Description

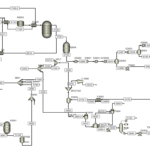

Condensate Stabilization Unit Simulation:

Gas condensate, separated from natural gas, contains volatile components such as methane, ethane, and others. Under suitable environmental conditions, these components can vaporize from the liquid phase, leading to a two-phase system and joining the gas phase. This has adverse effects on product quality, storage, and transportation. Therefore, to achieve optimal conditions for storage, transportation, and sale, it must be stabilized as a single-phase liquid. This process is known as condensate stabilization. It is performed for three main reasons:

- Removal of volatile hydrocarbons: This involves recovering methane, ethane, propane, and a significant portion of butane (or LPG) from the liquid hydrocarbon stream.

- Reducing vapor pressure: The goal is to lower the Reid Vapor Pressure (RVP) to a specified value, preventing the fluid from becoming two-phase

- Removing water, mercaptans, and acidic components: This ensures that the condensate’s water content is reduced to less than 500 ppmw and that it is free from sulfur compounds and acidic elements. (It’s worth noting that gas condensates naturally contain very low levels of H2S and CO2 compared to gaseous hydrocarbon streams.)”

Simulation of Gas Condensate Stabilization Unit

In this project, a gas condensate unit was simulated, drawing upon the data presented in the following article. Additionally, a preliminary economic analysis was conducted. To access the article, please click on the link below.

Simulation and optimization of a condensate stabilisation process

The simulation is done in Aspen Plus software and has a report and detailed economic analysis.