Introduction

In this project, several process design exercises have been solved and reviewed with Aspen Plus and Hysys software.

Class Exercise 1

Question 1

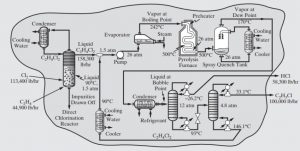

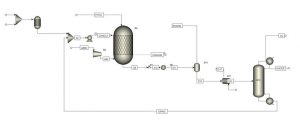

Simulation of a Vinyl Chloride Production Unit in Aspen Plus.

Question 2

To produce monoethylene glycol (MEG), diethylene glycol (DEG), triethylene glycol (TEG), and tetraethylene glycol (4EG), report the initial database including the physical and chemical properties of the materials, along with their references.

Question 3

In a process, the target is to synthesize 150,000 kg/h of MEG. Develop a step-by-step synthesis tree for MEG production. The available feedstock for this plant is water and ethylene oxide at ambient temperature and pressure. Therefore, consider the synthesis route based on this feedstock and operating conditions. The optimal conditions for the MEG production reactor are considered to be 170°C and 35 bar. The simulation of the reactions in this reactor is provided in the exercise guide. For product separation, a separator can be used instead of a distillation column. The production of 100 kg/h of 4EG is also desired as a byproduct.

Question 4

In the synthesis process of vinyl chloride production, follow the Reaction Path 5 scenario to the end. At each step, follow one of the possible paths from the synthesis tree. (Use flash calculations from Aspen Plus or Aspen Hysys software to determine the temperature or composition of the process streams.)

Class Exercise 2

Question 1

Analysis of ethanol properties

Question 2

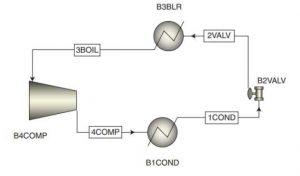

Simulation of a car air conditioner

Question 3

Methane liquefaction unit simulation. This simulation was tested with Aspen Plus and Aspen HYSYS software.

Class Exercise 3

Question 1

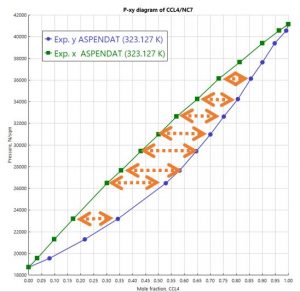

Draw a P-xy diagram for carbon tetrachloride and normal heptane

Question 2

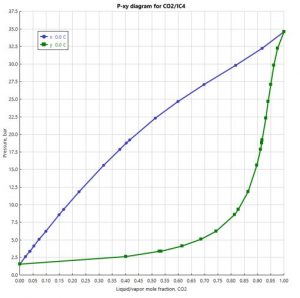

Draw the vapor-liquid equilibrium diagram of carbon dioxide and isobutane

Question 3

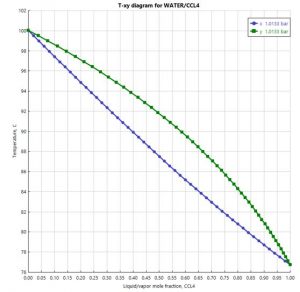

Draw a vapor-liquid equilibrium diagram for carbon tetrachloride and water

Question 4

Draw a liquid-liquid diagram for propanoic acid ethyl ester and water

Class Exercise 4

Question 1

Synthesis gas is used in various processes such as methanol production, dimethyl ether (DME) production, and gas-to-liquids (GTL) conversion. One of the methods for producing synthesis gas is using a steam methane reforming (SMR) reactor. Using simulation, simulate the production of synthesis gas on a commercial scale with suitable operating conditions and composition for the production of methanol, DME, and GTL. Consider pure methane as the hydrocarbon feed to the reactor, and use industrial reactor temperature and pressure conditions. Please cite the references used.

Question 2

Simulate the ammonia synthesis process in a series of 3 catalyst beds.

Question 3

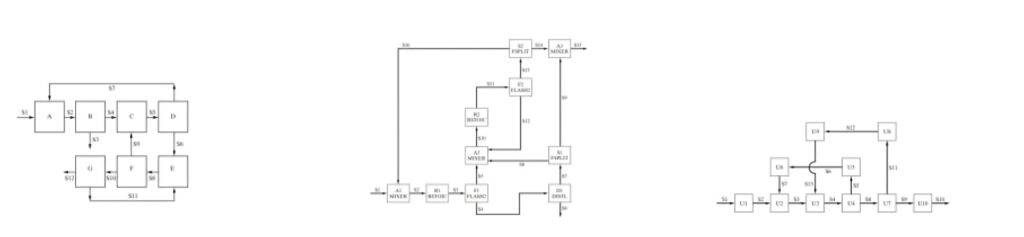

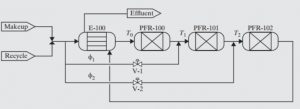

Consider the following block diagrams

Stream S1 is designated as the feedstream in all three block diagrams. Consider the tear streams in a way that minimizes the required number of tears in each block diagram. Subsequently, report the solution order for each block diagram.