Introduction

Combined Heat and Power (CHP) and Combined Cooling, Heat, and Power (CCHP) plants have gained significant attention in recent decades as some of the most advanced and efficient methods of energy generation. By simultaneously producing electricity and heat, these systems achieve much higher efficiency compared to traditional energy generation systems. Through the integration of gas and steam turbines, combined cycles maximize the conversion of thermal energy into electricity and useful heat. As a result, they not only reduce fuel consumption but also minimize environmental impacts.

The effective use of surplus heat generated during electricity production supports heating and hot water needs in buildings and industries, thereby relieving additional loads on electrical grids.

With the increasing focus on reducing energy consumption and optimizing efficiency, technical and economic analysis of combined cycle units can offer deeper insights into their functionality and highlight their potential capabilities.

Description

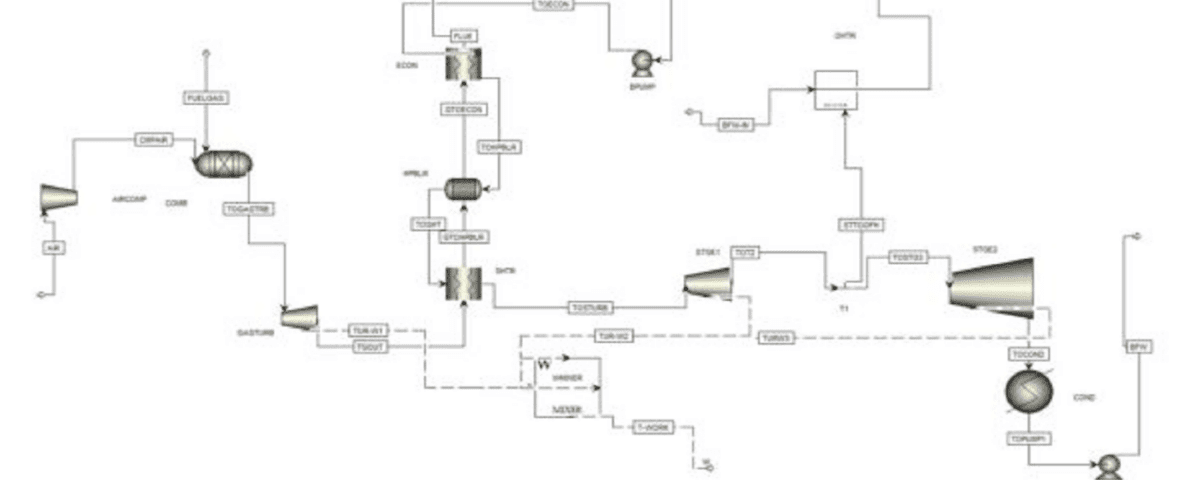

Hydrogen is considered one of the cleanest fuels and has versatile applications in various processes. Among the different methods of hydrogen production, synthesis gas (syngas) conversion is notable. In this study, natural gas is initially converted into syngas within an autothermal reactor. Subsequently, in water-gas shift reactors, carbon monoxide is converted to carbon dioxide. The resulting gas undergoes CO₂ capture, and the hydrogen-enriched gas, mixed with nitrogen, is burned in a gas turbine to generate electricity. The hot gas exiting the gas turbine is directed into a heat recovery steam cycle, where steam generated at two pressure levels produces electricity through steam turbines. These processes are simulated using Aspen Plus software, based on the data presented in the referenced paper.

Conclusion

The Aspen Plus simulation of a combined cycle (CHP/CCHP) unit demonstrates that these systems offer higher energy efficiency, reduced pollutant emissions, and significant economic savings, positioning them as efficient and sustainable energy solutions. Their capability to supply electricity and heat simultaneously enhances both hydraulic and economic flexibility, though certain technical challenges in design and operation remain. Process optimization and integration with renewable resources could further improve performance. In summary, CHP/CCHP combined cycle units present a viable solution for sustainable energy production and reduced environmental impacts.