Description

Monoethylene Glycol (MEG) is an organic compound belonging to the diol family, primarily used in the production of polyethylene terephthalate (PET) and as an engine coolant. Ethylene glycol (EG) is typically produced from ethylene and oxygen. Given Iran’s substantial ethane resources and numerous ethylene production units, the country has a comparative advantage in MEG production.

Monoethylene Glycol (MEG) Unit

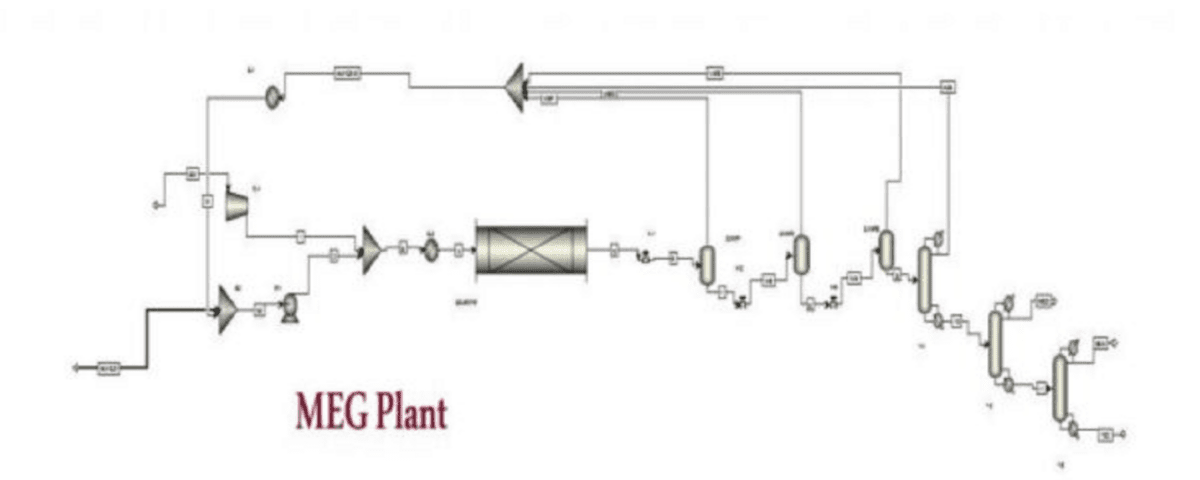

In MEG production, aqueous ethylene oxide from the Light End column base is heated through three heat exchangers before entering the ethylene glycol reactor, where MEG, DEG, and TEG are produced. This glycol stream then moves through three consecutive contactors, known as Glycol Concentrators, where water is removed, and glycol is concentrated. The removed water is eventually converted to steam.

The partially dehydrated glycol stream is then sent to the Glycol Dehydrator column for final dehydration. Water exits from the top, while the ethylene glycol stream, now termed Crude Glycol, moves to the glycol separation unit. Initially, glycol enters the MEG column, where pure monoethylene glycol is separated via a side draw, cooled, and stored.

After cooling and condensation, the overhead stream is recycled back to the Dehydrator column. The bottom stream continues to the MEG Recycle column, where the top product, after cooling and condensation, merges with the previous overhead stream. The bottom stream of the MEG Recycle column, rich in DEG and TEG, flows to the DEG column. Here, pure DEG is separated at the top, cooled, and stored, while the remaining stream enters the TEG column for further separation from residual components.

Conceptual Design of the Monoethylene Glycol Production Unit in Aspen Plus

This project, designed for a Conceptual Design course at the University of Isfahan, utilizes process information from handbooks and research articles to develop a conceptual design for MEG production. The focus was on selecting processes and equipment for production and separation units. The MEG unit was then simulated using Aspen Plus software. Additionally, an economic analysis was conducted using Aspen Economic Analyzer to determine the optimal production capacity.

Available Files: Conceptual Design Report – Process Simulation File