Introduction

Project management and engineering document control in the production units of MEG (Monoethylene Glycol), DEG (Diethylene Glycol), and TEG (Triethylene Glycol) are key factors for the success of these industrial processes. In today’s complex and competitive environment, the precise and effective execution of projects, adhering to technical requirements and quality standards, not only enhances productivity and reduces costs but also fosters trust among stakeholders and customers. These processes involve planning, collecting, evaluating engineering documents, and ultimately approving and establishing technical documentation that serves as the basis for decision-making and project guidance. Thus, establishing a systematic and transparent document management system is critical for achieving project goals and ensuring product quality in chemical units.

This management system can be enhanced using digital tools and project management software, enabling easy tracking of changes, monitoring timelines, and updating documents. Additionally, continuous and effective communication among various teams, including engineers, managers, and contractors, aids in the rapid and efficient exchange of information, preventing errors and misalignments.

Attention to risk management principles is also essential in these processes; identifying and assessing potential risks can ensure that document control is conducted with a preventive approach. Furthermore, focusing on training and empowering various teams will lead to improved work quality and better overall project outcomes.

Project Management

Project management is an organized approach to planning, executing, and controlling projects, particularly in the fields of engineering and industry, and is of special importance. In projects related to the production units of MEG, DEG, and TEG, project management is divided into various stages, each playing a vital role in achieving project objectives.

– Planning: The first step in project management is thorough planning, which includes identifying project goals, defining timelines, allocating necessary resources, and planning tasks. Establishing success criteria and precise timelines ensures that all team members work towards a shared goal and can easily manage potential changes.

– Project Execution: After planning, the project execution begins. This phase involves carrying out activities and tasks according to the previous plan. During this part, teams must coordinate and collaborate closely to ensure that work proceeds as planned. Human and financial resource management is crucial at this stage, as any inefficiency or errors can lead to project delays and increased costs.

– Monitoring and Control: Monitoring and controlling are key components of project management that ensure the validity of planning and execution. At this stage, continuous monitoring of project progress and examining deviations from the timeline and budget occurs. Additionally, identifying and managing potential risks during this process play an important role in guiding the project towards its established goals. Utilizing analytical and reporting tools enables project managers to quickly implement necessary changes and make informed decisions regarding project performance optimization.

Ultimately, project management is an interactive process that requires precise coordination among all teams and stakeholders; as success in engineering projects, particularly in complex industries like MEG, DEG, and TEG production, necessitates a comprehensive and coordinated approach.

Engineering Document Control

Engineering document control is a vital process in managing engineering projects, ensuring the accuracy and quality of information used at various stages of the project. This process includes the collection, registration, review, and approval of essential documents for the project, which may encompass designs, drawings, technical specifications, and relevant standards. Document control not only contributes to discipline within the project but can also prevent costly errors and issues in the future. This process can be divided as follows:

– Document Registration and Receipt: The first step in document control is accurately registering and receiving project-related documents. Each document pertinent to the project must be collected and documented in a centralized registration system. This action includes logging key details such as reception dates, names of providers, and document types. With a well-organized database, quick access to documents and tracking of changes and various versions become possible.

– Technical Review: Following document registration, the technical review stage begins. At this point, documents must be technically assessed to ensure that they comply with project standards and requirements. This review includes evaluating technical details, consistency with preliminary documents, and validating designs and drawings. This stage aids in identifying any weaknesses or deficiencies in the documents and prevents problems that may arise in later execution phases.

– Final Approval: After completing the necessary reviews, documents must be approved for implementation. This final approval involves a formal process where the documents, following necessary review and revisions, are confirmed by experienced personnel and project managers. This approval is essential to assure that all documents used in the project have the necessary quality and accuracy, allowing the execution team to utilize them without concern.

Endorsement

Endorsement in the context of project management for the production units of MEG, DEG, and TEG is recognized as a key step in validating and approving engineering documents. This process includes the review and endorsement of technical documents, designs, and drawings by qualified experts and authorities with adequate knowledge and experience in this field. The aim of endorsement is to ensure that documents comply with necessary standards and project requirements to guarantee quality and accuracy during the implementation phases. This validation helps mitigate risks associated with errors and non-compliance, ultimately boosting stakeholders’ confidence in the project. Through the endorsement process, the credibility of documents and technical details is confirmed, leading to improved overall project performance and successful glycol product production.

Importance of Document Control and Endorsement

Document control and their endorsement are highly significant for the success of engineering projects, playing a critical role in preventing errors during execution and design phases. By executing these processes, document compliance with standards and project requirements is effectively guaranteed, thereby minimizing the potential for costly and time-consuming errors and deficiencies. Additionally, document control and endorsement greatly enhance transparency and clarity in communications among the various project teams.

With a clear and organized system for collecting, registering, and approving documents, all team members benefit from accurate and up-to-date information, which reduces ambiguity and strengthens collaboration within the team. This mutual trust and cooperation among different groups help improve decision-making processes and enhance team efficiency and productivity. Overall, document control and approval processes not only help prevent errors but also lead to improved final project quality and create a positive atmosphere for collaboration, ultimately resulting in the overall success of the project.

Project Management and Engineering Document Control in Glycol Production

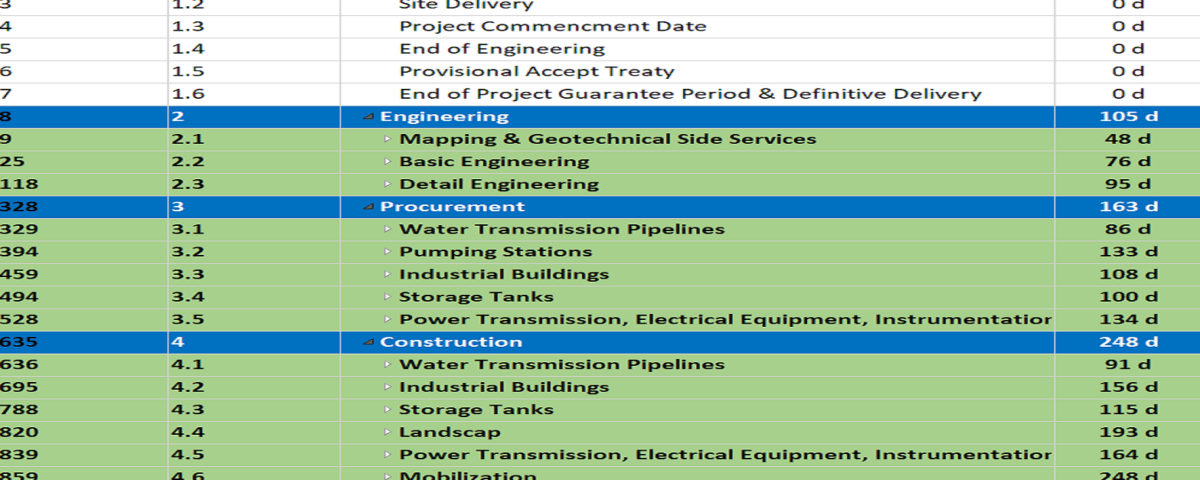

The process of project management and engineering document control in the production units of MEG, DEG, and TEG includes critical stages that ensure project success and optimal performance. Initially, the project team prepares a comprehensive roadmap for project execution through thorough planning and identifying objectives, timelines, and resources required. In this phase, task allocation among team members is conducted. Subsequently, with the commencement of project execution, all activities are performed based on the planned schedule, with ongoing monitoring and controls to ensure progress aligns with specified timelines and budgets.

Alongside these aspects, engineering document control is also an essential part of the process, involving the registration, review, and approval of crucial documents such as designs, drawings, and technical specifications. These documents must be technically evaluated to ensure their compliance with project standards and requirements. Ultimately, formal approval of the documents by management and stakeholders is necessary to prevent errors during execution and ensure that the production process progresses smoothly and effectively. By adhering to these processes, the highest levels of efficiency and success can be achieved in glycol production.

After document approval and confirming their quality and compliance with project requirements, the project team must move to the implementation and production phase. At this stage, workers and engineers start their operational activities using the approved information, executing designs and technical specifications. The project management team continues to oversee and control progress while employing modeling and simulation techniques to identify and manage potential issues.

Throughout the production process, continuous feedback from employees and engineers impacts project performance, and any deviations from the initial plan must be promptly identified and addressed. Effective communication among team members aids in facilitating this process, and using digital tools and project management software can optimize the management of documents and project-related data.

Finally, upon completion of the project, a final review and evaluation are conducted to assess the project’s success in meeting initial goals and fulfilling customer expectations. This evaluation may include lessons learned from successes and challenges that will inform the improvement of similar future project processes. Thus, project management and engineering document control not only lead to successful project outcomes but also contribute to enhancing quality and production standards within the glycol industry.

Foresight in the MEG, DEG, and TEG Production Industry

Foresight in the MEG, DEG, and TEG production industry is a crucial component of the strategy for developing these industries, helping to identify and predict future trends and key market developments. Given the rapid technological changes, increased demand for sustainable and environmentally friendly products, and global economic pressures, glycol industries must leverage digital innovations, automation, and green technologies to maintain their competitive edge. This process involves developing new technologies in production, optimizing processes, reducing costs, and enhancing energy efficiency while minimizing environmental impacts.

Moreover, investing in research and development to create new products and improve existing processes is essential. With market uncertainties and the growing need for compliance with governing regulations, industries must continuously update and innovate to meet evolving customer needs. By adopting these strategies, MEG, DEG, and TEG production industries can advance sustainably in both economic and environmental aspects.

Additionally, in response to the increasing emphasis on sustainability and reducing negative environmental impacts, the MEG, DEG, and TEG production industry must advance towards using renewable raw materials and decarbonization processes. These changes not only help enhance brand image but can also attract new investments and establish strategic partnerships with innovative companies in environmental fields.

Another critical point in the foresight of this industry is analyzing global markets and identifying new export opportunities. With rising demand for clean products in various countries, the glycol industry must seek new markets and create effective distribution networks to increase its share in international markets. Furthermore, understanding customer needs and maintaining relationships with them should be prioritized in business decision-making.

To keep pace with market changes, fostering intrapreneurial innovation and collaborating with universities and research centers is also of great importance. These collaborations can accelerate the development of new technologies, products, and optimized processes.

Conclusion

Effective project management, precise engineering document control, and endorsement processes are key factors in achieving success in the production of MEG, DEG, and TEG. These chemical products, due to their extensive applications across various industries, require high precision and quality at every stage of the production process. Given the specific sensitivities of these processes, adhering to standards and best practices for document control and endorsement is essential, as any defect or error can have serious repercussions on the final product’s quality and customer satisfaction.

Implementing these stages meticulously and systematically directly impacts productivity and reduces unnecessary costs, allowing project teams to achieve their objectives with greater confidence. Additionally, this approach can enhance internal communications and improve transparency in project activities. Therefore, focusing on the details of project management and document control systems not only raises the quality of chemical product production but also fosters a culture of collaboration and trust within teams, ultimately leading to greater long-term success.

To enhance performance and productivity in the design, establishment, production of technical knowledge, innovative engineering, and optimization of glycol production and purification units in Saudi Arabia, Chemengproj Company has undertaken comprehensive simulation and optimization studies on the key processes of this unit. These studies include the following:

1. Feasibility study of the separation and purification unit of glycols with a capacity of 15 KTY.

2. Production of basic engineering documents; Operation Manual for the glycol unit.

3. Performance analysis of production and resource management at the Arta Chemical plant: evaluation of performance reports, human resources, and raw materials.

4. Establishment plan and technical knowledge for producing MEG, DEG, and TEG with a capacity of 15 KTY.

5. Design of documents, technical knowledge, and drawings for BFD, PFD, PID, and UFD of the glycol purification unit.

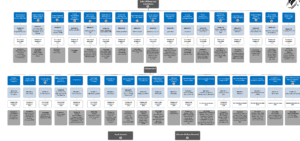

6. Management, control, and endorsement of engineering documents for the production unit of MEG, DEG, and TEG.

7. Simulation and optimization of the Monoethylene Glycol (MEG) purification process with a production capacity of 10 KTY.

8. Simulation and optimization of the Monoethylene Glycol (MEG) purification process with a production capacity of 15 KTY.

These initiatives aim to enhance the production of technical knowledge and innovative engineering, reduce production costs, optimize glycol production processes, and design modern units. The ultimate goal is to ensure better product quality and increase the company’s competitiveness in the market.

Project Management, Control, and Endorsement of Engineering Documents for the Production Unit of MEG, DEG, and TEG

In this project, project management, control, and endorsement of engineering documents for the production unit of MEG, DEG, and TEG have been carried out.