Introduction

The transportation of sour gas from offshore platforms to onshore refineries is consistently challenged by various issues, such as hydrate formation and corrosion, which can adversely affect the efficiency and safety of gas transmission lines. To mitigate these challenges, glycol injection is commonly employed as a solution. Several types of glycols are used for industrial applications, including monoethylene glycol (MEG), diethylene glycol (DEG), triethylene glycol (TEG), and tetraethylene glycol (TetraEG). Glycols are advantageous for preventing hydrate formation in high-pressure and low-temperature conditions during gas transmission due to their higher boiling points and lower vapor pressures compared to water.

MEG Recovery Unit

1. Importance and Function of MEG Injection in Gas Lines

The injection of monoethylene glycol (MEG) plays a crucial role in preventing hydrate formation and combating corrosion in gas transmission lines. MEG is injected at offshore platforms into the gas lines that lead to onshore facilities. By injecting MEG, the stability of the transmitted gas is maintained, preventing potential blockages and failures in the lines, which significantly reduces maintenance and repair costs.

2. MEG Recovery Process

Once the gas reaches the onshore facilities, MEG is separated from the gas flow and sent to the MEG recovery unit. This unit is designed to:

- Remove hydrogen sulfide (H₂S) and other impurities from the glycol solution

- Increase the glycol concentration from approximately 30% to 70% by weight

This process enables the reuse of MEG in the gas transmission system and helps reduce operational costs.

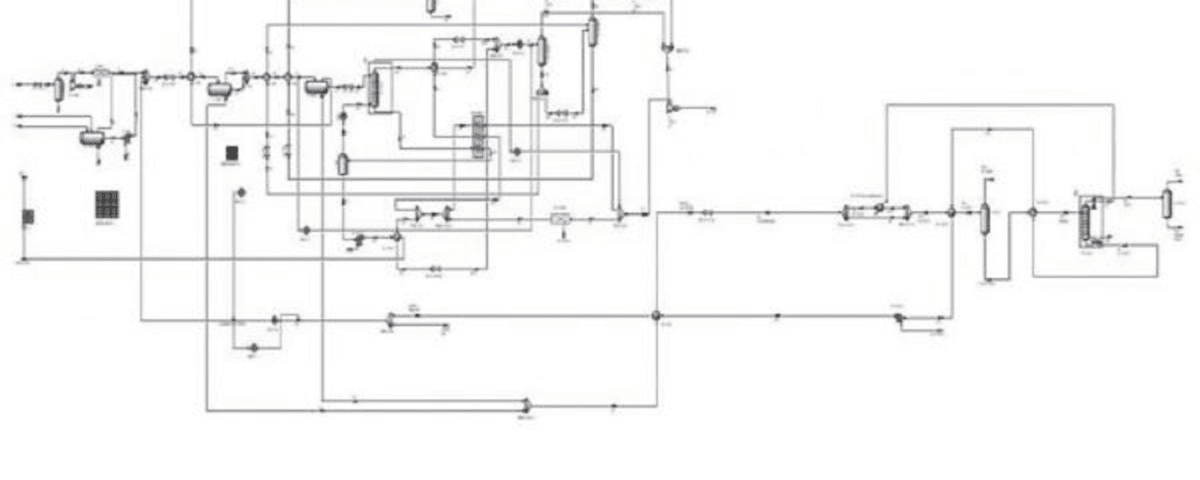

MEG Recovery Unit Simulation in Aspen Plus

1. Overview of the Simulation in Aspen Plus (Version 10)

The simulation of the MEG recovery unit was performed in Aspen Plus Version 10, a software renowned for its high accuracy in simulating gas processes. This simulation involved modeling the cooling heat exchanger at the unit’s end and optimizing it to enhance the efficiency of MEG separation and concentration. This step is particularly important for removing toxic gases and impurities from the glycol solution, thereby maintaining the high quality of the MEG flow.

2. Optimization and Design of the Cooling Heat Exchanger

In this part of the simulation, the cooling heat exchanger was designed to increase the thermal efficiency of the MEG recovery unit. The simulation considered various factors such as temperature, pressure, and flow rate to determine the optimal configuration for MEG recovery while minimizing energy consumption. Using advanced thermodynamic models in Aspen Plus allows for accurate predictions of these variables’ impacts, resulting in optimized design and better system performance.

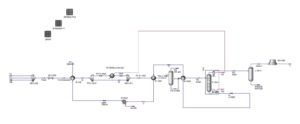

Complementary Simulation in Aspen HYSYS: Process Validation and Verification

The MEG recovery unit was also simulated in Aspen HYSYS to verify the results obtained from the Aspen Plus simulation and ensure the accuracy of its thermodynamic calculations. The HYSYS simulation provided additional insights for optimization analyses and confirmed the correct behavior of the system under various conditions.

Benefits and Impacts of MEG Recovery in Sour Gas Processing

Implementing MEG recovery in the gas sweetening process offers multiple advantages:

- Cost Savings: Reusing MEG reduces the need for a continuous supply of fresh glycol, significantly lowering operational costs.

- Environmental Protection: By minimizing waste and chemical consumption, MEG recovery contributes to environmental sustainability.

- Operational Efficiency: This process ensures a continuous supply of MEG and prevents disruptions due to glycol depletion.

- Increased Safety: Removing impurities and hazardous gases such as H₂S helps reduce risks associated with exposure to toxic materials, enhancing operational safety.

Conclusion

Effective MEG recovery plays a vital role in the success of gas sweetening operations, providing a reliable solution for managing the challenging conditions of offshore and onshore gas transportation. The simulations performed in Aspen Plus and HYSYS not only offer accurate modeling of the recovery unit but also optimize design and performance, leading to reduced costs, increased safety, and improved environmental sustainability. For companies seeking to maintain the integrity and efficiency of their gas transmission systems, integrating these simulations into project processes can have a significantly positive impact.

MEG Simulation and Recovery for Gas Refining with Aspen Plus and HYSYS

The simulation was conducted using real refinery data to ensure that the designed model closely resembles actual operating conditions. Due to confidentiality agreements, these simulation files are not publicly shared.Available files for this project:

- Aspen Plus simulation files

- Aspen HYSYS simulation files

- Complete cooling tower design for unit optimization