Description

Microchannels are very narrow channels with dimensions in the micrometer (millionth of a meter) scale. These small channels play a very important role in various industries and have diverse applications.

Definition and Characteristics

Microchannels are usually fabricated through micromachining processes on various materials such as silicon, glass, polymers, and metals. These channels can have various geometric shapes such as straight, spiral, and branched.

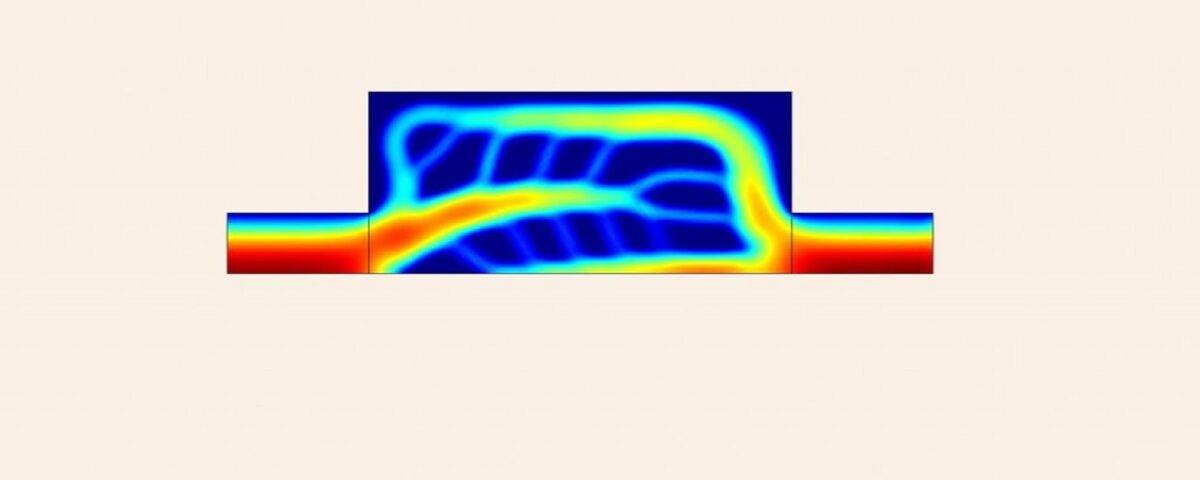

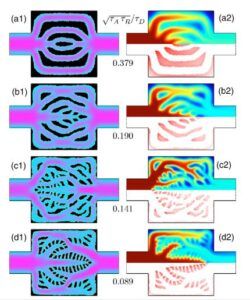

Chemical processes play a key role in the production and analysis of many substances and materials needed in industry and healthcare. In general, optimizing these processes is an important goal. And with the introduction of microfluidic reactors including slow flows, the obtained concentration distribution means better control and use of reactors.

These conditions make it possible to design reactors using the topology optimization method. The scaling is theoretically predicted and numerically verified. In addition, in this project, the method of significantly increasing the reaction rate by distributing active porous materials inside the reactor has been investigated. This is done using a high-level implementation of topology optimization.

This simulation is done with the help of Comsol software and it has an educational video.