Introduction

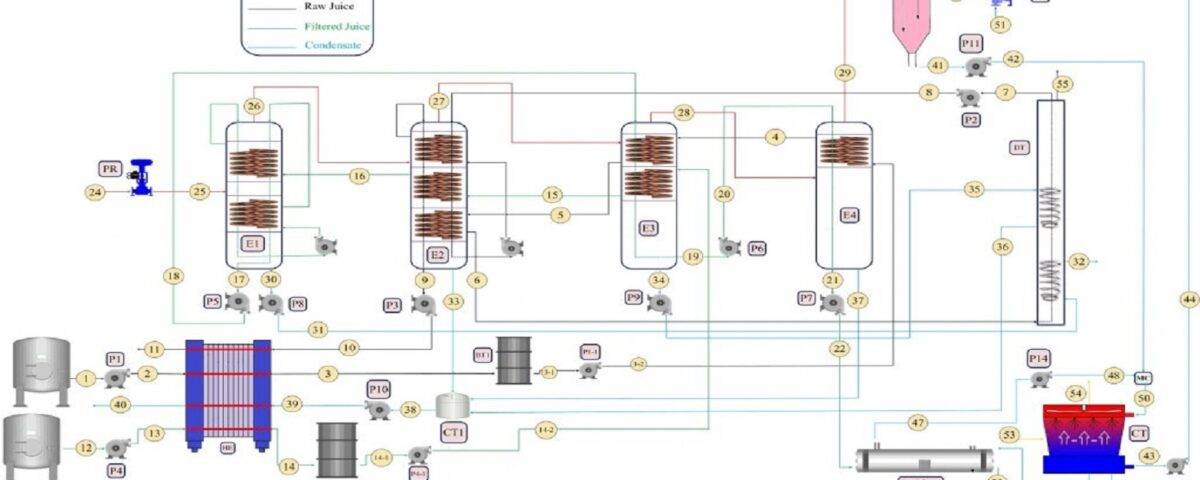

The fruit concentrate production line in this company consists of four stages of falling film evaporator, the energy needed for the first stage is provided by steam and the steam output from each stage is used to provide the energy needed for the next stages. The process flow map of this process can be seen in the figure above.

Fruit Concentrate Production Process

In this process, the incoming fruit juice is preheated using a plate heat exchanger (HE) by utilizing the energy available in the condensates and the heat of the outgoing raw fruit juice. After the HE, the incoming fruit juice undergoes a three-stage preheating process in evaporators E2, E3, and E4. Subsequently, to separate the aroma, it enters the distillation tower DT. After aroma separation, the fruit juice undergoes two stages of concentration in evaporator E2. After cooling in the HE for filtration, it exits the line. The steam generated during the concentration of fruit juice in E2 is used for concentration in E3.

After filtration, the fruit juice is returned to the concentration line to be preheated by the HE. Then, it undergoes two stages of preheating in E3 and E2 for concentration in E1. The energy required for evaporation in E1 is supplied by the steam entering the concentration line. The steam generated in E1 is used to supply energy to E2 and The concentrated fruit juice from E1 comes into contact with the steam generated from E2 in evaporator E3 and is concentrated again. In the final stage, the fruit juice is concentrated in evaporator E4 to the desired concentration. Finally, it is cooled by the cooling water in the heat exchanger JC and exits the concentration line. The cold water required for cooling the fruit juice is supplied by the barometric cooling tower.

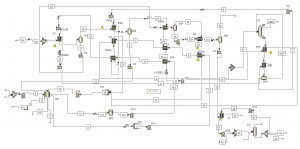

The figure below shows the simulation of the process with Aspen Plus software.

Heat Exchanger Network and Pinch Analysis

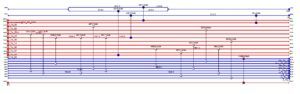

Since the only energy input to this process is the main steam, and the goal is to heat the incoming fruit juice, operational parameters have a limited impact on energy reduction. The best way to reduce energy consumption is to optimally utilize the available energy in the process to effectively heat the fruit juice. Therefore, the best solution to reduce energy consumption is to modify the existing heat exchanger network in the process. By performing pinch analysis on the current heat exchanger network, the performance of the process can be determined.

Heat Exchanger Network

As shown in the figure above, the red lines represent hot process streams that need to be cooled, while the blue lines represent cold process streams that need to be heated. Process heat exchangers are marked with white circles, water-cooled heat exchangers with blue circles, and steam-heated heat exchangers with red circles.

This project, in addition to simulation files and heat exchanger network design, includes a comprehensive report and a training video.