Description

In contrast to centralized power generation systems (traditional thermal power plants), CHP power plant is considered a decentralized and local production method (District). This means that an independent power plant can be predicted for each region and neighborhood.

Thus, due to the proximity of the place of electricity production to the place of consumption, the losses caused by the transmission of electricity will be very small. While the amount of loss in the transmission routes of national networks is around 20%. (Of course, in some Iranian cities such as Ahvaz, electricity loss in the distribution network has been reported up to 30%).

In addition, the thermal energy caused by the recovery of heat losses in the generators driving the generator. And also in the cooling systems of CHP power plants (cooling towers and evaporative condensers) can be used in two high-use and practical areas:

HVAC: in order to provide the necessary energy to produce hot water needed for heating residential, office, commercial buildings, etc.

Industry: In order to meet the need of many industrial processes for thermal energy, in various industries such as petrochemicals, paper factories, etc.

Cogeneration systems use only one process to produce electricity, heat, or cooling. Therefore, the required heating/cooling and electricity capacities must be well estimated.

Based on that, system equipment should be selected appropriately. This choice should be accompanied by great care. As it is possible in a specific area and range, only a part of the required thermal power or electrical power can be provided through the CHP power plant. In a situation where it is possible that in another area, more heat and electricity have been produced than needed. In any case, a simultaneous production system will have four basic elements and components:

Propulsion Generator:

A mechanism that generates mechanical power

Electric Generator:

Mechanism that produces electricity

Heat Recovery System:

The mechanism of recovery of wasted heat

Appropriate Control System:

The management and control mechanism of all sensors and operators

In general, due to the simultaneous production and consumption of electricity in cogeneration systems, there is a need. To set up such systems in places with the following special characteristics:

Demand for energy consumption (electricity and heat) should be constant.

The demand for thermal energy consumption is high.

As much as possible, the ratio of electricity and heating demand should be balanced. In other words, the conditions for the operation of the system during the day and night and throughout the year. It should be in such a way that it is possible to realize the continuous exploitation of the system.

The figure below shows a combined CHP cycle.

The Importance of CHP in Reducing Energy Consumption

In combined heat and power (CHP) technologies, excess heat from electricity or mechanical power is recycled to reuse energy in different uses. The use of these technologies is due to the existence of a large amount of losses during the conversion of thermal energy into mechanical or electrical energy.

These losses usually enter the chimney as heat, its temperature is controlled and released into the atmosphere. By recycling some of the heat in the heat exchangers, the efficiency of the whole system increases significantly. At the same time that electricity is produced, the heat needed by commercial, industrial and public centers is also provided.

The systems of simultaneous production of heat, cold and electricity (CCHP) also provide the required thermal and cooling loads with the help of waste heat recovery in addition to the production of electric power. The increasing expansion of gas turbines and gas-burning internal combustion engines has made the use of simultaneous production systems with the primary drive of gas turbines and combustion engines very common.

In these systems, by using an absorption chiller and a heat recovery steam generator (HRSG), the excess heat released from the turbine (or combustion engine) can heat and cool the desired location without separate consumption of fuel, in addition to electricity consumption. provide This action reduces fuel consumption and also reduces the emission of pollutants.

Design of Heat Exchanger of Combined Cycle Unit (CHP)

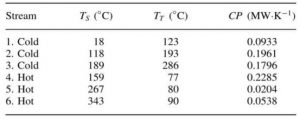

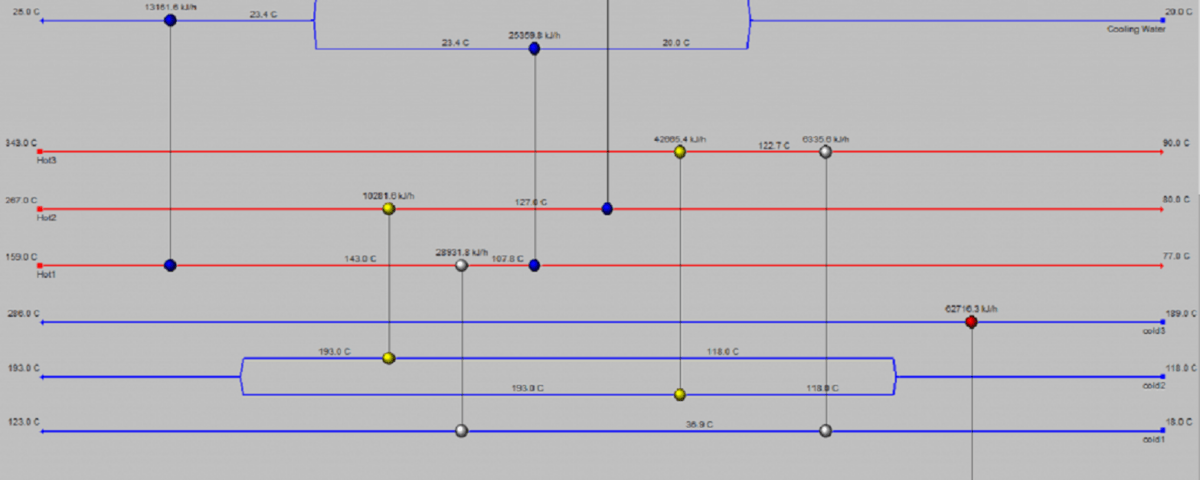

In this project, the CHP combined cycle heat exchanger network is designed in Aspen Energy Analyzer (pinch) software. The figure below shows a part of the temperature information of the currents in this design.