Description

A butane fractionation tower is a crucial piece of equipment in the oil and gas refining industry, designed to separate butane from a mixture of lighter hydrocarbons. These towers are commonly found in natural gas processing units and refineries to produce pure, high-quality butane for various applications such as fuel, petrochemical feedstock, and chemical production.

How a Butane Fractionation Tower Works

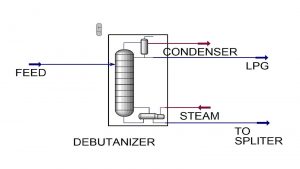

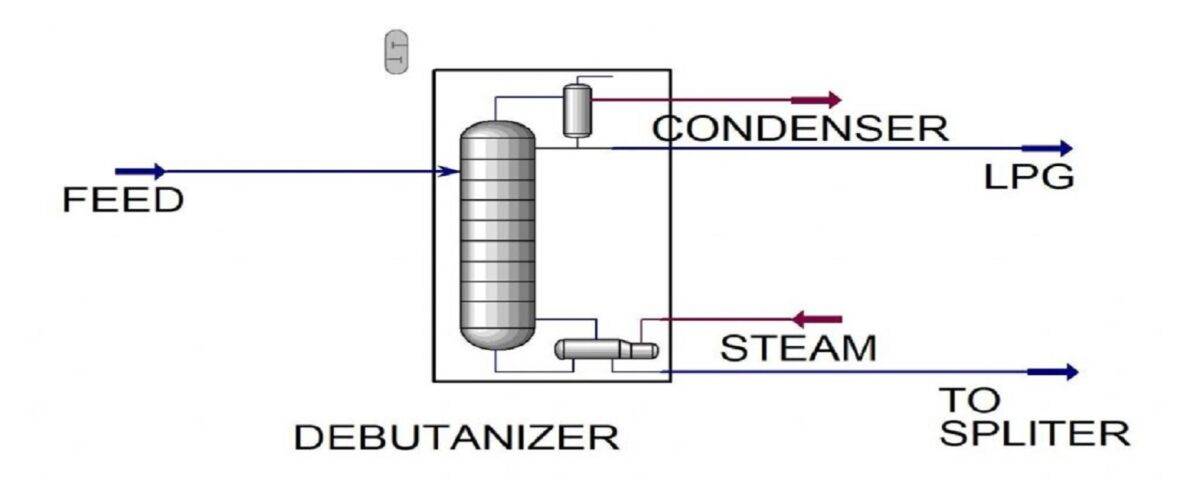

A butane fractionation tower is a vertical column containing perforated trays or plates. The feed mixture enters the tower from the top and gradually moves down through the trays. Simultaneously, steam or vapor of a lighter hydrocarbon is introduced from the bottom and travels upward. As the vapor and liquid come into contact on the trays, vaporization and condensation occur. Lighter molecules (such as propane) have a greater tendency to vaporize and move up the column, while heavier molecules (like butane) condense and flow down.

Today, chemistry and oil and gas extraction and refining is one of the most important points of economic and production reliance of countries. One of the most common processes in refineries is the separation of chemicals. This is done using separator towers. The debutanizer tower is one of the towers used in the gas refinery to separate butane from sour gas in the debutanization unit. If the proper and good control system governs this system, we can produce high quality products with minimal energy and minimal cost. In this project, we will simulate the debutanization tower.

Debutanization Tower Simulation

In this project, the debutanization tower has been simulated using information from reference books in Aspen Hysys software.