Description

In this project, 100 to 700 NOURI (Borzooyeh) Petrochemical units are simulated using industrial PFDs by Aspen Plus version 10 software.

The process units of Nouri Petrochemical Company are:

Unit 100- Hydrogenation of Benzene, Pyrolysis

The pyrolysis benzene received from Jam Petrochemical is entered into this unit. And after passing through the catalytic beds and separating nitrogenous, sulfurous and olefinic compounds, it is sent to the reformite and aromatics separation unit.

Unit 200 – Preparation of Gas Condensate (Separation of Light and Heavy Compounds From Gas Condensate)

The gas condensate received from South Pars Gas Complex Company entered this unit after entering the complex. And in this unit, light and heavy compounds are separated and then the product of this unit is sent to the hydrotreating unit.

Unit 250- Hydrotreating (Refining The Intermediate Product Output From Unit 200)

The output product from unit 200 in this unit after passing through the catalytic beds, its nitrogenous and sulfurous compounds are separated and then sent to the catalytic reforming unit.

Unit 300-Catalytic Reforming (Transformation of Paraffinic and Naphthenic Compounds Into Aromatic Compounds)

The feed of this unit includes paraffin compounds. A large amount of these compounds are converted into aromatic compounds after passing through catalytic reactors. And the hydrocarbons enriched with aromatics are sent as a product of this unit along with the output from unit 100 to the reformite and aromatics separation unit.

Unit 350 – Catalyst Regeneration

The catalysts in the four reactors of unit 300 are regenerated in this unit by the continuous circulating bed method. In this mechanism, the catalyst is deactivated. Reactors of Unit 300 are continuously entering Unit 350. And after revival, it is returned to the reactors of unit 300.

Unit 400- Separation of Reformite and Aromatics and Production of Ortho Xyline

Output products from units 300 and 100 are the feed of this unit. In this unit, three intermediate products, BT, mixed xylene and C9+, as well as the final product ortho xylene, are produced. BT product includes benzene, toluene and non-aromatic hydrocarbons. and sent to the extraction unit. The mixed xylenes are sent to the paraxylene separation unit and the 9-carbon hydrocarbons are sent to the transalkylation unit. Ortho xylene is also one of the main products of the complex and enters the storage tanks.

Unit 500- Extraction of Benzene and Toluene (Separation of Aromatics from Non-Aromatic Hydrocarbons by Morpholine Solvent)

The mixture of benzene, toluene and non-aromatic hydrocarbons along with morpholine solvent is entered into this unit. And under the extractive distillation process, aromatic compounds including benzene and toluene are separated and sent to unit 600 to separate each of them. Non-aromatic compounds are also sent as a by-product of raffinate to Jam’s olefin petrochemical unit.

Unit 600-Disproportionation (Separation of Benzene From Toluene and Conversion of Toluene Into Benzene and Mixture of Xylenes)

The mixture of benzene and toluene is the feed of this unit. After passing through different parts of this unit, benzene and toluene are separated. Benzene enters the storage tanks as another main product of the complex. And toluene is sent to the reactor of this unit. In this reactor, toluene is converted into benzene and a mixture of xylenes. After this conversion, the benzene product is separated and the mixture of xylenes is returned to the Reformit and aromatics separation unit.

Unit 650- Transalkylation (Transformation of 9-Carbon Hydrocarbons Into a Mixture of Xylenes)

9-carbon hydrocarbons output from unit 400 form the feed of this unit. After passing through the catalytic reactor, this feed turns into a mixture of xylenes. The mixture of xylenes is returned to the reformite and aromatics separation unit to separate its components.

Unit 700- Isolation of Paraxylene (Production of Paraxylene From a Mixture of Xylenes by Molecular Sieves)

The mixture of xylenes coming out of unit 400 forms the feed of this unit. In this unit, using molecular sieves and paradiethylbenzene solvent, paraxyline was isolated. And then the rest of the xylene mixture, including metaxylene and ethylbenzene, is sent to the isomerization unit to convert to paraxylene.

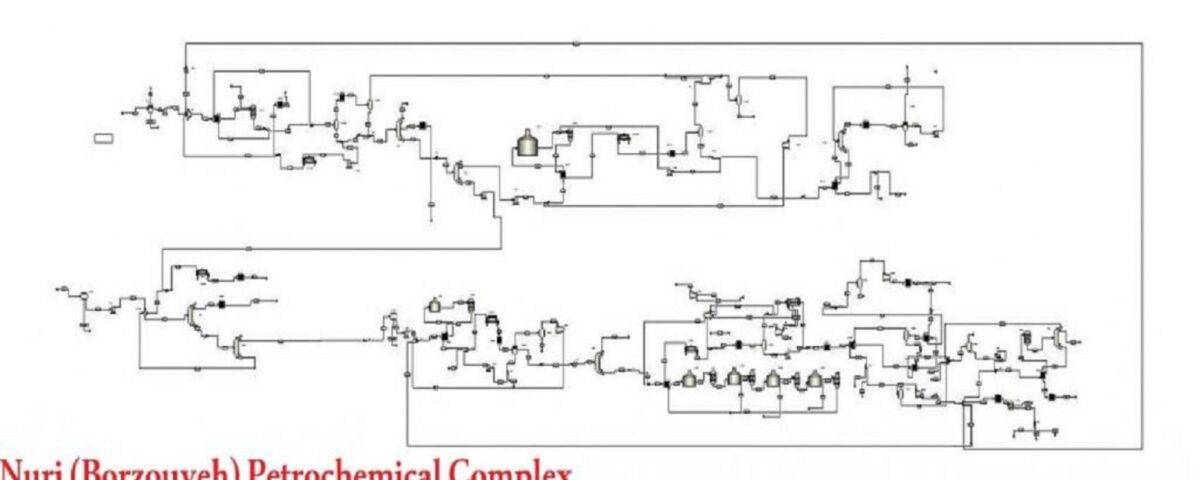

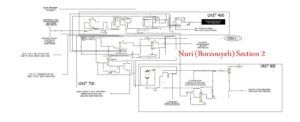

100 to 300 Unit Simulation

400 to 700 Unit Simulation

Energy and Exergy Analysis, NOURI Petrochemical

In this project, energy and exergy analysis has been done for all units and the optimization of towers is also on the agenda.