Description

Removing acidic agents such as CO2 in a mixture of gases, especially in natural gas. is very important due to corrosion or freezing in the transmission network or process equipment. Liquid phase adsorption is the most common commercial method of gas sweetening in refineries and gas sweetening processes, especially for the adsorption of carbon dioxide gas. It brings the lowest operational and process costs. Adsorption processes in liquid are divided into physical and chemical categories.

In the physical adsorption method, the impurities of the gas stream are dissolved in the liquid phase through the creation of intermolecular forces. But in the process of chemical adsorption in the liquid phase, alkanolamine solutions are generally used as adsorbents. These materials have been used in the gas sweetening industry due to their cheapness and absorption reaction properties. Amine solutions used in the industry as absorbents are mono 4 and 3, methyl diethyl amine, triethyl amine, diethyl amine and ethyl amine.

Factors Affecting CO2 Absorption Tower Performance

-

Type of Absorbent Material: The selection of an appropriate absorbent material is based on the type of gas, temperature, pressure, and CO2 concentration.

-

Temperature and Pressure: Temperature and pressure significantly influence the amount of CO2 absorbed by the absorbent material.

-

Gas Flow Rate: The flow rate of the gas affects the contact time of the gas with the absorbent material, consequently impacting the absorption efficiency.

-

Particle Size of Absorbent Material: The size of the absorbent particles affects the contact surface area between the gas and the absorbent, thereby influencing the absorption rate.

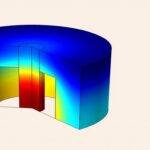

In recent years, due to the increasing use of fossil fuels and various processes in the oil, gas, and petrochemical industries, the emission of carbon dioxide has become a significant environmental issue. Given the importance of this topic, this project focuses on simulating the CO2 absorption process using COMSOL software.

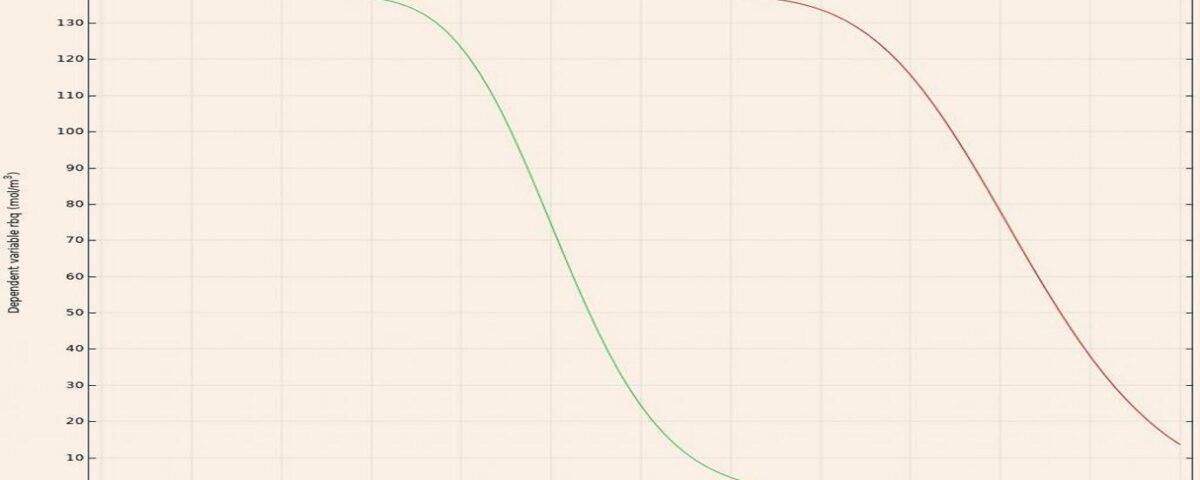

The dynamic absorption process over various times within the absorption tower is illustrated in the video below. Click to download.

Concentration Movie

Conclusion

The carbon dioxide (CO2) absorption tower is an industrial equipment used to remove or reduce the amount of carbon dioxide from various gas streams. These towers are widely used in various industries, including power plants, refineries, ammonia production facilities, and the chemical industry.