Introduction

Following a comprehensive analysis and simulation of the Ethanol Dehydration Process، using the Non-Random Two Liquid (NRTL) model, this study delves into the process using the Universal Quasi-Chemical Activity Coefficient (UNIQUAC) thermodynamic model.

Given its ability to account for non-ideal interactions between mixture components, the UNIQUAC model is anticipated to offer enhanced accuracy in predicting phase behavior and mixture separation, especially under complex conditions.

Introductions to Ethanol Dehydration Process

Ethanol, a widely used chemical, is difficult to separate from water due to their azeotropic formation. This means they boil together at a constant temperature, making traditional distillation ineffective. To overcome this, a third substance, called an Solvent, is added to the mixture. This Solvent changes the boiling points of ethanol and water, allowing them to be separated. Common Solvent include benzene and cyclohexane.

Using the UNIQUAC Model in Simulation

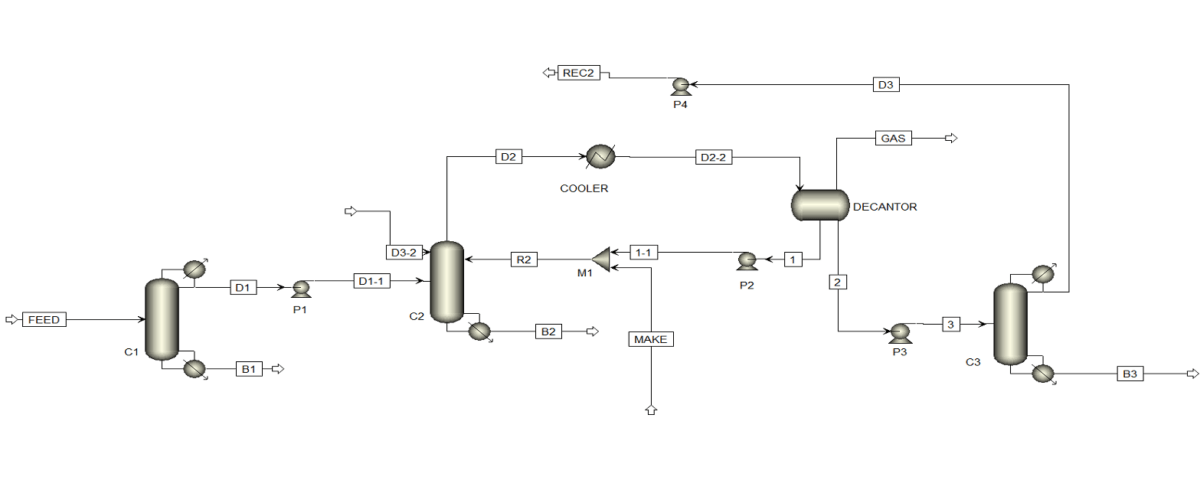

This project employed the UNIQUAC thermodynamic model within the Aspen Plus software to simulate the heterogeneous dehydration of ethanol.

By accounting for non-ideal interactions between components with greater precision than the NRTL model, UNIQUAC offers enhanced accuracy in predicting the phase behavior of mixtures involved in this process.

Simulation Steps and Results Analysis

Component Definition and Thermodynamic Model Selection

The primary components of the mixture (ethanol, water, and solvent) were defined in the software, and the UNIQUAC thermodynamic model was selected for the simulation.

Operational Conditions Setup

Similar to the previous project, the operating temperature and pressure for each process section were specified, and the required physical and thermodynamic data were input into the software.

Distillation Column Simulation

The process involved three main columns: a pre-concentrator, an azeotropic column, and a recovery column. Each column was simulated using the UNIQUAC model to examine the behavior of ethanol separation from water using a solvent.

Results Analysis

Simulation results indicated that the UNIQUAC model demonstrated remarkable performance in predicting phase behavior and the final purity of ethanol. The ethanol purity obtained in this simulation was slightly higher, and the operating conditions were more optimal compared to the NRTL model.

conclusion

This project showed that the use of the UNIQUAC model in the simulation of the heterogeneous ethanol dehydration process can provide more accuracy in predicting the phase behavior of the system and optimizing the process.

Choosing the right thermodynamic model can have a significant impact on process efficiency.

Related Projects

SANILCO Company has successfully completed several projects in the field of heterogeneous ethanol dehydration, including:

-

Aspen Plus Simulation of Heterogeneous Ethanol Dehydration

This project involved simulating the heterogeneous dehydration process of ethanol using Aspen Plus versions 10 and 12, based on the methods and data from a research paper. The focus was on analyzing and optimizing operational parameters. -

Improving Heterogeneous Ethanol Dehydration Simulation Using Data Regression in Aspen Plus

In this project, the simulation of heterogeneous ethanol dehydration was enhanced using data regression in Aspen Plus to increase simulation accuracy and achieve better results. The focus was on analyzing and optimizing operational parameters. -

Simulation and Optimization of Ethanol-Water Separation in Aspen Plus

This research involved simulating and optimizing the heterogeneous dehydration process of ethanol using Aspen Plus, with the goal of generalizing the results to an industrial unit. The primary objective was to reduce operational costs and increase energy efficiency, considering real-world industrial conditions. -

Dynamic Simulation of Heterogeneous Ethanol Dehydration Process with Aspen Plus This project described the dynamic simulation of the heterogeneous ethanol dehydration process using Aspen Plus Dynamics. The goal was to analyze the dynamic behavior of the process and optimize operating conditions and control systems

In this project, the simulation of ethanol dehydration process has been done using UNIQUAC model using Aspen Plus software.