Introduction

This process is used to recover sulfur compounds from sour gas streams in oil and gas refineries to prevent the release of polluting gases and to produce sulfur. One of the most significant uses of sulfur in the world is in the production of sulfuric acid.

Typically, oil refineries must reduce the amount of sulfur compounds in their products to meet quality and environmental standards. Hydro-treating processes are designed and constructed in refineries for this purpose. In these processes, sulfur compounds present in crude oil fractions are converted to hydrogen sulfide (H2S) gas. To recover the sulfur present in this gas stream, the sulfur recovery unit (SRU) or Claus process is used. In gas refineries, amine towers are typically used to remove sulfur compounds from produced gases and sweeten the gas. At the end of this process, sulfur compounds are also produced in the form of hydrogen sulfide, which needs to be recovered as sulfur using the Claus process.

Claus Process

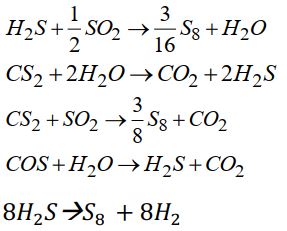

The Claus process is based on the conversion of hydrogen sulfide to elemental sulfur through a series of chemical reactions. In this process, sulfur is produced after two reaction stages. Initially, in the first stage, in the furnace and in the presence of iron catalysts, hydrogen sulfide gas is converted to sulfur dioxide (SO2). Then, in the second stage and in separate reactors, the remaining hydrogen sulfide gas reacts with sulfur dioxide in the presence of activated alumina catalysts in several stages to form elemental sulfur. The conversion rate in the sulfur recovery (Claus) process is 90 to 95%. Therefore, a certain amount of gas containing sulfur compounds will exist at the end of this process, which is known as tail gas. Due to the existence of environmental standards, refineries are required to treat this gas before releasing it into the atmosphere. The reactions of this process are as follows.

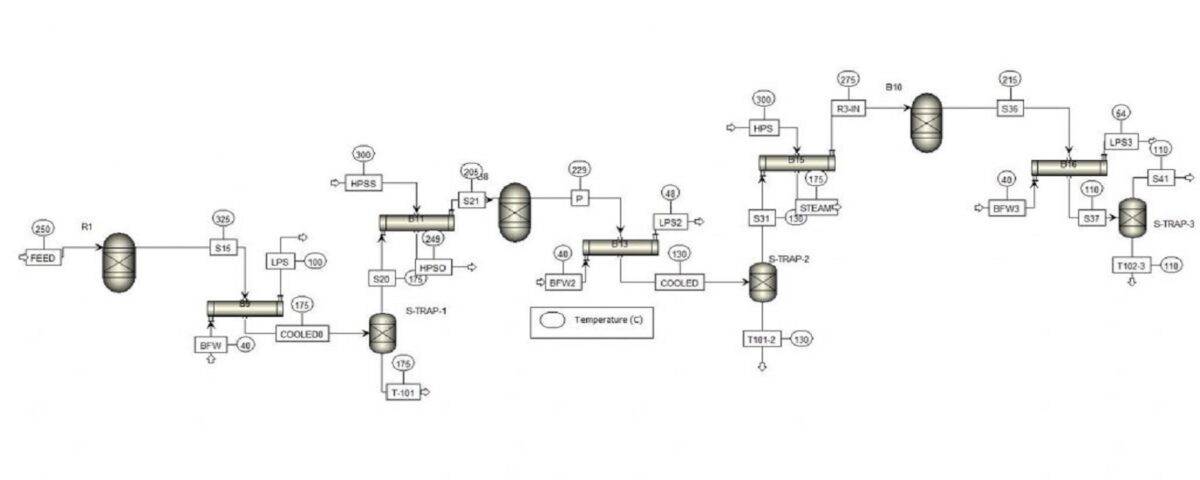

Sulfur Recovery (SRU) Process Simulation

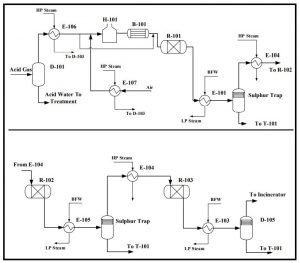

In this project, the sulfur recovery process has been simulated with Aspen Plus software using data from Sediqi et al.’s paper. The following figure shows the process flow diagram of the SRU unit.

Some of the Results