Biodiesel: A Chemical Engineering Perspective

Biodiesel, or bio-diesel, is a renewable fuel produced from vegetable oils or animal fats through a process called transesterification. It serves as a potential substitute for petroleum diesel. While biodiesel was first introduced in the 1970s, its widespread adoption was limited until recent years. With dwindling fossil fuel reserves and increasing environmental concerns, biodiesel has gained significant attention.

Biodiesel and petroleum diesel exhibit similar molecular sizes but differ significantly in their chemical composition. Biodiesel molecules primarily consist of fatty acid methyl esters, containing unsaturated aliphatic compounds. In contrast, petroleum diesel (low-sulfur) is composed of approximately 95% saturated hydrocarbons, with the remaining 5% being aromatic compounds.

If ethanol is used instead of methanol in biodiesel production, the resulting molecules are fatty acid ethyl esters. These chemical structural differences give rise to distinct physical properties, which will be discussed in terms of advantages and disadvantages.

How to Produce Biodiesel

Biodiesel can be produced from vegetable oils, tallow, waste cooking oils, or animal fats. This process is achieved through transesterification, which yields biodiesel and glycerol as products. Approximately 100 parts (by weight) of oil or fat react with 10 parts of a short-chain alcohol (typically methanol) in the presence of a catalyst (usually sodium hydroxide or potassium hydroxide), ultimately producing 100 parts of biodiesel and 10 parts of glycerol.

Methods of Production Biodiesel

1. Microemulsion or Emulsification Method

Microemulsion fuels are a blend of vegetable oils, alcohol, and specific chemicals that can serve as a substitute for fossil fuels in diesel engines. These fuels offer several advantages:

- Reduced fossil fuel consumption: By replacing a portion of diesel fuel with microemulsions, fossil fuel consumption can be significantly decreased.

- Utilization of renewable resources: Vegetable oils and alcohol, which are renewable resources, are used in the production of microemulsions.

- Reduced emissions: Microemulsions can help reduce the emission of harmful pollutants from diesel engines.

Microemulsions have a very fine structure, which gives them desirable properties such as transparency and stability. However, there are limitations on the amount of water and free fatty acids that can be present in microemulsions for use as fuels.

2. Thermal Cracking (Pyrolysis) Method

Pyrolysis is a process where organic materials are decomposed at high temperatures in the absence of oxygen, breaking them down into smaller molecules. This process is particularly useful for vegetable oils and animal fats.

Process: In pyrolysis, the oil is first saponified with lime and then broken down at high temperatures. The products of this process include crude oil, diesel fuel, gasoline, and kerosene.

Advantages: Production of biofuels from renewable resources, reducing dependence on fossil fuels.

Mechanism: The pyrolysis mechanism of vegetable oils involves the breaking of chemical bonds in triglycerides and the formation of smaller molecules.

Technical terms and explanations:

- Microemulsion: A stable mixture of two immiscible liquids (e.g., oil and water) with the addition of a surfactant.

- Saponification: A process that converts fats and oils into soap by reacting them with an alkali (e.g., sodium hydroxide).

- Triglycerides: Esters composed of three fatty acids and one glycerol molecule, which are the main constituents of fats and oils.

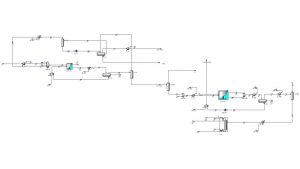

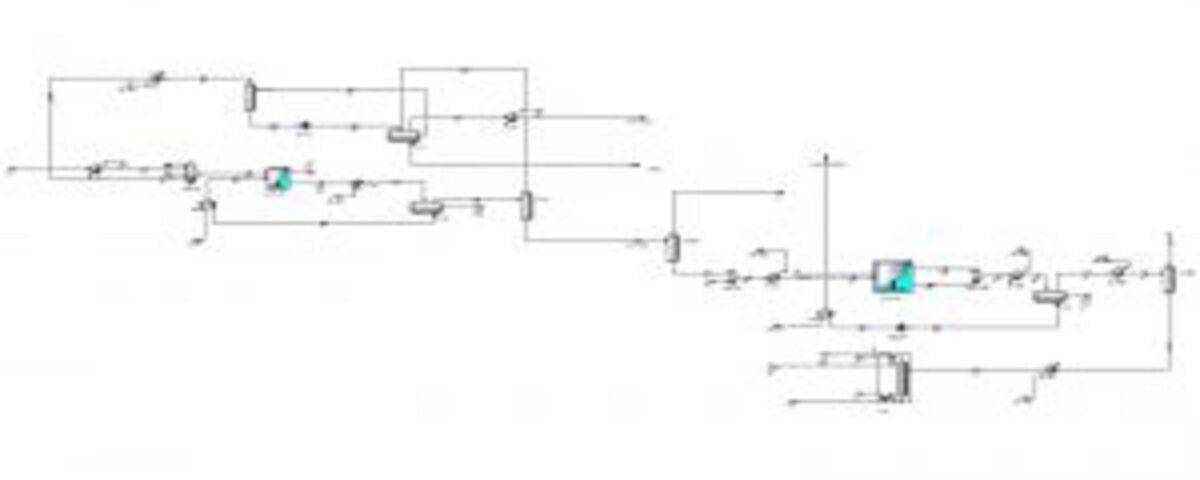

Simulation of Biodiesel Production Process

In this project, the simulation of the biodiesel production process has been carried out with Aspen Hysys software.