Description

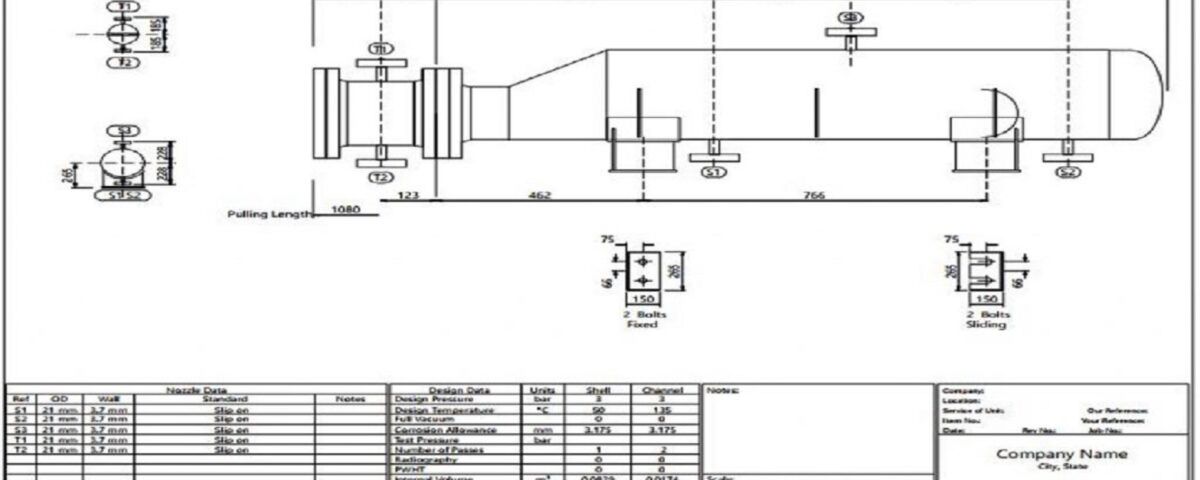

The exchanger used in the tower is Kettle reboiler type, which was chosen suitable for the process. Therefore, the detailed design of the process and operational conditions, as well as the detailed geometry and design of this equipment have been investigated. EDR software, which briefly designs heat exchangers, is used in this section. In this software, first, with the help of the design department, steps from the converter to the simulation system are given. And then, after estimating the initial geometry by the software, we improve the design conditions to reach the best possible conditions in terms of geometry and process.

As we know, the geometry is a function of the operating conditions and the evaporation or condensation capacity of the equipment has a direct relationship. This means that the geometrical design and appearance conditions of the converters should be implemented based on the required heat (Heat Load).

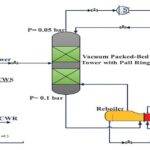

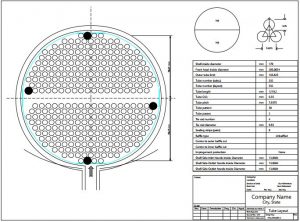

Design of Vacuum Tower Reboiler Heat Exchanger

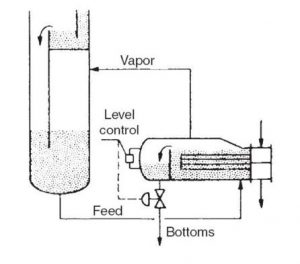

In this project, the design of the heat exchanger related to the vacuum tower reboiler (kettle reboiler) has been done in Aspen EDR software. Kettle reboiler consists of a large shell for separating liquid and vapor phases and a set of U-shaped tubes.

The liquid flow enters the reboiler shell from the end of the tower through one or more nozzles based on the force of gravity. Liquid starts to boil as a result of passing through the bunch of pipes. The steam flow in the space above the boiler is separated from the liquid flow. And it enters the tower from under the last tray of the distillation tower.

The liquid level on the bundle of tubes is controlled by a vertical baffle. And the flow of the baffle head is the product of the condensed liquid exiting from the bottom of the distillation tower. The figure below shows a part of the converter design.

This project has a report.