robust mixing capabilities for a range of applications, from paint production to chemical synthesis.

Future Improvements

Potential improvements for future iterations of the blender design could include:

- Automated Control Systems: Integrating automation for real-time monitoring and adjustment of temperature and mixing speeds.

- Enhanced Mixer Design: Testing alternative blade designs to improve mixing efficiency for specific applications.

- Energy Efficiency: Investigating insulation options to minimize heat loss in the jacket and coil systems, improving energy efficiency.

This 10,000-liter blender design project exemplifies advanced engineering solutions in industrial mixing, offering flexibility, durability, and high performance for complex chemical processes.