Introduction:

Energy conservation and pollution reduction in industries are critical issues. Gas condensates, a significant component of extracted natural gas, are often wasted due to temperature fluctuations. These condensates, which remain liquid under normal conditions, can be converted into various valuable products. Condensate stabilization, a crucial step in natural gas processing, separates lighter hydrocarbons from heavier ones. This process is typically performed using either multi-stage flash vaporization or distillation methods.

Process Description:

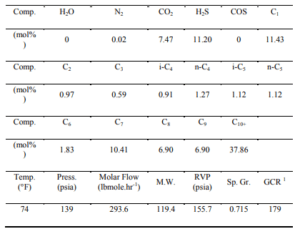

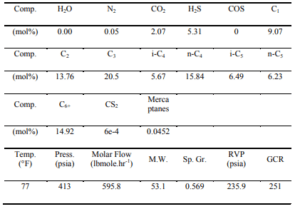

The feed for stabilization units in KHANGIRAN and NGL 3100 plants is a mixture from filter separators, slug catchers, and regeneration gas separators. The Peng-Robinson equation of state was used for thermodynamic calculations of gas and liquid phases. Due to the lack of data on boiling point curves (including ASTM and TBP distillation curves), the evaluation of +C10 and +C6 oil cut specifications was performed using their respective specific gravities (Sp.Grs.) and molecular weights (MWs). The final temperature and pressure of stabilized condensates are controlled by storage conditions, which are 35.3°C (95.5°F) and 2 bar in NGL3100, and 37.8°C (100°F) and 0.96 bar in the case of KHANGIRAN.

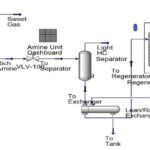

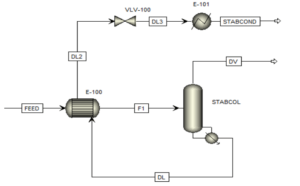

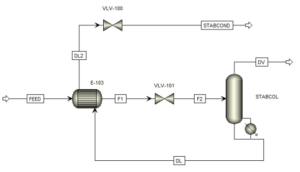

A distillation column with a boiler and no condenser (reflux column) was used (according to the figure below). The pressure of the upper tray and reboiler is considered to be 130 and 135 psia, respectively, and 140 and 145 psia, respectively, in the NGL3100 mode. The boiling ratio was set at 10 psia with the aim of having a low RVP of the product.

Results

This report examines two methods for stabilizing condensates related to NGL3100: multi-stage evaporation and distillation. Based on various criteria, including condensate recovery, total heat consumption, and H₂S content, distillation was chosen as the more suitable method. It offers higher condensate recovery, lower total heat consumption, and H₂S levels within standard limits. A simulation of gas condensate stabilization using Aspen Plus is also available on the website.

Gas Condensate Stabilization Simulation With Aspen Hysys

This project optimized the gas condensate stabilization process using HYSYS version 14.