Description

The oil and gas refining industry is considered as one of the major consumers of energy and a lot of money is spent on energy supply. During refining processes, a large amount of unused gas and combustible materials enter the atmosphere directly through flares. Burning these gases in flares, in addition to causing environmental problems, is also a waste of economic resources. Natural gas has been flared along with APG (associated gas or soluble in crude oil) that there has been no serious will to recover. The fact is that flare gas operations provide safety for refineries, well facilities and other facilities related to oil and gas.

Designing an Optimal System for Recovery of Flare Gases

Until today, various methods and solutions have been presented to reduce or recover the gases sent to the flare. which is mainly done on the modification of gas producing units or in the flaring system. If using the recovery system of the gases sent to the flare, it is possible to use the flaring gases of the refinery. And through this, it produced electrical energy and other chemicals. By modifying these methods and implementing them in refinery units, not only energy recovery is done, but it is also considered from an environmental point of view and the reduction of greenhouse gas emissions.

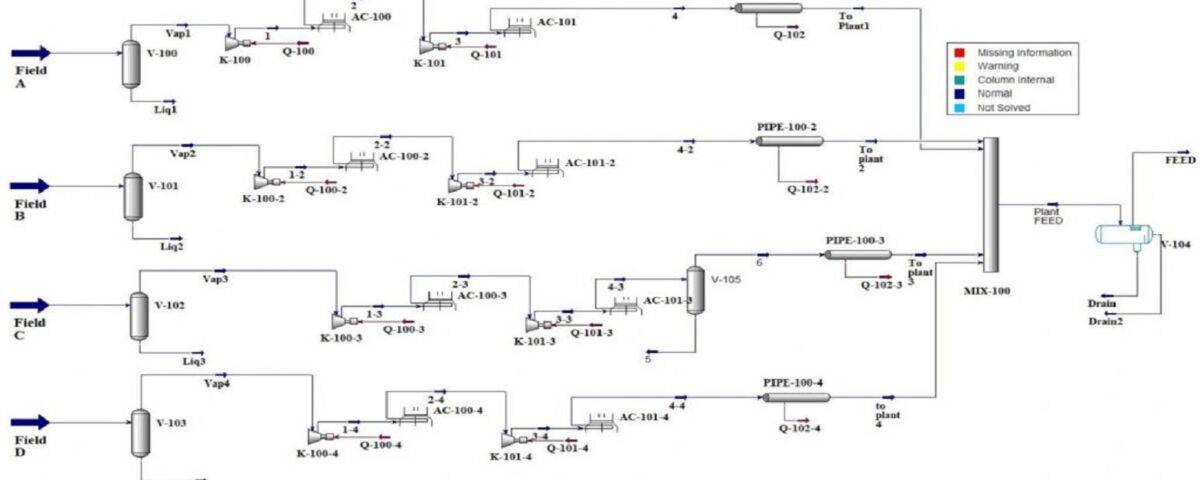

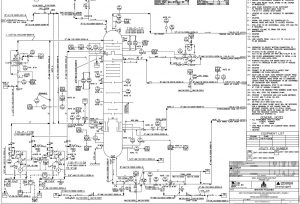

The simulation was done in Aspen Hysys software. Industrial data of VALIASR KANGAN Refinery has been used for this project. Figure below shows the industrial map of the refinery.

The figure below shows the simulation of a part of the VALIASR KANGAN Refinery.

Part of the simulation information is taken from the article below.

Development of an Optimum System to Stop Natural Gas Flaring