Introduction

The purification process of Monoethylene Glycol (MEG) has gained increasing importance in various industries, particularly in the production of polyester fibers and polyethylene terephthalate resins. Due to its unique properties, including high solubility and suitable chemical characteristics, MEG is widely used in the formulation of diverse products. The production process of MEG typically involves converting ethylene to ethylene oxide (EO) and subsequently hydrolyzing it to MEG. Given the growing demands of the industry, there is a need for optimization to enhance efficiency and economic viability.

Furthermore, one of the key benefits of this new process is the significant reduction in carbon dioxide emissions, which aligns with environmental preservation and carbon compliance requirements across various industries. This, along with optimal energy resource utilization, underscores the strengths of these innovative methods in MEG production. Advanced simulation software, such as Aspen Plus, enables precise modeling of processes and economic assessments to identify and implement the best operational conditions for MEG production.

Consequently, companies in this field must continuously engage in research and development while adopting new technologies to outpace competitors, while also adhering to their environmental and social objectives. In light of these developments, the future of MEG production is leaning towards sustainable and reliable applications with an optimized process approach, aiding not only economic prosperity but also environmental conservation.

MEG Purification Process Overview

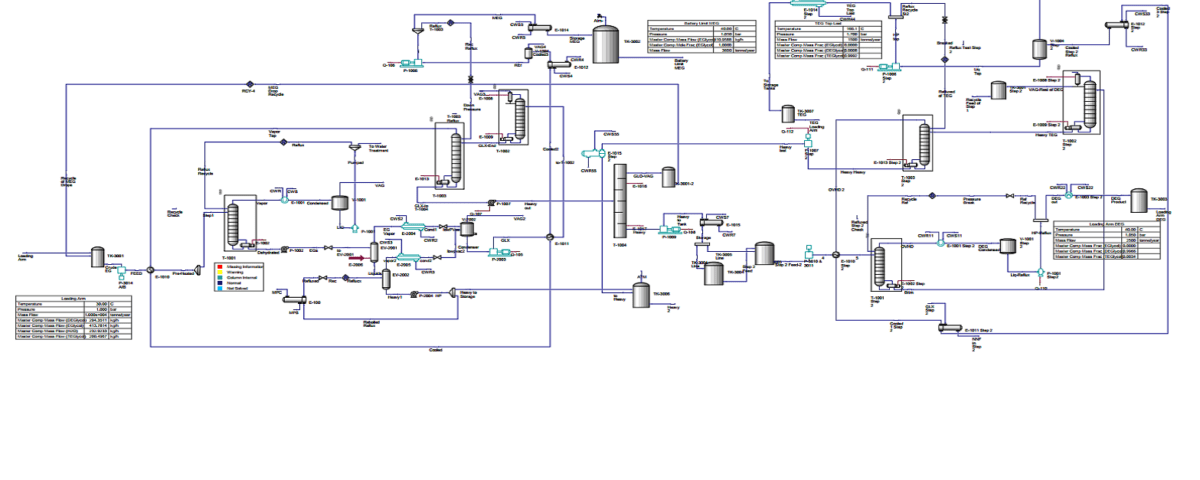

The purification process of Monoethylene Glycol (MEG) at the Petronad Asia petrochemical plant is particularly significant due to the growing demand for high-quality additives in the chemical industry. Each step is meticulously executed to optimize performance and enhance the quality of the final products.

Step 1: Water Absorption and MEG Purification

– Feed Entry: The primary feed, consisting of various chemicals, is transferred to the tank 310-TK-3001. If the feed contains substances like soda and sulfuric acid, these are neutralized to mitigate their potential destructive effects in subsequent stages.

– Preheating: The feed is preheated to provide necessary energy for the subsequent process and directed to column 310-T-1001, designed for water evaporation. In this column, water is vaporized, concentrating the glycol.

– Vapor Compression: The steam generated at this stage is routed to heat exchanger 310-E-1001, where the vapor is condensed and transferred to tank 310-V-1001 for the production of water and liquid glycols.

– Steam Return: Part of the distilled product is returned to the column to enhance the overall quality of the final products.

– Process Conditions: The pressure in column 310-T-1001 is maintained under vacuum at roughly 250 mbar to prevent the decomposition of sensitive compounds and ensure final quality.

Step 2: Purification of DEG and TEG

– Feed Entry: Heavy feed 1 extracted from tanks 310-TK-3005 and 310-TK-3004 is directed to heat exchanger 310-E-1010 for preheating to desired temperatures.

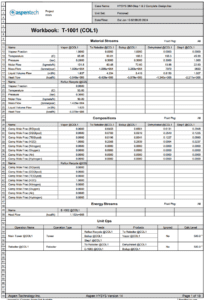

– DEG Purification: In this column, diethylene glycol purification occurs under specific temperature and pressure conditions, producing DEG with a purity of 99.6% by weight, widely used in the industry.

– TEG Distillation: Steam generated from the column is transferred to tank 310-V-1004, where triethylene glycol with a purity of 99.8% by weight is obtained. These raw materials not only serve as solvents in many processes but also as additives in the production of other chemical products.

Factors Affecting the MEG Purification Process

Several key factors influence the MEG purification process, optimizing performance and ensuring the quality of final products while guaranteeing economic and environmental efficiency in the petrochemical industry. These factors include:

– Temperature and Pressure Conditions: Operational temperature control, especially in distillation columns, is crucial to prevent material decomposition and maximize yield. While increased temperature can positively impact reaction rates, it is essential to avoid excessively high temperatures that may decompose sensitive compounds. Utilization of vacuum conditions (like 250 mbar) in columns aids in lowering boiling points and enhancing evaporation efficiency.

– Mass Return Ratio: The steam return ratio in distillation columns is vital for maintaining balance and enhancing the purity of final products. Returning steam encourages richer glycol vapors to re-enter the cycle, improving purity and production efficiency.

– Feed Quality: The presence of impurities such as soda and sulfuric acid can significantly impact the process, necessitating their neutralization prior to entry to prevent equipment damage and maintain product quality. The quality of the incoming feed also directly affects operational costs and equipment performance.

– Equipment Design: Proper design of distillation columns, including the number of trays and types of heat exchangers, significantly impacts separation efficiency and final product purity. An optimal design facilitates greater contact between vapor and liquid, enhancing product quality.

– Process Control: Automation systems for monitoring key parameters such as temperature, pressure, and flow rate can improve efficiency and reduce risks.

– Waste Management: Establishing recycling and treatment systems for byproducts not only aids in preserving natural resources but can significantly lower waste disposal costs and enhance compliance with environmental regulations.

Collectively, these factors affect the final quality of MEG and related products, necessitating careful monitoring throughout the purification process. Optimizing these considerations can lead to overall system performance improvements, cost reductions, and ultimately, higher-quality and more sustainable products. Effective understanding and management of these factors enhance competitiveness and sustainability for companies in global markets.

Production Costs of MEG in New Processes

The reduction of production costs for Monoethylene Glycol (MEG) in new processes relies on several factors that significantly optimize performance and cost efficiency. One of the most critical factors is process integration. In modern approaches, ethylene oxide (EO) and MEG production units are designed to be interconnected. This approach not only substantially reduces energy costs but also facilitates the recovery of high-value products from side streams, contributing to increased revenue and reduced waste.

– Catalyst Utilization: The use of new catalysts, such as MTO (Methyl Trioxonium), in EO production reactors significantly aids in cost reduction and increases reaction yields. These catalysts allow reactions to occur under more optimal conditions while minimizing the risk of unwanted side reactions that could affect product quality.

– Heat Management: Employing integrated thermal management tools can minimize heating and cooling energy requirements throughout the process, significantly reducing operational costs (OPEX) and mitigating environmental impacts due to reduced energy consumption and greenhouse gas emissions.

– Waste Management: Effective management of waste and maximizing product recovery from side streams play a vital role in cost reduction. As MEG production typically generates carbon dioxide and other pollutants, optimizing processes to reduce these emissions not only helps lower costs but also enhances environmental sustainability.

In conclusion, these combined factors ensure that new MEG production processes are not only more economical but also sustainable, effectively meeting the growing market demands.

Conclusion

In summary, optimizing the production processes of Monoethylene Glycol (MEG) as a key raw material in various industries requires attention to a set of influential factors that aid in cost reduction and performance improvement. Integrating EO and MEG production units, utilizing advanced catalysts, applying multi-tube reactors, managing heat intelligently, and effectively recovering waste materials are all strategies that can significantly decrease both capital (CAPEX) and operational (OPEX) costs.

These approaches contribute not only to increasing profitability and economic sustainability but also to positive environmental impacts. Given the ever-growing demand for MEG and the industry’s need for more sustainable processes, constant innovation and optimization in this sector become a necessity. Thus, it is expected that future MEG production processes will not only be more efficient but also more cost-effective and compatible with environmental requirements, ultimately facilitating market supply and supporting sustainable development.

To enhance performance and productivity in the design, establishment, production of technical knowledge, innovative engineering, and process optimization of glycol units in Saudi Arabia, Anil Pars Company has undertaken comprehensive simulation and optimization studies on the key processes of this unit. These studies include:

1. Feasibility study for the separation and purification unit of glycols with a capacity of 15 KTY.

2. Production of basic engineering documents; Operation Manual for the glycol unit.

3. Performance analysis of production and resource management at the Arta Chemical plant: evaluation of performance reports, human resources, and raw materials.

4. Establishment plan and technical knowledge for producing MEG, DEG, and TEG with a capacity of 15 KTY.

5. Design of documents, technical knowledge, and drawings for BFD, PFD, PID, and UFD of the glycol purification unit.

6. Project management, control, and endorsement of engineering documents for the MEG, DEG, and TEG production unit.

7. Simulation and optimization of the Monoethylene Glycol (MEG) purification process with a production capacity of 10 KTY.

8. Simulation and optimization of the Monoethylene Glycol (MEG) purification process with a production capacity of 15 KTY.

These actions aim to enhance the production of technical knowledge and innovative engineering, reduce production costs, optimize glycol manufacturing processes, and design modern units. The ultimate goal is to ensure better product quality and increase the company’s competitiveness in the market.

Simulation and Optimization of the Monoethylene Glycol (MEG) Purification Process with a Production Capacity of 10 KTY

In this project, the simulation and optimization of the Monoethylene Glycol (MEG) purification process with a production capacity of 10 KTY have been conducted.