Introduction

Propylene, also known as propene or methyl ethylene, is readily obtained from light petroleum fractions. It can be produced by steam cracking of propane and heavier fractions. This project aims to simulate a unit designed to remove impurities from propylene feedstock.

Ethylene and propylene are among the most important petrochemical feedstocks, offering higher added value than raw materials such as natural gas and naphtha. However, propylene requires special attention due to its unique supply and demand dynamics. In recent years, the focus on ethylene production has led to a significant increase in ethylene capacity relative to propylene, especially considering that ethylene is a co-product in most conventional propylene production processes.

Propylene is a key petrochemical feedstock used in the production of various polymers and intermediates. Major propylene derivatives include polypropylene, acrylonitrile, propylene oxide, phenol, oxo alcohols, acrylic acid, isopropyl alcohol, oligomers, and various other intermediates that ultimately find applications in industries such as electronics, automotive, construction, packaging, and more.

Propylene Production

Conventional methods for producing propylene include steam cracking (where propylene is a co-product of ethylene production) and recovery from refinery FCC units. Typically, the propylene produced by these methods is limited in quantity and efficiency. Therefore, it is essential to assess the global demand for propylene and determine whether these conventional methods can meet this demand. If not, alternative technologies and processes for producing propylene, particularly those that do not co-produce ethylene, must be explored.

In addition to the desired propylene product, propylene units often contain impurities such as mercaptans and acidic gases like carbon dioxide. Among the most harmful impurities for polypropylene production is carbon monoxide, which must be completely removed.

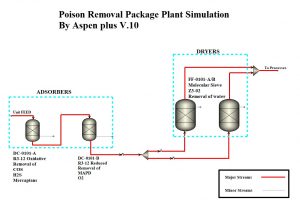

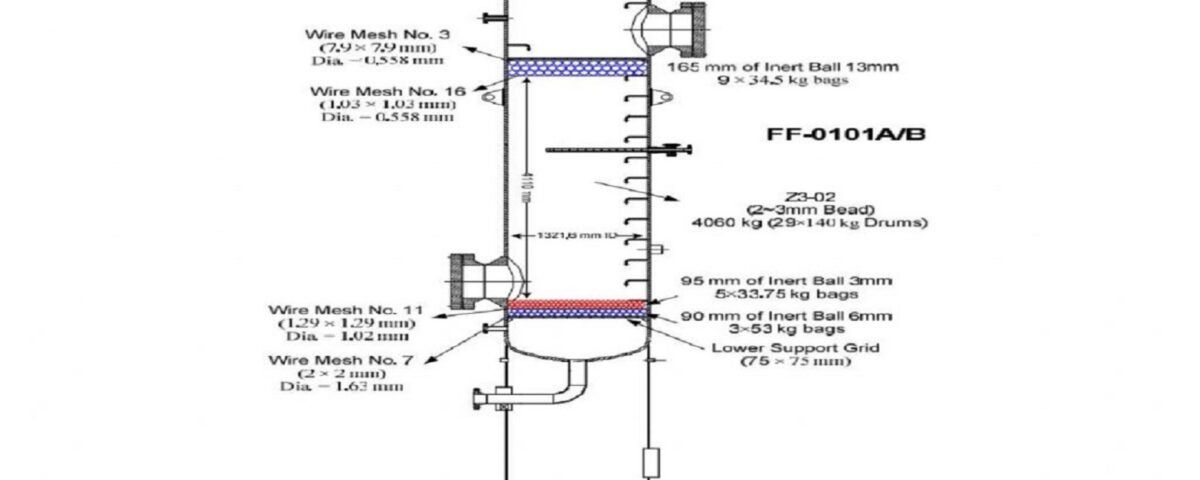

Simulation of Toxic Substance Removal Unit from Olefinic Propylene Feed

In this plan, the simulation of the unit for removing toxic substances from olefinic propylene feed has been done with Aspen Plus software. The figure below shows the overview of the simulation.