Introduction

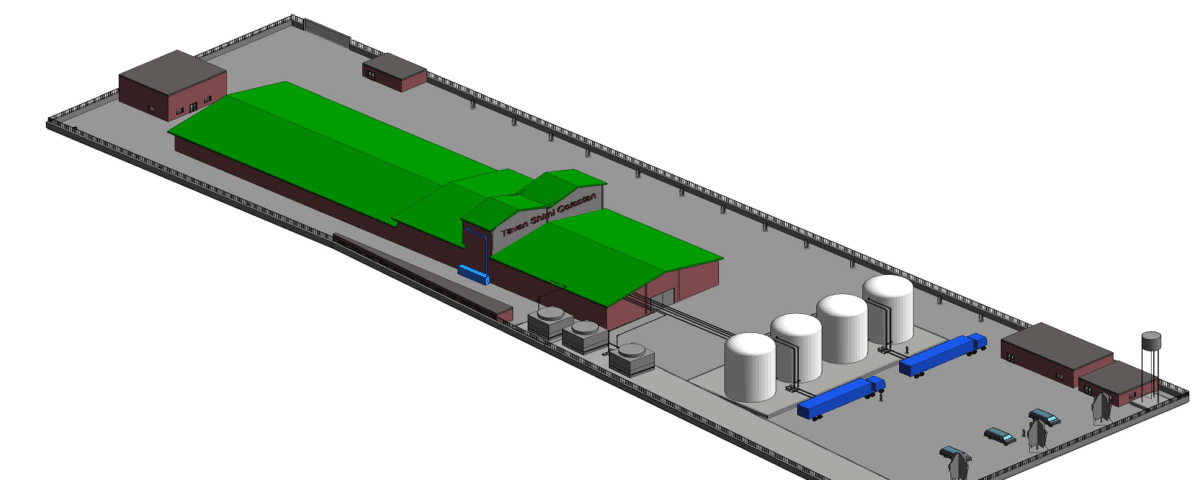

Given the growing importance of refined edible oils in the food industry, the design and implementation of edible oil refining units have become crucial. Edible oils, as a primary consumable in the food industry, require sophisticated processes for refining and purification to ensure high quality and safety. A well-designed refining unit plays a key role in enhancing the quality and efficiency of the final product. This project aims to create a 3D conceptual design for an edible oil refining unit, tailored to the client’s specifications.

Project Objectives

The main objective of this project was to develop a three-dimensional conceptual model of an edible oil refining unit that could visually and functionally meet the client’s needs. The design was created using Revit and PDMS software, providing an overall representation of the unit without detailed specifications, as the client requested only a schematic and aesthetic design.

Software Utilized

- Revit: This software is a powerful tool for architectural modeling and 3D visualization, enabling rapid and detailed design. It allows the creation of realistic models and layout drawings necessary for project documentation.

- PDMS (Plant Design Management System): PDMS is widely used in the design and management of large industrial projects. In this project, PDMS was employed to optimize the spatial arrangement of equipment and piping, ensuring efficient space utilization within the refining unit.

Project Stages

1. Initial Design and Client Requirement Analysis

The first stage involved analyzing the client’s requirements and understanding the essential components of the edible oil refining unit. By studying similar refining processes and gathering necessary data, the design team gained a clear overview of the project’s needs. Based on this analysis, an initial schematic layout was created in Revit.

2. Creating the 3D Model in Revit

The next stage focused on building a comprehensive 3D model in Revit, covering critical elements such as tanks, material transfer equipment, pipelines, and storage sections. Since this was a conceptual design, the focus was placed on aesthetics and overall layout, avoiding detailed technical specifications.

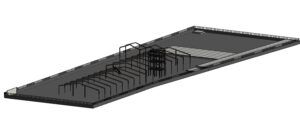

3. Spatial Arrangement Optimization with PDMS

After creating the basic model in Revit, PDMS was used to refine the layout of equipment and ensure practicality in the design. PDMS allows designers to fine-tune spatial arrangements, ensuring ease of movement and accessibility throughout the unit.

4. Producing Layout Drawings and Visual Outputs

At the end of the project, high-resolution layout drawings and 3D visualizations of the model were generated. These outputs include schematic layout plans and conceptual visuals, providing the client with a clear overview of the unit from various angles.

Benefits of Conceptual Design in Industrial Projects

- Cost and Time Efficiency: Conceptual designs, due to their lack of intricate details, generally require less time and budget to complete.

- Enhanced Space Utilization: Using 3D modeling tools allows for optimal spatial arrangements, giving clients a better understanding of the scale and potential functionality of the facility.

- Improved Decision-Making: A 3D conceptual design enables clients to make informed decisions and apply any necessary changes before moving into the detailed design and construction phases.

Key Elements in Designing an Edible Oil Refining Unit

An edible oil refining unit comprises several main stages that require careful planning and design for maximum efficiency. These stages typically include filtration, chemical processing, separation, and storage. Each of these sections has been represented schematically in the conceptual design, along with the primary equipment for each phase.

Revit’s Importance in 3D Industrial Design

Revit is an ideal tool for creating detailed 3D visualizations, allowing users to produce complex models and present them professionally to clients. In this project, Revit was instrumental in providing an accurate and complete conceptual layout for the edible oil refining unit, enabling the client to understand the spatial flow and visual appeal of the entire facility.

PDMS Capabilities for Industrial Design

PDMS is one of the most commonly used tools for the layout and spatial arrangement of large industrial facilities. It enables comprehensive management of equipment layouts, checks for spatial conflicts, and optimizes space usage, which makes it invaluable for industrial projects such as this one. Here, PDMS allowed us to enhance spatial efficiency and ensure functional flow within the refinery.

Conclusion

Using Revit and PDMS, this project successfully achieved a comprehensive 3D conceptual design of an edible oil refining unit. Created for client presentation without intricate technical details, this conceptual layout effectively showcases the spatial arrangement and general appearance of the facility. Employing this design approach allows for cost and time savings, giving the client a complete overview of the unit’s layout while facilitating any necessary changes before the construction phase.

Suggested Applications

This project serves as a valuable resource for educational purposes, industrial design research, and pre-construction presentations for clients. The 3D conceptual design allows for thorough analysis and review of equipment placement and space utilization, assisting clients in understanding the complete facility before construction begins.