Introduction

Acetic anhydride, often represented by the chemical formula [CH3CO]2O and symbolized as Ac₂O, is a critical chemical compound extensively used as a raw material in various industrial applications. As a vital component in the production of cellulose acetate, it plays a fundamental role in creating materials for textiles, plastics, and coatings. Additionally, acetic anhydride is widely employed in acetylation reactions, where an acetyl group is introduced into organic molecules to produce essential compounds like peracetic acid, diacetyl peroxide, acetates, and esters. It is also used to absorb water from chemical reactions, making it valuable in organic synthesis and chemical analysis as a solvent.

Applications of Acetic Anhydride

- Cellulose Acetate Production: Acetic anhydride is essential in producing cellulose acetate, which is widely used in textile fibers, film production, and coatings.

- Pharmaceutical Industry: It plays a significant role in synthesizing various drugs, especially in acetylation processes that produce compounds like aspirin.

- Chemical and Agricultural Industries: Acetic anhydride is used to manufacture a range of chemicals, including pesticides and food additives.

Need for Domestic Production of Acetic Anhydride

Currently, domestic production of acetic anhydride is limited, leading to reliance on imports for this essential compound. Given its widespread applications, increasing local production could significantly enhance the efficiency of downstream industries and reduce dependency on imported materials. As such, producing acetic anhydride offers an attractive investment opportunity within the petrochemical industry.

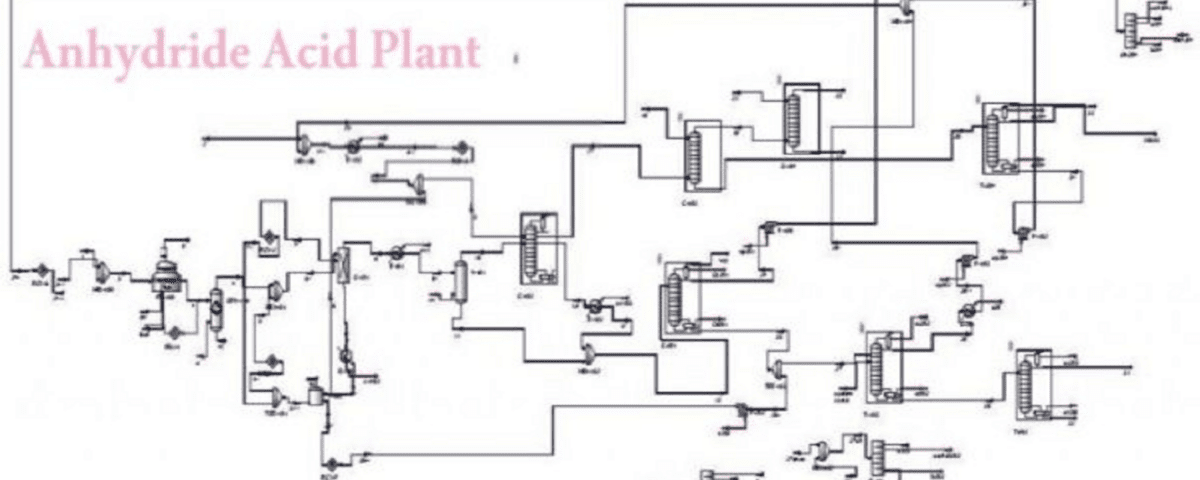

Simulation of Acetic Anhydride Production Process Using Acetone and Acetic Acid

This project focuses on simulating the production of acetic anhydride from acetone and acetic acid using Aspen HYSYS version 10. The simulation is based on process diagrams from the SRI Library, a well-regarded source for industrial data. Process simulation provides an effective method for evaluating and optimizing production units by enabling precise analysis of operating conditions, performance, and energy consumption.

Project Details

- Software: Aspen HYSYS (Version 10)

- Basis: SRI Library process diagrams

- Outputs: Simulation files detailing the production process

- Reports: This project includes only the simulation files and process flow diagrams (PFDs) without additional reports.

Benefits of Acetic Anhydride Production Simulation

- Optimization of Operating Conditions: Simulation helps identify optimal production conditions, resulting in cost reduction and improved efficiency.

- Energy Consumption Reduction: By analyzing energy consumption and identifying points of inefficiency, the production process can be further optimized.

- Performance and Efficiency Prediction: This simulation provides valuable insights into the production unit’s performance under various operational conditions.

- Reduced Import Dependency: Increasing domestic production of acetic anhydride reduces reliance on imports and ensures a steady supply for downstream industries.

Conclusion

The production of acetic anhydride from acetone and acetic acid using Aspen HYSYS simulation software can make a significant contribution to the country’s petrochemical industry. This process is economically viable and strategically important, as it can reduce dependency on imports and boost the efficiency of downstream sectors. Therefore, pursuing similar projects and developing domestic production of acetic anhydride is highly recommended as an essential step towards self-sufficiency in the petrochemical sector.

Available Files

- Simulation File: Project simulation files in Aspen HYSYS

- SRI Process Diagrams: Standard process flow diagrams for acetic anhydride production